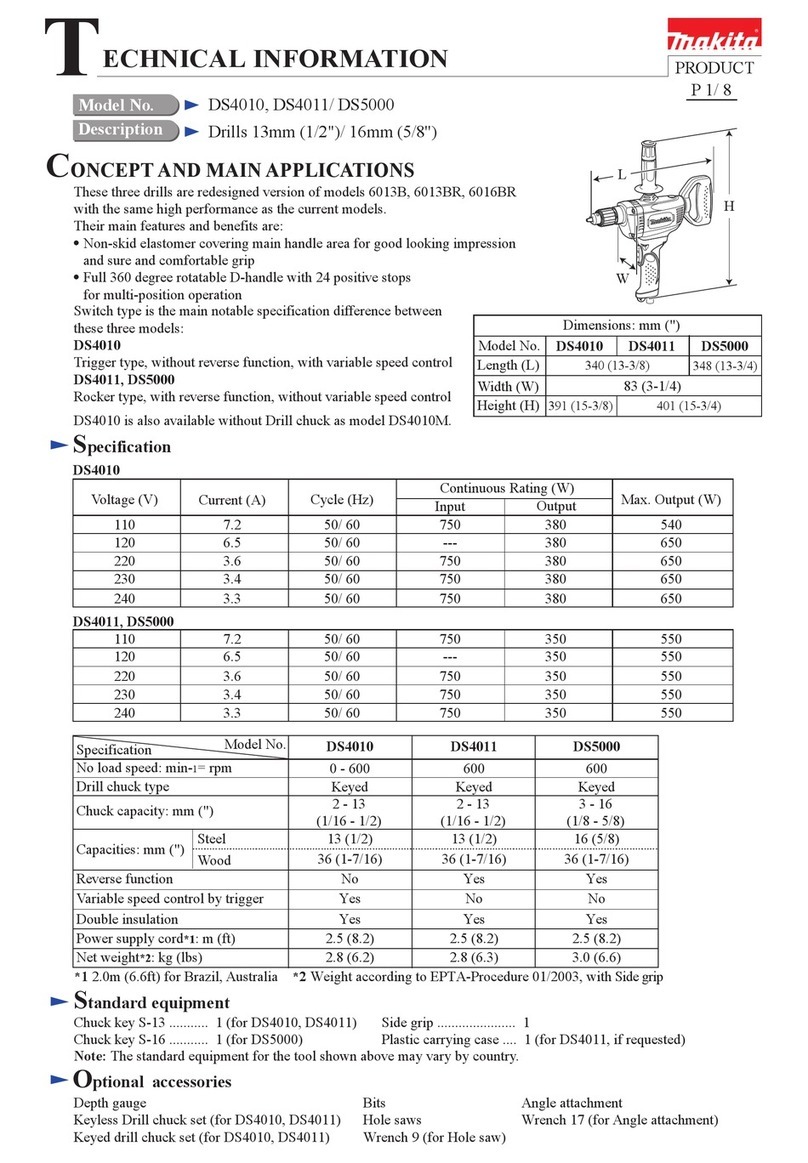

Models No.

Description

PRODUCT

TECHNICAL INFORMATION

CONCEPTION AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may be differ from country to country.

8443D, 8433D, 8413D

Cordless Percussion Driver drill

Mod.8443D: 18V percussion version of existing Mod.6343D.

Its action mode change ring (screwdriver - drill- percussion)

can be operated independently of torque adjusting

ring for easy operation. Equipped with one sleeve chuck.

Mod.8433D: 14.4V version of Mod.8443D. Its features are

same as Mod.8443D.

Mod.8413D: 12V version of Mod.8443D. Its features are same

as Mod.8443D.

Model No. Battery Charger

8443DWAE

8443DWDE

8443DWFE

8433DWAE

8433DWDE

8433DWFE

8413DWAE

8413DWDE

8413DWFE

1822 : 2 pcs

1834 : 2 pcs.

1835 : 2 pcs.

1422 : 2 pcs.

1434 : 2 pcs.

1435 : 2 pcs.

1222 : 2 pcs.

1234 : 2 pcs.

1235 : 2 pcs.

DC1801

DC1801

DC1801

DC1411

DC1411

DC1411

DC1411

DC1411

DC1411

Dimensions in mm (")

Model No.

8443D 267

(10-1/2)

8433D

8413D

267

(10-1/2)

267

(10-1/2)

LHW

249

(9-13/16)

244

(9-5/8)

240

(9-1/2)

95

(3-3/4)

94

(3-11/16)

94

(3-11/16)

L

H

W

Model No.

Voltage ( V )

Chuck ability (mm)

No load speed

(min-1= rpm.)

High

Low

Blows per min.

(bpm.)

High

Low

in Stone

Drilling

capacity

in Steel

in Wood

Torque adjustment

Max.fastening torque

Adjustable torque

in 16 stage

16 stage and drill mode

1Nm - 6 Nm

(10Kgfcm - 60Kgfcm)

(0.7ft.lbs - 4.4ft.lbs)

45Nm

(460Kgfcm)

(33ft.lbs)

38Nm

(390Kgfcm)

(28ft.lbs)

32Nm

(330Kgfcm)

(24ft.lbs)

8443D 8433D 8413D

18 14.4 12

1.5 (1/16") - 13 (1/2")

0 - 1,400

0 - 450

0 - 21,000

0 - 6,750

13 mm (1/2")

38 mm (1-1/2")

16mm (5/8")

0 - 1,300

0 - 400

0 - 1,300

0 - 400

0 - 19,500

0 - 6,000

0 - 21,000

0 - 6,750

* Battery cover ........................ 2 pcs. * Stopper pole assembly........... 1 pc.

* Grip assembly........................ 1 pc. * + - Bit 2-45 ............................2 pcs.

* 18 V battery ................ 2 pcs. * Carrying case ....................... 1 pc.

* Various TCT. bits * Safety goggle * Blow-out bulb

* Battery 1834 (NiMH, 2.6Ah)

* Battery 1835 (NiMH, 3.0Ah)

* Variation of Mod. 8443D, 8433D and 8413D

13 mm (1/2")

13 mm (1/2")

36 mm (1-7/16") 30 mm (1-3/16")

14 mm (9/16") 13 mm (1/2")