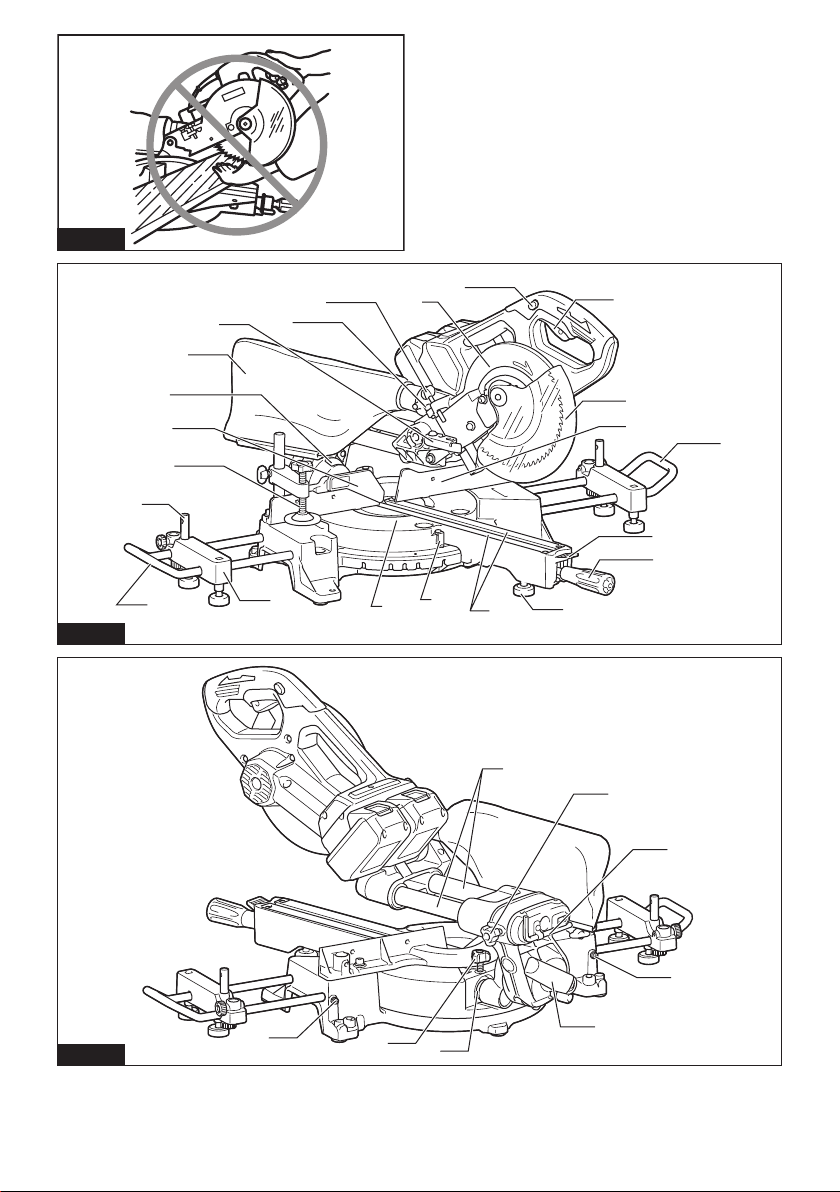

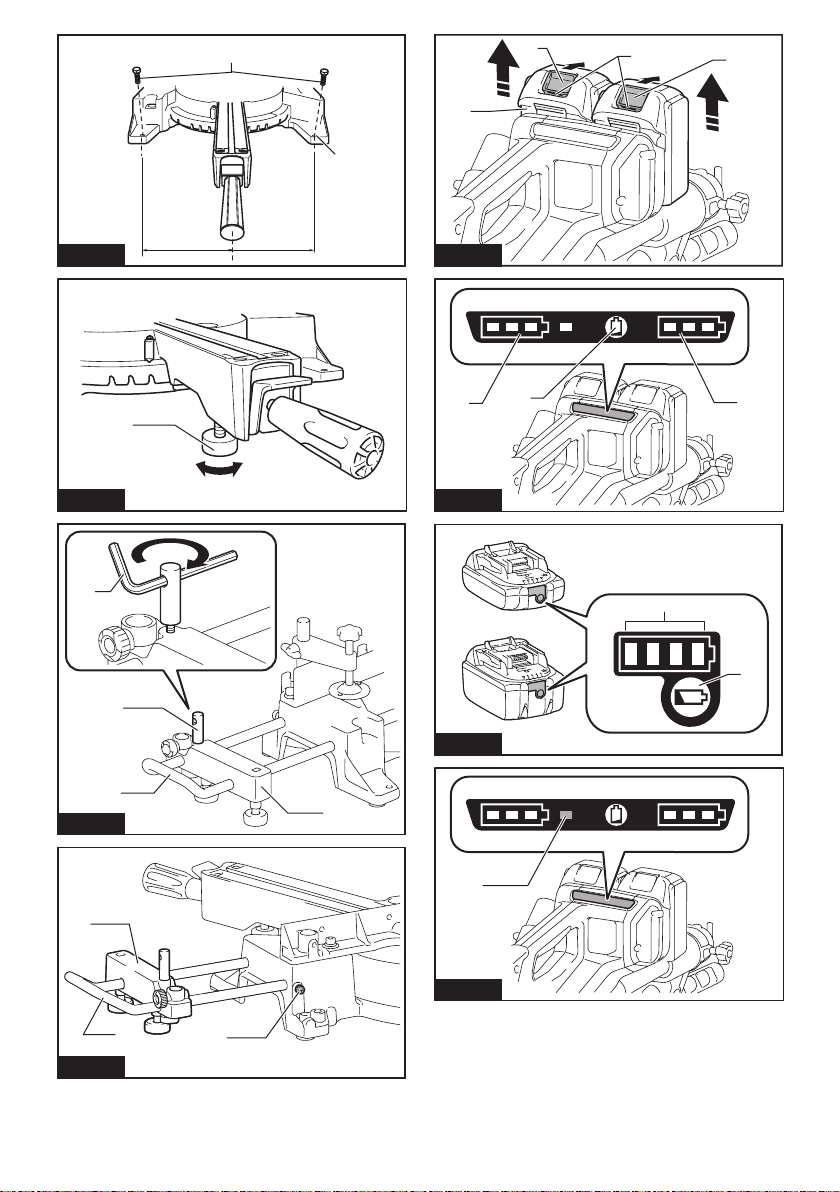

Makita DLS714 User manual

Other Makita Saw manuals

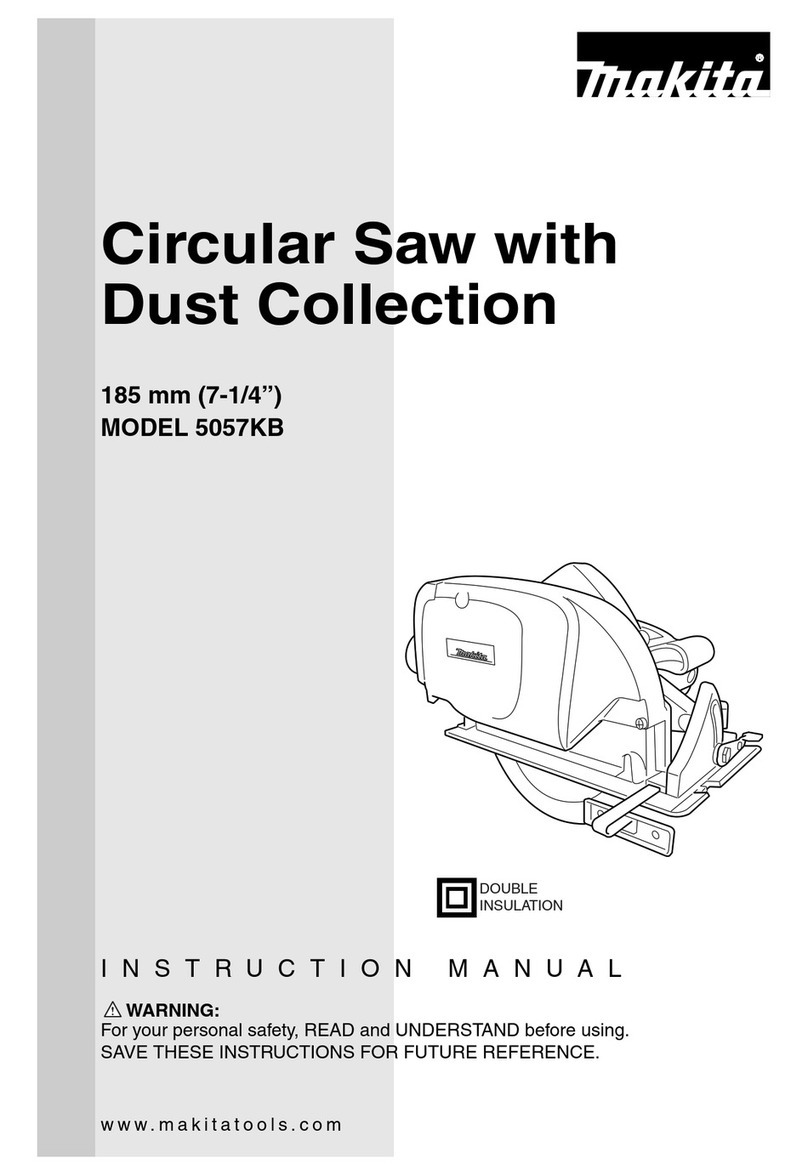

Makita

Makita M200 User manual

Makita

Makita 5008NB Operating and maintenance manual

