[3] DISASSEMBLY/ASSEMBLY

[3]-2. Motor section

DISASSEMBLING

ASSEMBLING

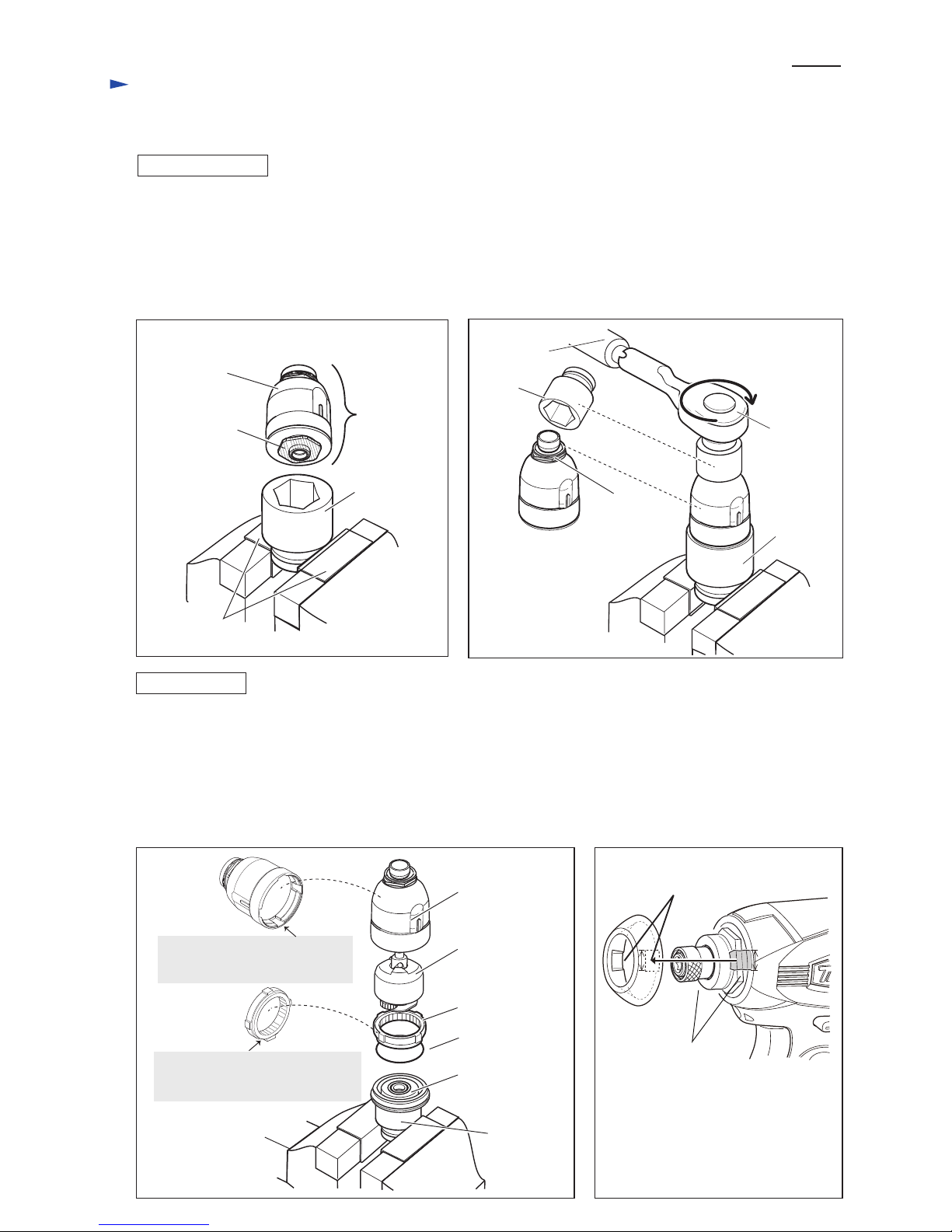

Fig. 12

Fig. 13

Fig. 14

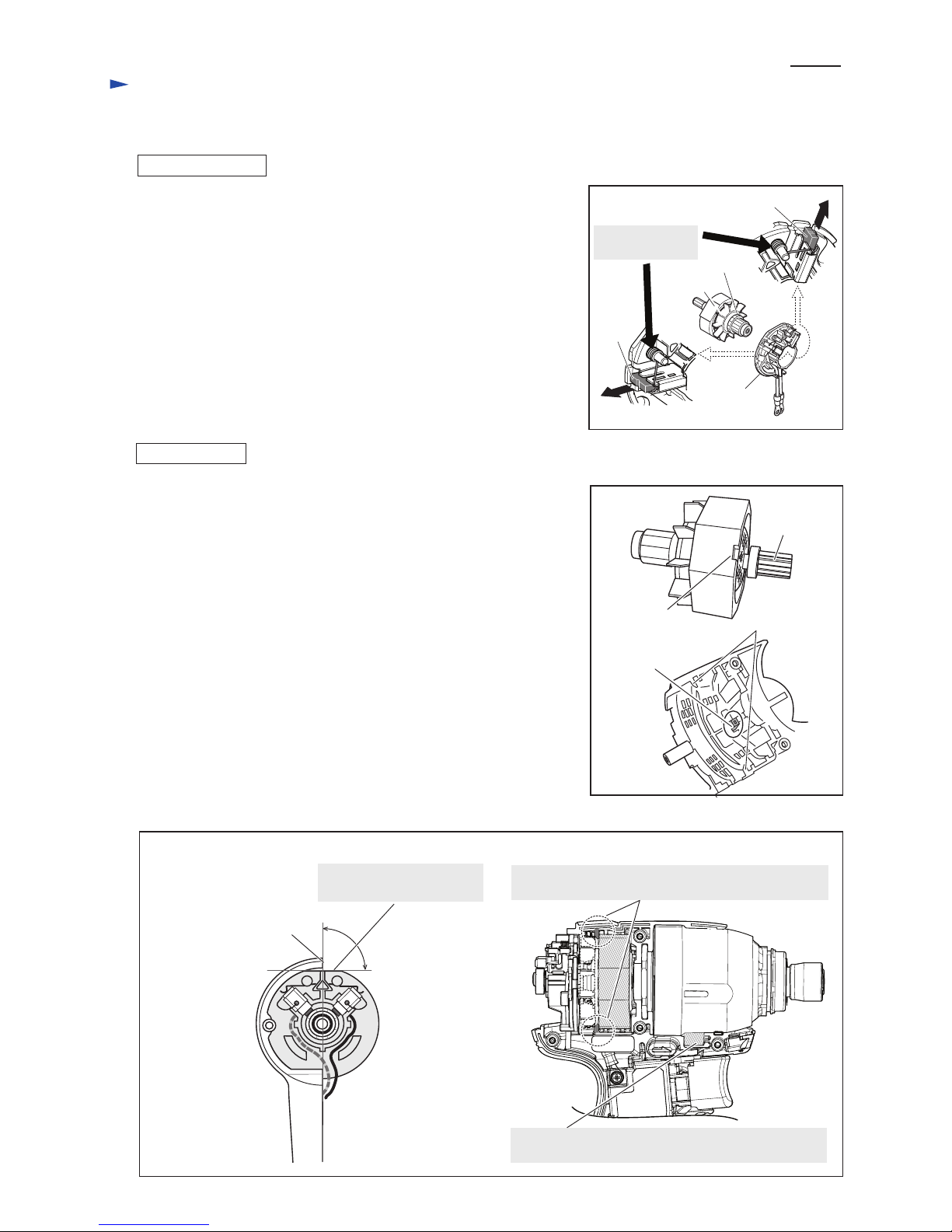

(1) Remove Hammer section by steps drawn in Fig. 2 to Fig. 7.

(2) Release tail of each Torsion spring from Carbon brushes and

hook these tails into the grooves around the edges of Brush holder.

(Fig. 12)

(3) Keep Carbon brushes apart from the commutator of Armature. (Fig. 12)

(4) Hold the coils of Torsion springs not to be removed, and pull out

Armature and Yoke unit together from Brush holder complete.

(Fig. 12)

Take the disassembling step in reverse.

Note: • When passing Armature through Yoke unit, make sure that

the notch on Yoke unit is positioned on Armature drive end.

(Fig. 13)

Because Armature is attracted to magnet of Yoke unit,

be careful to hold them not to pinch fingers and prevent the coils

against damage.

