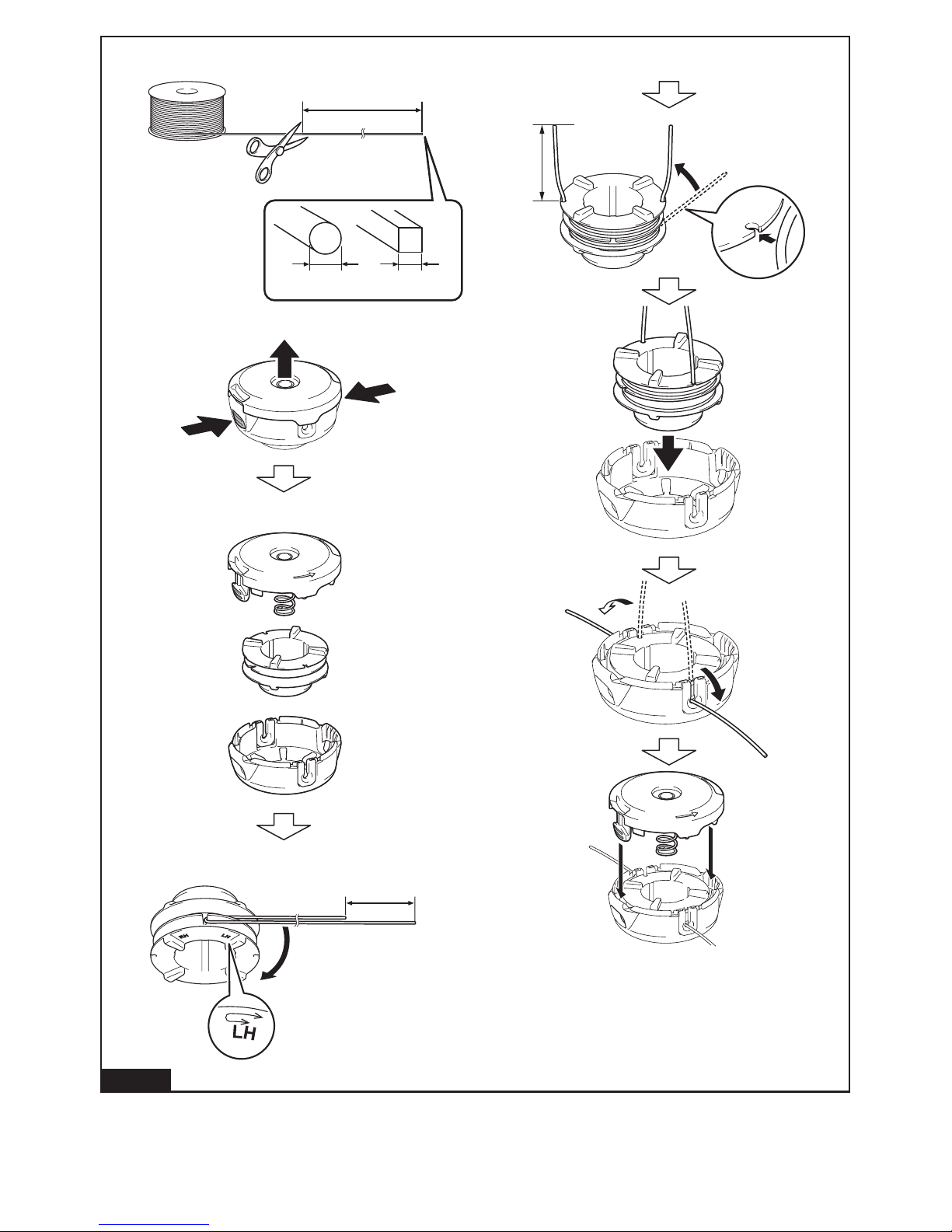

Makita EM404MP User guide

Other Makita Trimmer manuals

Makita

Makita EH5000W User manual

Makita

Makita XHU02 User manual

Makita

Makita UH3000D User manual

Makita

Makita UH004G User manual

Makita

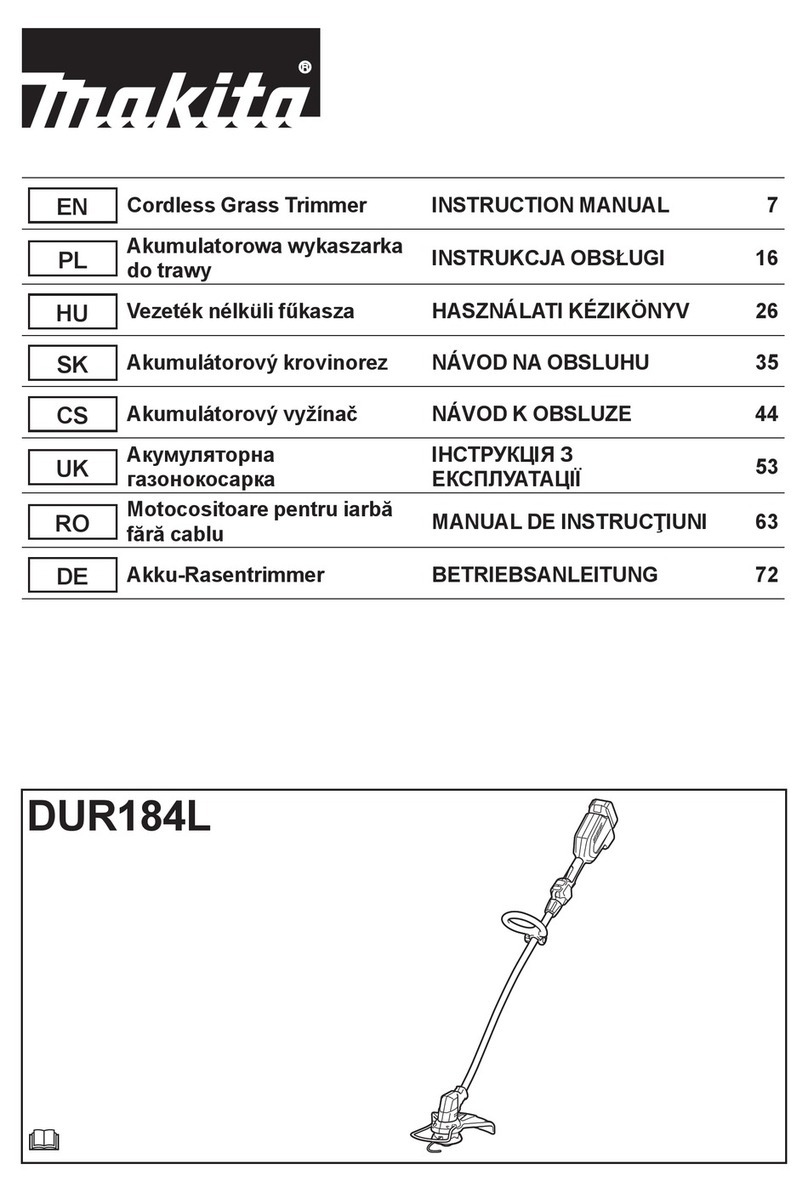

Makita DUR184L User manual

Makita

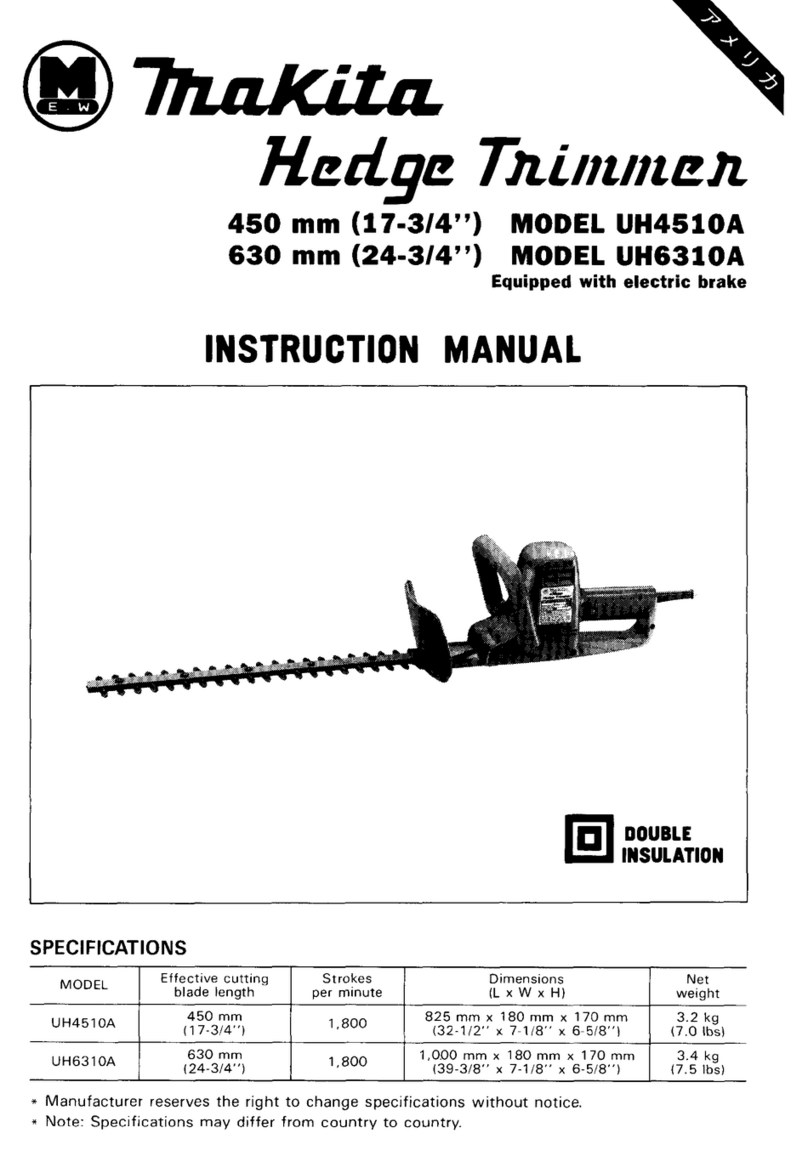

Makita UH4510A User manual

Makita

Makita BUR141 User manual

Makita

Makita EM2510LH User manual

Makita

Makita UH480D User manual

Makita

Makita DUR366L User manual

Makita

Makita DUR190U User manual

Makita

Makita EH760 User manual

Makita

Makita DUR190U User manual

Makita

Makita M372 User manual

Makita

Makita UR202C User manual

Makita

Makita EN400MP User guide

Makita

Makita UR012G User manual

Makita

Makita UR002GD201 User manual

Makita

Makita DUR189Z1 User manual

Makita

Makita RBC420 User guide