P 3/ 20

Repair

CAUTION: Remove the battery and the bit from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R003

1R038

1R212-A

1R212-B

A-43240 Socket 19-52

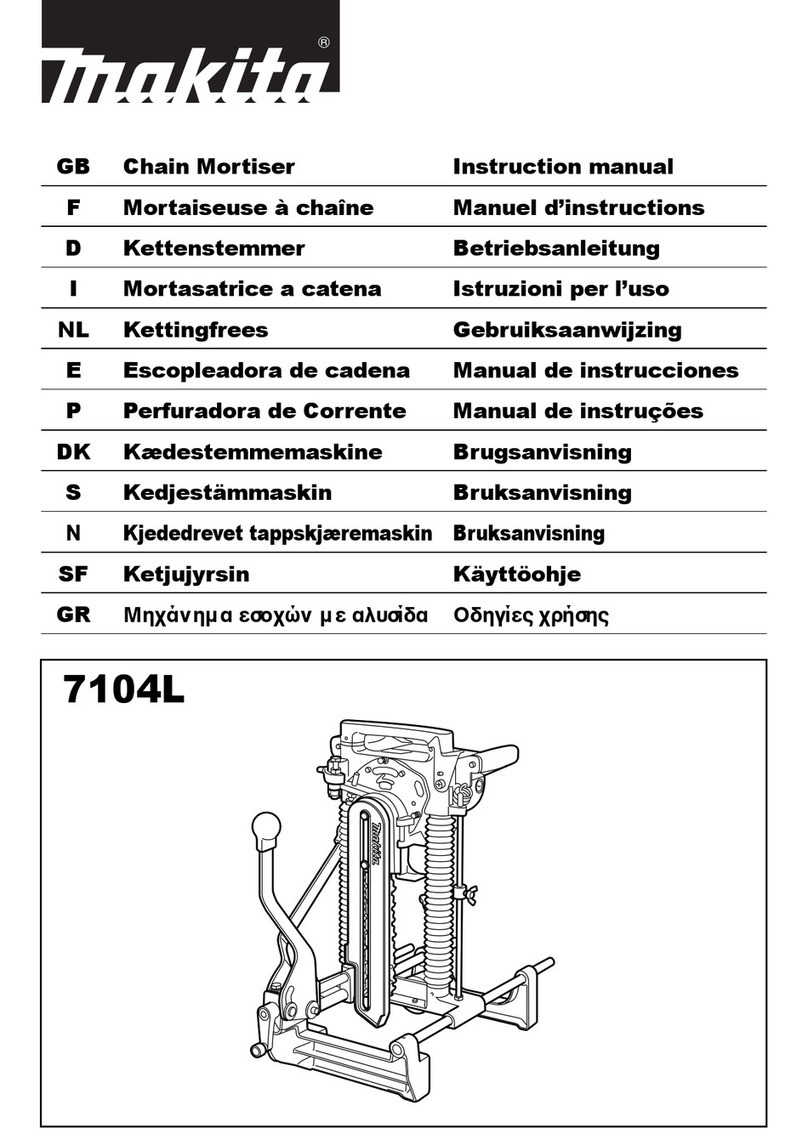

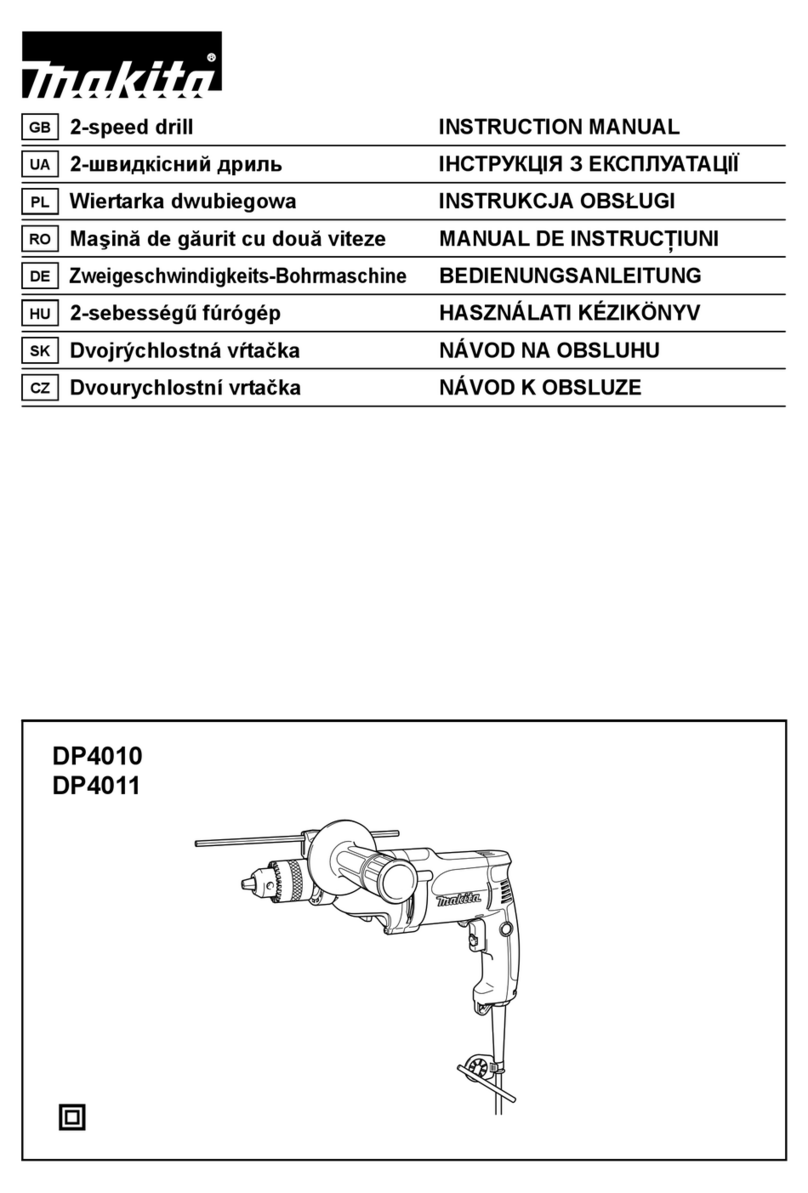

[2] LUBRICATION

Fig. 1

Item No. Description AmountPortion to lubricate

RETAINING RING PLIERS ST-2N Removing / Mounting Ring spring 10 (for DF032D)

ARMATURE HOLDER 32 SET Holding Socket 19-52, when removing Drill chuck

TIP FOR RETAINING RING PLIERS Attaching to 1R003 in order to remove / to mount Ring spring 10

(for DF032D)

1/4" HEX.SHANK BIT FOR M8

Hex wrench 8

Bit adapter

Nut spinner handle 12.7 mm

< Note >

If it is compelled to disassemble Gear assembly in the step of replacement of Drill chuck,

lubricate gears, as need arises. However, in case of trouble on Gears, replace Gear assembly

as an assembly parts.

PLATE SET (WITH SCREWS)

1R231 Removing drill chuck (for DF332D, HP332D)

Removing drill chuck (for DF332D, HP332D)

Removing / Mounting drill chuck (for DF332D, HP332D)

Apply Makita grease FANo.2 to the portions designated with the black triangle.

(a)

(b)

(b)

(a)

Ring gear 44

Ring gear 40

Rear housing

Ring gear 44 Spur gear 17-40

complete

(e)

(d) Spur gear 17-40 complete

(d)

(e)

(c)

Spur gear 13 complete

Spur gear 15

Spur gear 11 Teeth portion

Teeth portion

Teeth portion

Teeth portion

a little

a little

a little

a little

(c)

Index

[1] NECESSARY REPAIRING TOOLS P 3

[2] LUBRICATION

[3]-1 Drill chuck (HP332D, DF332D) P 4

[3]-2 Gear case assembly, Motor section P 10

[3]-3 Bit holder section (DF032D) P 14

[3]-4 Change lever assembly P 15

[4] Trouble shoot P16

Trouble Shooting using Tester

[4] Check list for Trouble Shooting P 17

Circuit diagram P 18

Wiring diagram P 19

Wiring diagram

Circuit diagram and Wiring of Replaced LED light circuit P 20