• When assembling the motor section to Bearing box complete,

insert Armature drive end into Internal gear 51 engaging with

Spur gears 22 . (Figs. 13 and 1)

• When the assembled sections (Hammer section, motor section and

Brush holder section) is set on Housing set (L), fit the projection

of the housing into the notch on Yoke unit. (Figs. 13 and 6)

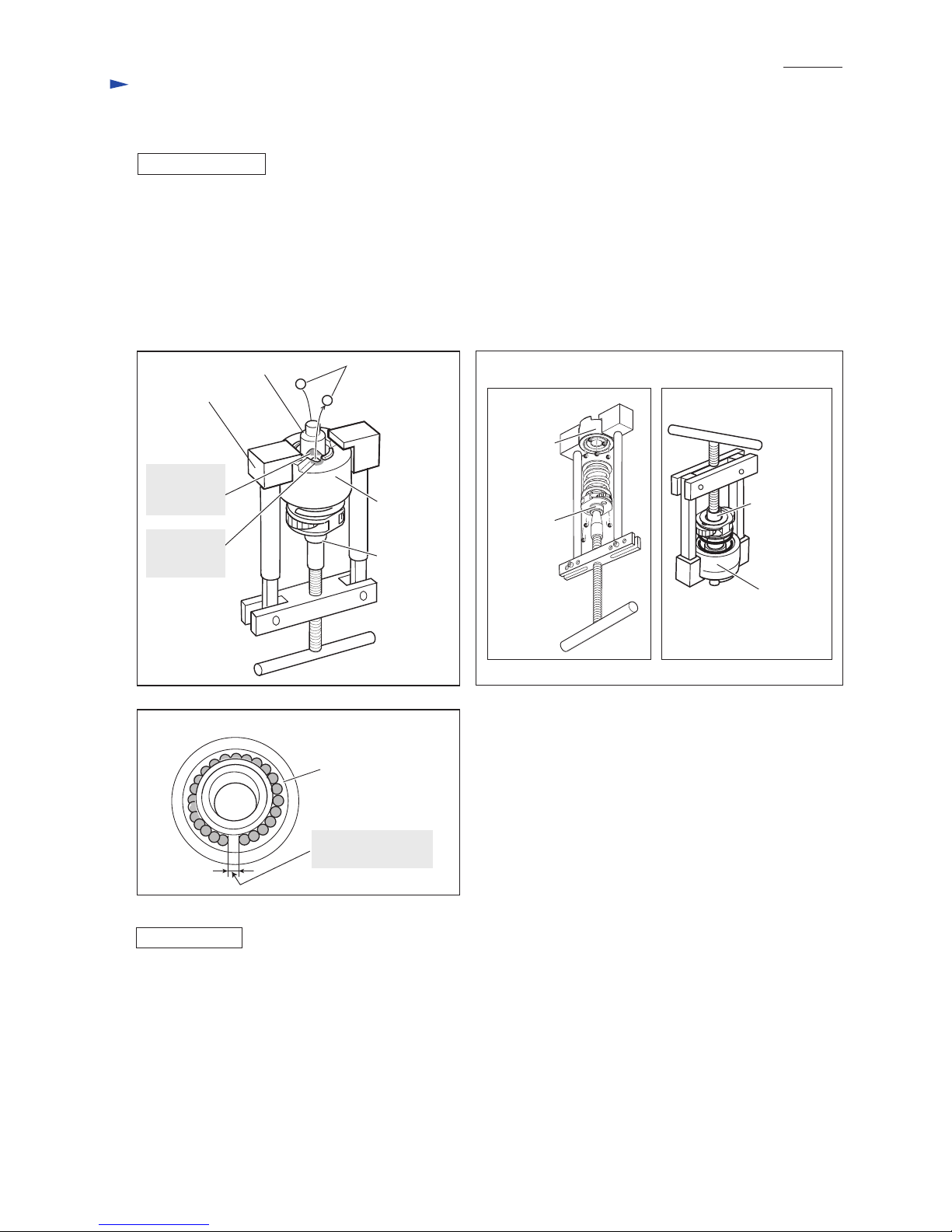

• Be sure to check the following positions as drawn in Fig. 14.

(1) Flat portion of Brush holder complete

(2) Ribs on Housing set (L)

(3) Projection on Hammer case complete

P5/ 11

Repair

Carbon brush

Hold the coils of

Torsion springs.

Carbon

brush

Armature

drive end

Notch on

Yoke unit

Projection on

Housing set (L)

Brush holder

complete

Armature

Yoke unit

90

°

(1) flat portion of

Brush holder complete

Brush holder complete

viewed from the rear side

(2) Yoke unit end has to be attached to the right side

of the ribs of Housing set (L).

(3) Projection of Hammer case complete has to be

placed here that is the closest position to Switch.

edge of Housing set (L)

Ribs for

Yoke unit

(Re: Fig. 14)