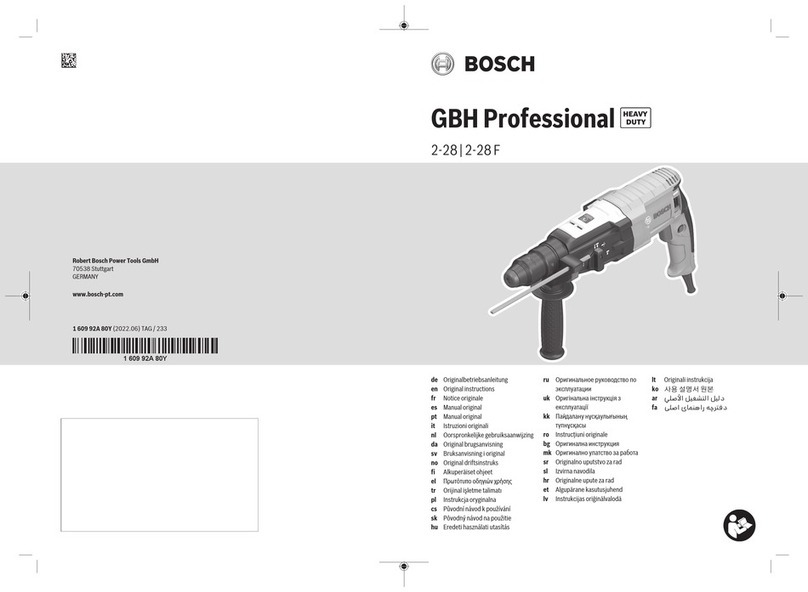

2-1. Disassembling of barrel

Remove the hexagon socket bolt M5x20 and then remove

the barrel.

Use the arbor press to press the top of tool holder to

remove it.

2-2. Assembling of barrel

Assemble in a way that the trace of pusher pin shown on

the right figure comes at name plate side.

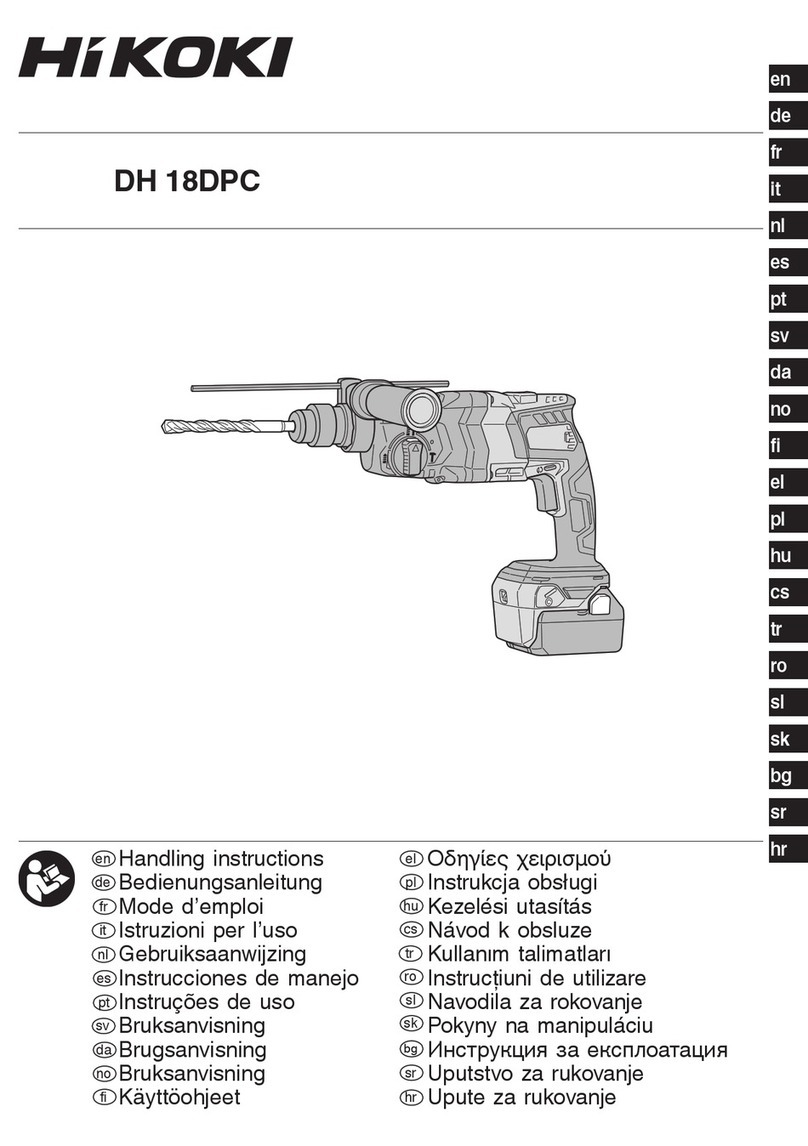

3-1. Disassembling of impact bolt

Use the screw driver to shift the impact bolt in the direction of tool holder edge as shown on the bottom-

right figure.(in the direction of arrow 1)

Use the resin hammer to slightly hammer the tool holder as shown on the bottom-right figure to remove

the four points of steel ball 5 and 6.

Use the sharpened-edge tool like an eyeleteer to pull out

the O ring 11 as shown on the bottom-right figure. For

easy disconnection, use the eyeleteer while 5 mm around

of sharpened-edge tool edge is being bent by 90"around.

Use the driver edge to disconnect(push) the impact

bolt.(in the direction of arrow 2

3-2. Assembling of impact bolt

Use the screw driver to insert the impact bolt into the tool

holder.

Use the sharpened-edge tool to insert the O ring 11 into the

groove of the tool holder. Move the impact bolt in the direction

of arrow to check if O ring 11 cannot be disconnected.

