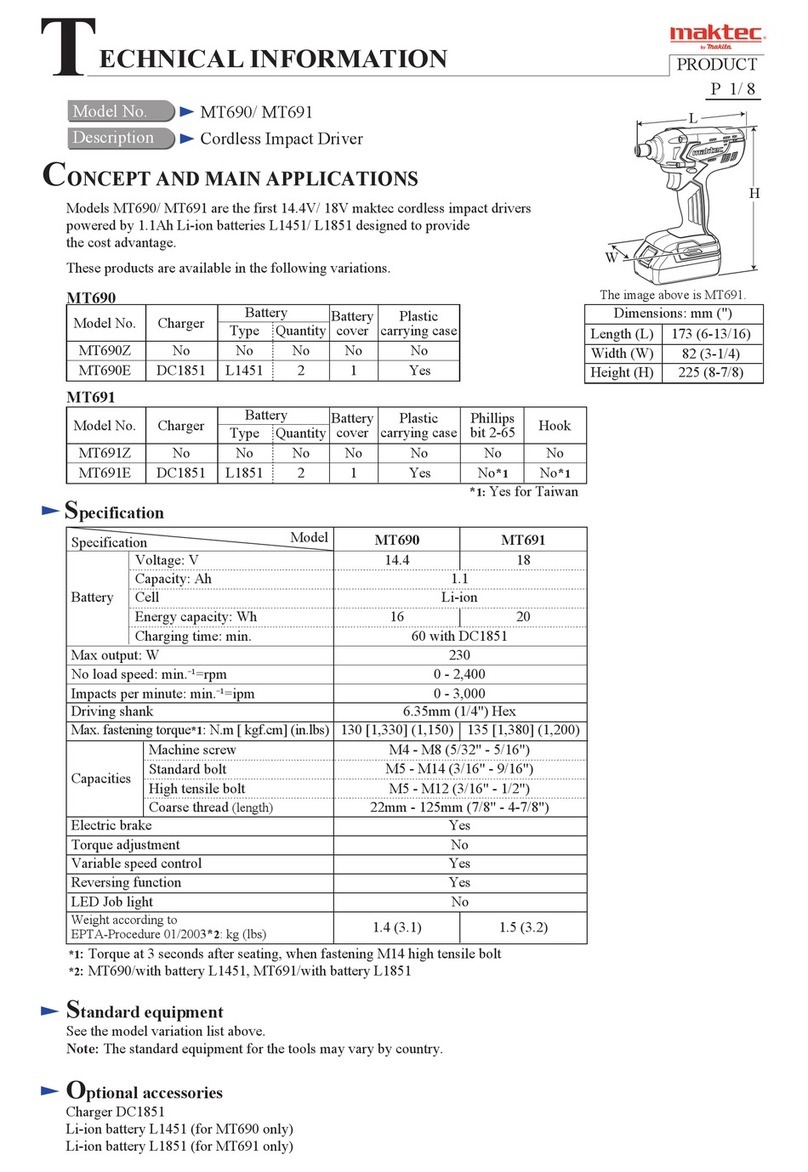

Features and benefits P 4 / 9

Indications and functions

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A0 - 9

BSelect any of

0 - 9

Select any of

0 - 9

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

C

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

Special purpose

Dial pre-selection Clockwise rotation Anti-clockwise rotation

Mode of reverse switch

If the dial of second digit is set on "A", the machine does not

start in spite of pulling trigger switch, or setting the dial of

first digit on any numbers.

Purpose

The machine stops after the

sensor perceives the first blow,

depending on the pre-selected

figures of the first digit.

For instance,

0 : Stop at one

1 : Stop 0.1 sec. later

2 : Stop 0.2 sec. later

9 : Stop 0.9 sec. later

The machine starts or stops

with operation of the trigger

switch.

Preliminary fastening

of bolts

The machine starts or stops

with operation of the trigger

switch.

Loosening of bolts

The machine stops after

stopping its blow, depending

on the pre-selected figures

of the first digit. For instance,

0 : Stop at one

1 : Stop 0.1 sec. later

2 : Stop 0.2 sec. later

9 : Stop 0.9 sec. later

The second

digit

The first

digit

The second

digit

The first

digit

The second

digit

The first

digit

0 - 9

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

D

E

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

Select any of

0 - 9

The second

digit

The first

digit

The second

digit

The first

digit

The machine does not start in

spite of pulling trigger switch,

but buzzers 0.2 sec. depending

on the pre-selected figure of

the first digit after pulling

trigger switch, . For instance,

0 : one time buzzer

1 : two times buzzer

2 : three times buzzer

9 : ten times buzzer

Checking the functions

mentioned below.

For instance

* BPM. pre-select dial

* Stop of motor

* Buzzer

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

Select 0 and 1

The second

digit

The first

digit

If the dial of second digit is set on "D", the machine does not

start in spite of pulling trigger switch, or setting the dial of

first digit on any numbers.

The machine starts, and stops

depending on the pre-selected

figure of the first digit after the

sensor perceives how many

times you have hit the housing,

For instance,

0 : stop with one time hitting

1 : stop with two times hitting

2 : stop with three times hitting

9 : stop with ten times hitting

If the dial of second digit is set on "F" and the same of the first

digit is set on zero or one, the following matters are informed.

0 : information of the version code of program

* Version code 2.1 : two long buzzers - long pause,

- one short buzzer

* Version code 3.2 : three long buzzers - long pause,

- two short buzzers

1 : information of the remaining voltage as follows.

* 23 V : two long buzzers - long pause - three short buzzers

* 20 V : two long buzzers

* 18 V : one long buzzer - long pause - eight short buzzers

* 9 V : nine short buzzers

Checking the version

code of program in the

controller

and

remaining voltage of

battery