Makita HR2000 User manual

Other Makita Rotary Hammer manuals

Makita

Makita HR5201C User manual

Makita

Makita HR005G User manual

Makita

Makita HR2610T User manual

Makita

Makita HR2230 User manual

Makita

Makita HR2300X9 User manual

Makita

Makita HR2230 User manual

Makita

Makita HR005GZ01 User manual

Makita

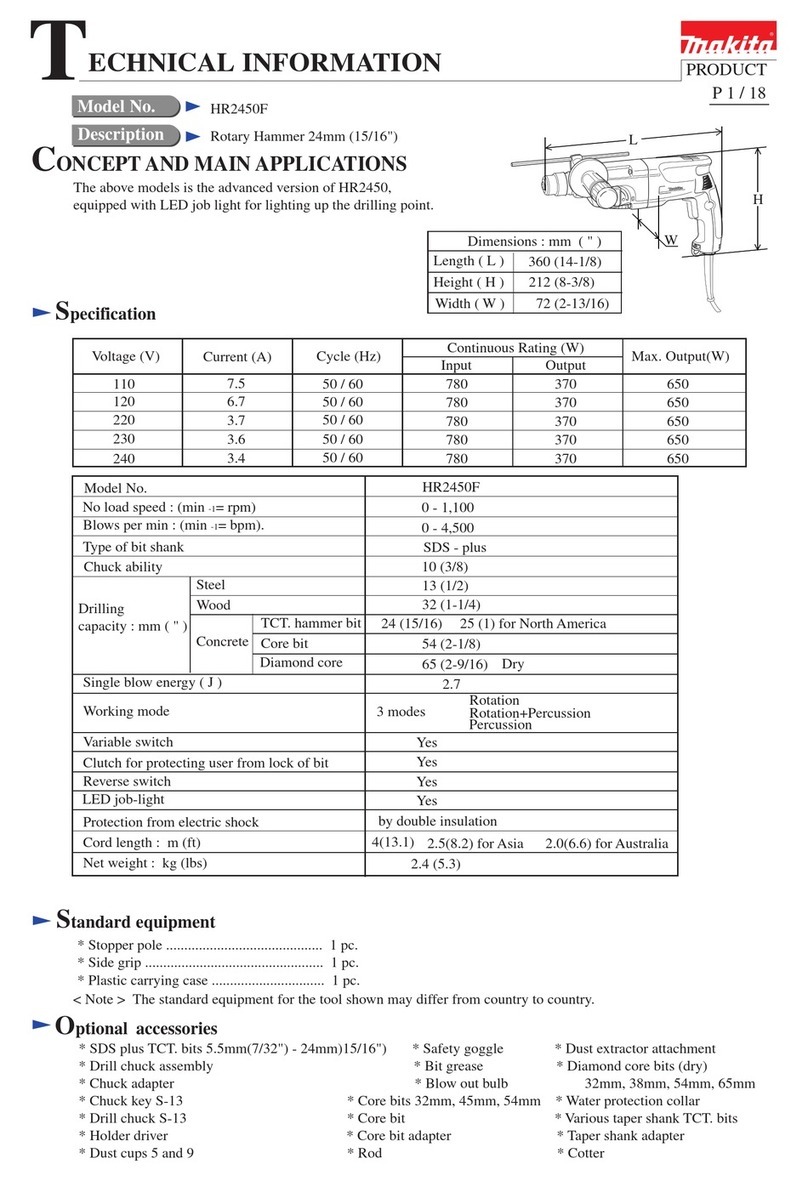

Makita HR2450F User manual

Makita

Makita BHR162 User manual

Makita

Makita HK0500 User manual

Makita

Makita HR1840 User manual

Makita

Makita HR5000 User manual

Makita

Makita DHR400 User manual

Makita

Makita HR2450F User manual

Makita

Makita HR1830 User manual

Makita

Makita HR2450F Manual

Makita

Makita HR4041C User manual

Makita

Makita HR2230 User manual

Makita

Makita HR3200C User manual

Makita

Makita HR2450 Series User manual

Popular Rotary Hammer manuals by other brands

BorMann

BorMann BPH7000 Translation of the original instructions

Metabo HPT

Metabo HPT DH 3628DD Safety instructions and instruction manual

Black & Decker

Black & Decker KD650 manual

Bosch

Bosch GBH Professional 2-20 DRE Original instructions

Bosch

Bosch 2-26 E operating instructions

BTI

BTI Profiline BTI-BH 24 VE operating instructions