Makita

Makita GSL03 User manual

Makita

Makita 5704R User manual

Makita

Makita JR1000FT User manual

Makita

Makita LS1030N User manual

Makita

Makita BPB180 User manual

Makita

Makita LS0714 User manual

Makita

Makita EK7650HX1 User guide

Makita

Makita 5604R User manual

Makita

Makita HS6101 User manual

Makita

Makita BJR181 User manual

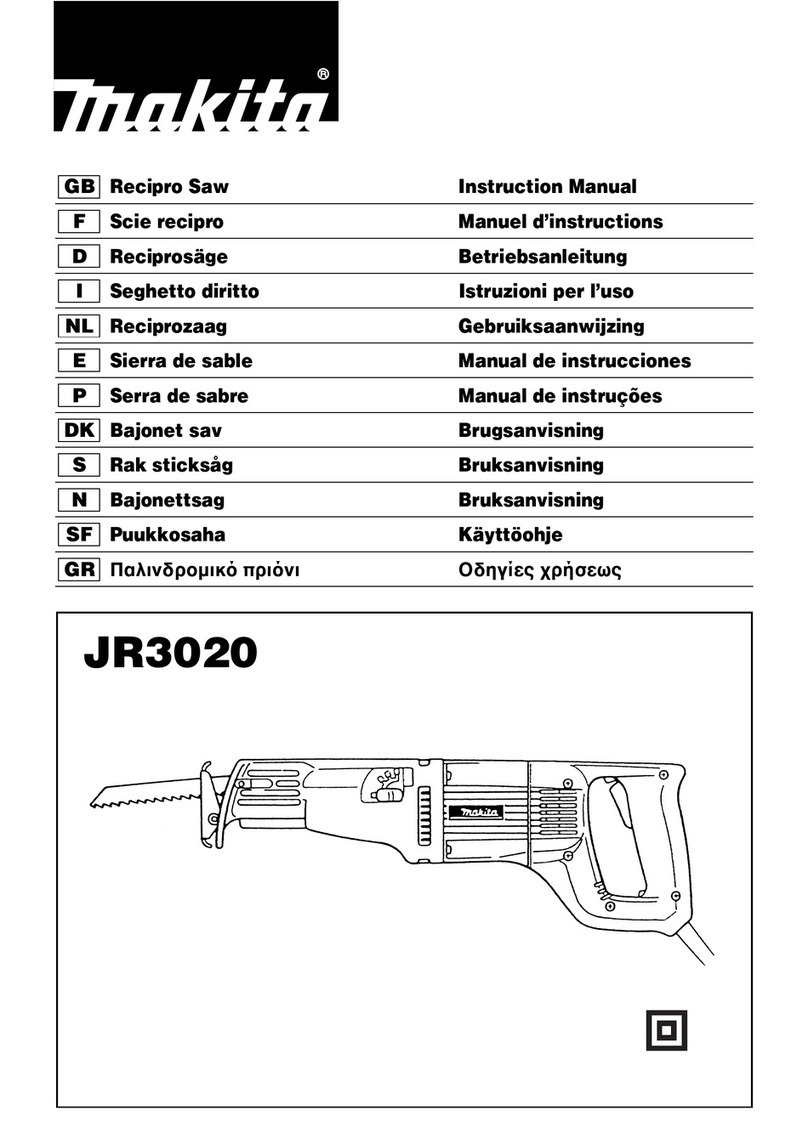

Makita

Makita DJR181 User manual

Makita

Makita 5017RKB User manual

Makita

