4

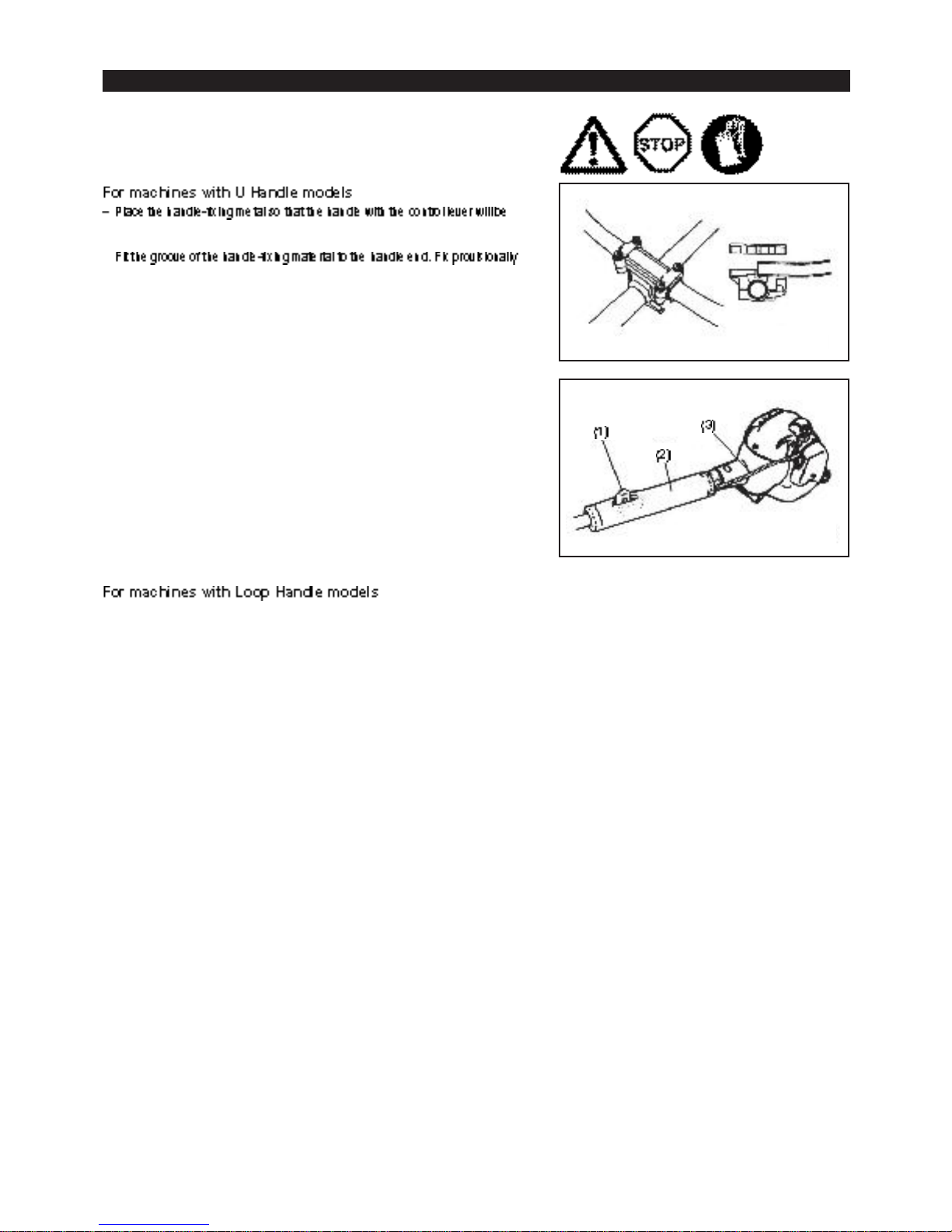

Start the Stringtrimmer only in accordance withthe instructions.

– Do notuseany other methods for starting theengine!

– Only start the String trimmerengine, afterthe entire assemblyis done.

Operationof the deviceisonly permitted after all theappropriateaccessories

are attached!

– Before starting make sure that thecutting tool has no contact withhard

objects suchas branches,stonesetc. as thecuttingtool will revolve when

starting.

– Theengine is to beswitchedoff immediately incaseof any engineproblems.

– Should the cuttingtool hit stones or other hard objects,immediately switchoff

the engine and inspect thecutting tool.

– Inspect the cuttingtoolat short regularintervals for damage (detection of

hairlinecracks by means of tapping-noise test).

– Operatethe String trimmeronly with the shoulder strap attached which is

tobe suitablyadjustedbeforeputtingthe Stringtrimmer intooperation. It is

essential toadjusttheshoulder strap accordingto theuser’s size toprevent

fatigue occurring during use. Neverhold thecutter withonehandduring use.

– Duringoperation always holdthe Stringtrimmer withbothhands.

Always ensure asafe footing.

– Operatethe String trimmerinsuchamanner as toavoid inhalation of

the exhaust gases. Neverrunthe engine in enclosed rooms (risk of gas

poisoning). Carbon monoxideis anodorless gas.

– Switchoff the engine when resting andwhenleavingtheString trimmer

unattended, andplace it in a safelocation toprevent danger to othersor

damageto the machine.

– Never put the hot String trimmerontodrygrass or ontoany combustible

materials.

Neverrunthe cutter without this guard!

– Allprotective installations and guards suppliedwiththe machinemust be

used duringoperation.

– Shut off the engine during transport.

– Duringtransport over longdistances the tool protection includedwith the

– Ensuresafepositionof theStringtrimmer during car transportationto avoid

fuel leakage.

– When transporting theString trimmer, ensure that thefuel tank is completely

empty.

– When unloadingtheStringtrimmerfrom the truck, neverdrop theEngine to

the groundor this may severely damagethefuel tank.

– Except in case of emergency, neverdroporcast the Stringtrimmer tothe

ground orthis mayseverely damagetheStringtrimmer.

Refuelling

smoke.

– Avoid skincontact withmineral oilproducts. Do not inhalefuel vapor.Always

wearprotectivegloves duringrefuelling. Changeand clean protective clothing

at regular intervals.

– Takecare not to spill either fuel or oil inorder toprevent soil contamination

(environmental protection). CleantheString trimmerimmediatelyafter fuel

has beenspilt.

– Avoid any fuel contact withyour clothing.Change your clothinginstantly if

– Inspect the fuel capat regularintervals making surethat it canbe securely

fastenedand does not leak.

– Carefully tightenthefuel tank cap. Changelocationto start theengine (at

least 3 meters away fromthe place of refuelling).

– Never refuel in closed rooms. Fuel vaporsaccumulateat ground lever(risk of

explosions).

– Only transport and store fuel in approved containers. Makesure the fuel

stored is not accessible to children.