10 ENGLISH

ENGLISH (Original instructions)

SPECIFICATIONS

Model: DUA300

Overall length (without guide bar and attachment) 2,235 mm

Rated voltage D.C. 36 V

Net weight *1 6.2 kg

*2 6.1 - 7.4 kg

Standard guide bar length 300 mm

Recommended guide bar

length

with 90PX 250 - 300 mm

with 91PX 250 - 300 mm

Applicable saw chain type

(refer to the table below)

90PX

91PX

Standard sprocket Number of teeth 6

Pitch 3/8″

Chain speed 0 - 20 m/s

(0 - 1,200 m/min)

Chain oil tank volume 160 cm3

• Duetoourcontinuingprogramofresearchanddevelopment,thespecicationshereinaresubjecttochange

without notice.

• Specicationsmaydierfromcountrytocountry.

*1: Weight, with largest battery cartridge and empty oil tank, and without guide bar, chain, shoulder harness, and

attachment, according to EN ISO11680-1.

*2:Thelightestandheaviestcombinationofweight,accordingtoEPTA-Procedure01/2014.Theweightmaydier

depending on the attachment(s), including the battery cartridge.

Applicable battery cartridge and charger

Battery cartridge BL1820B / BL1830B / BL1840B / BL1850B / BL1860B

Charger DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF /

DC18SH / DC18WC

• Some of the battery cartridges and chargers listed above may not be available depending on your region of

residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

andchargersmaycauseinjuryand/orre.

Recommended cord connected power source

Portable power pack PDC01 / PDC1200

• The cord connected power source(s) listed above may not be available depending on your region of residence.

• Before using the cord connected power source, read instruction and cautionary markings on them.

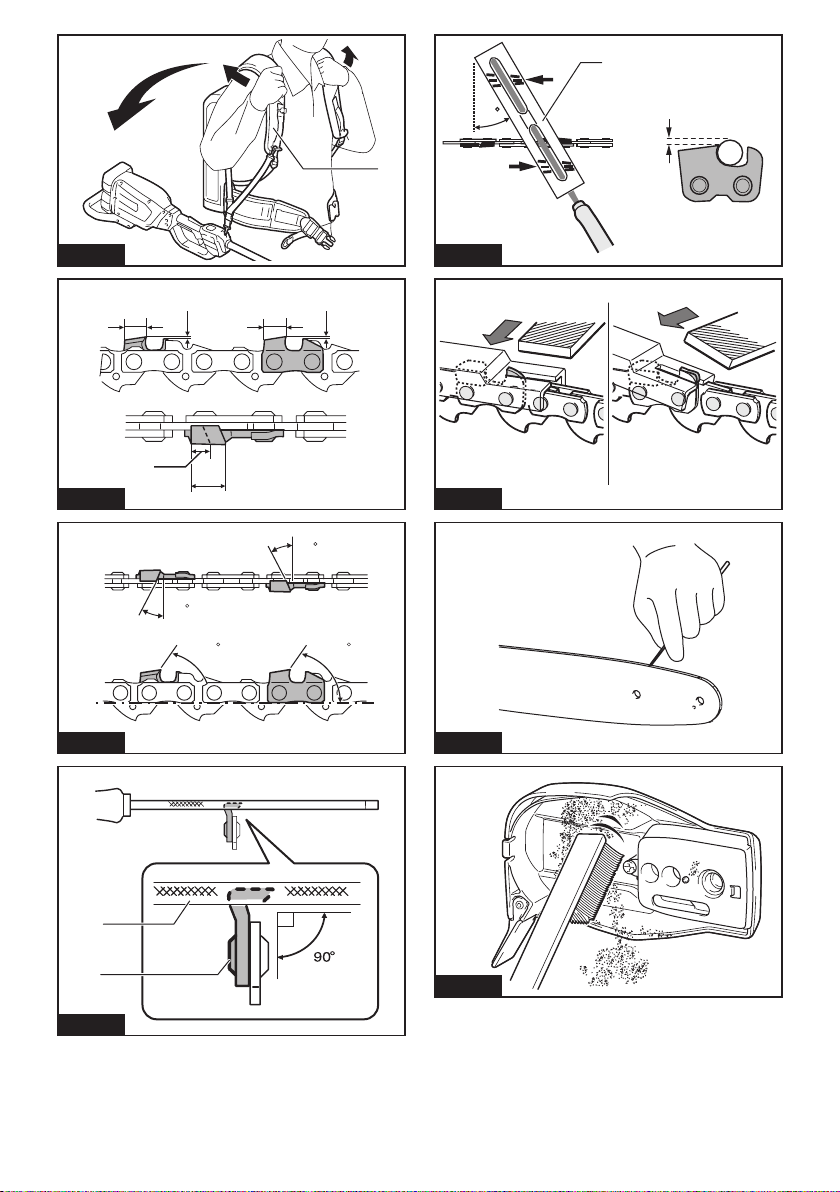

Saw chain, guide bar, and sprocket combination

Saw chain type 90PX

Number of drive links 46

Guide bar Guide bar length 300 mm

Cutting length 296 mm

Pitch 3/8″

Gauge 1.1 mm

Type Sprocket nose bar

Sprocket Number of teeth 6

Pitch 3/8″