Makita LS0815F User manual

Makita

Makita LF1000 User manual

Makita

Makita 2414B User manual

Makita

Makita JR3060T User manual

Makita

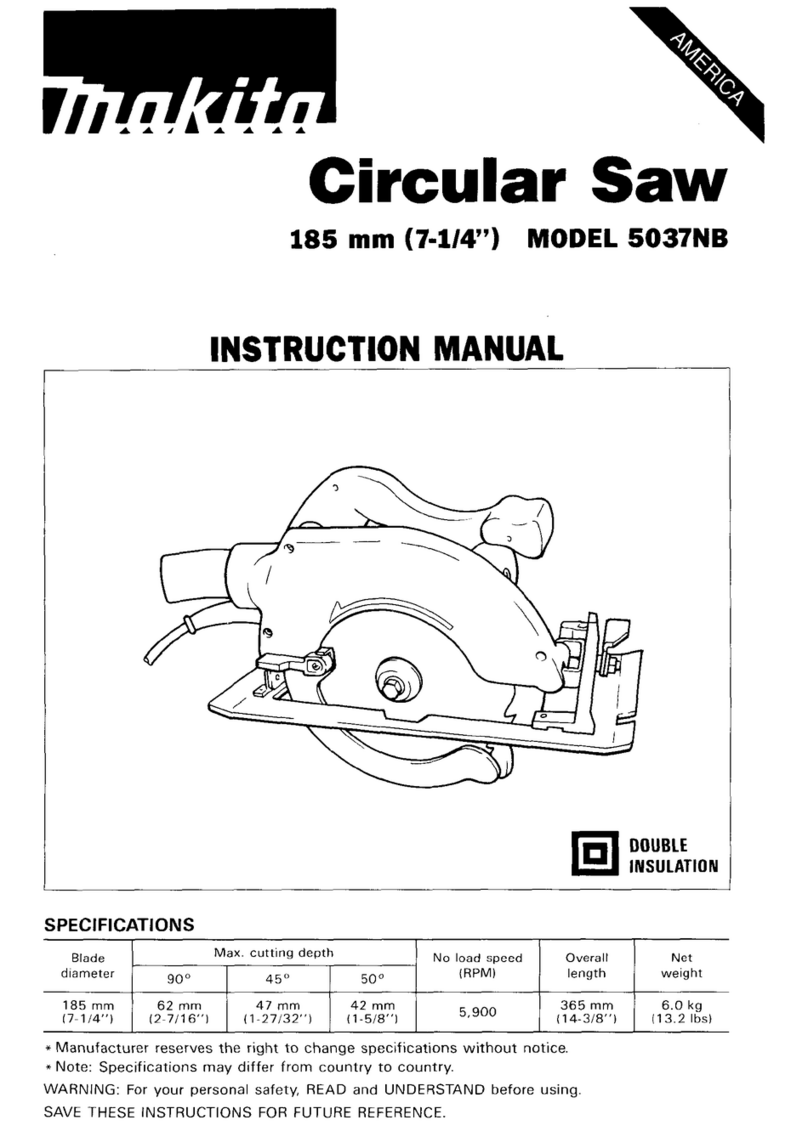

Makita 5037NB User manual

Makita

Makita LS1219 User manual