Before placing the steel ball 5 and 6 in the tool holder, grease

into the hole so that the steel ball cannot drop and the tool

holder can be easily set.

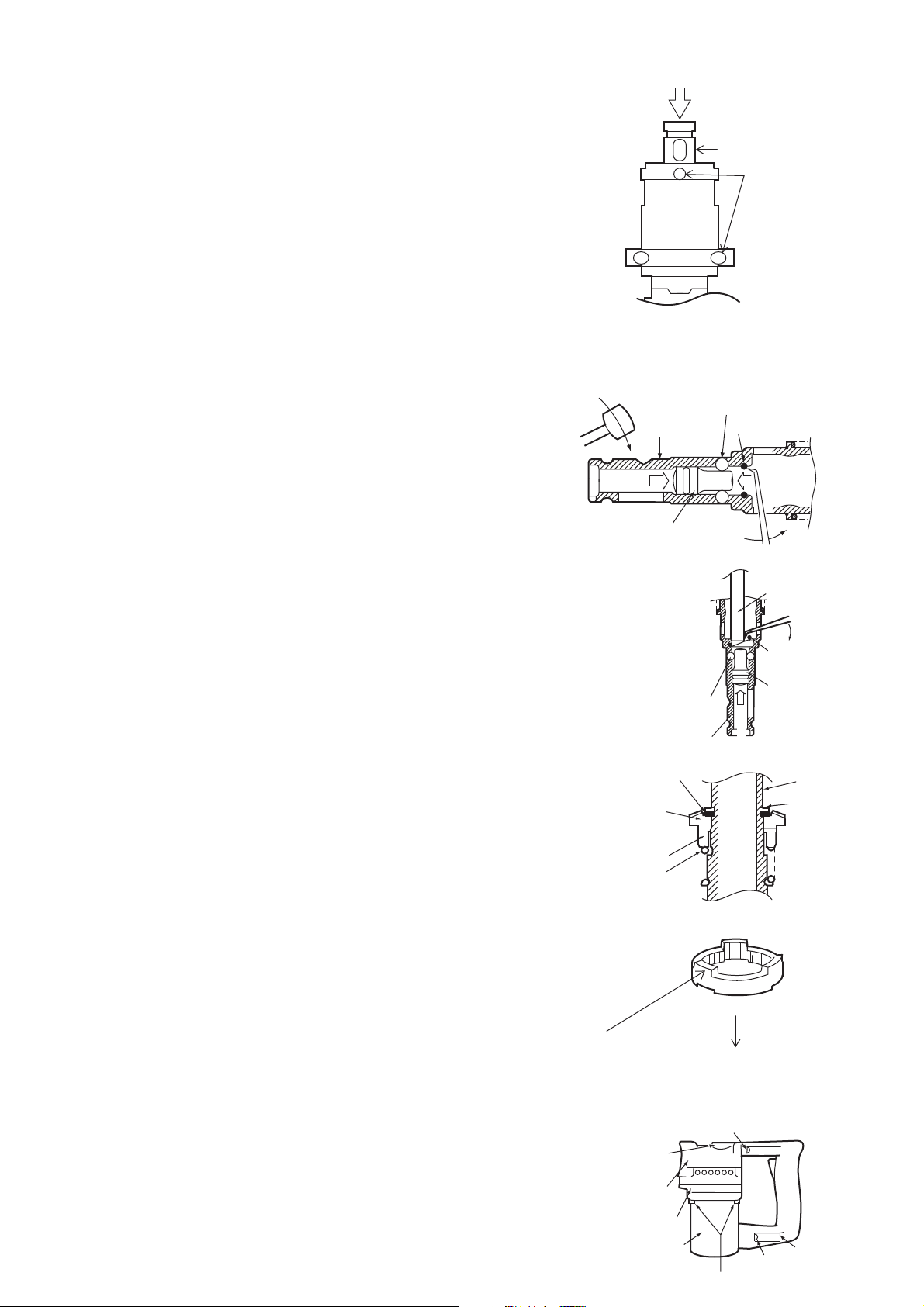

4-1. Disassembling of torque limiter

Use the circle clip plyer to disconnect the circle clip(shaft)S-

26 and then remove the spiral bevel gear 33, clutch cam and

compression spring 31.

If hard to disconnect the parts, shift the flat washer 26 away

from the circle clip groove since it is housed in said groove.

4-2. Assembling of torque limiter

Use care of direction of clutch cam when assembling the

torque limiter.

Engage the protruded portion with the spiral bevel gear 33

while supporting the compression spring 31 by holding the

dent face.

5-1. Disassembling of crank

To disassemble the handle set, disconnect the two points of pan head screw M5X25 connected on the

crank housing complete and then disconnect the tapping

screw PT5x25 connected on the motor housing complete.

To disassemble the motor housing complete, disconnect the

hexagon holed bolt M5x45 connected on the gear housing

complete and crank housing complete.

Separate the crank housing from the gear housing.

Use the lock nut wrench 28 to disconnect the crank cap.

Press

Tool holder

Trace of pusher pin

Steel ball 5 and 6

Tool holder O ring 11

Impact bolt

Press

O ring 11

Impact bolt

Steel ball 5 and 6

Tool holder

Flat washer 26 Tool holder

Circle clip

(shaft)S-26

Spiral bevel

gear 33

Clutch cam

Compression

spring 31

(Spiral bevel gear 33 side)

(Compression spring 31 side)

This protruded face is almost

the same in size as the one of

cam of spiral bevel gear 33. Direction of tool holder edge.

Arrow

Pan head screw M5x25

Crank cap

Crank housing

complete

Gear housing complete

Motor housing complete Handle set

Tapping screw PT5x25

Hexagon holed bolt M5x45