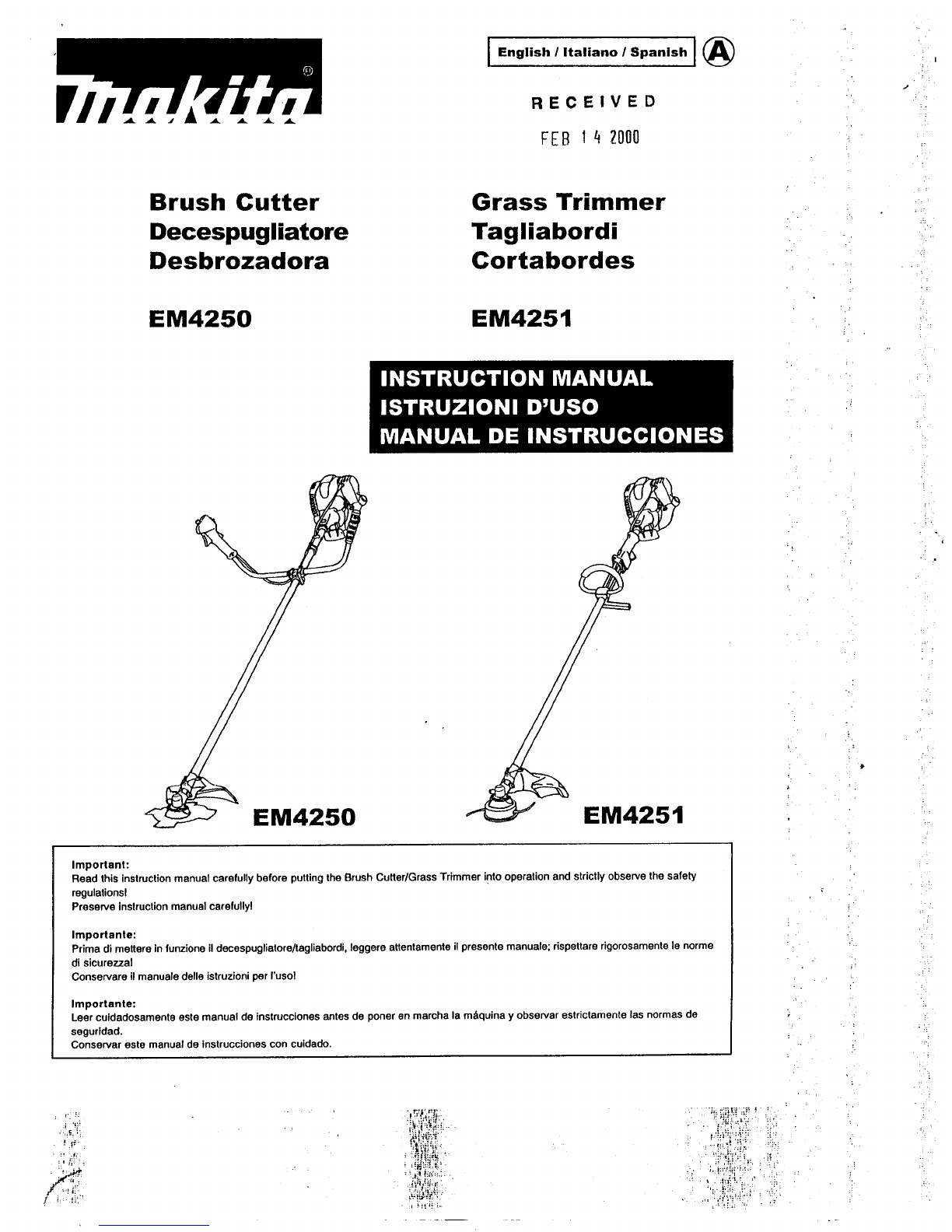

Start the BrushCutter/Grass trimmer only in accordancewith the instructions.

-Use

the BrushCuWGrass trimmer and the tools only for such applications

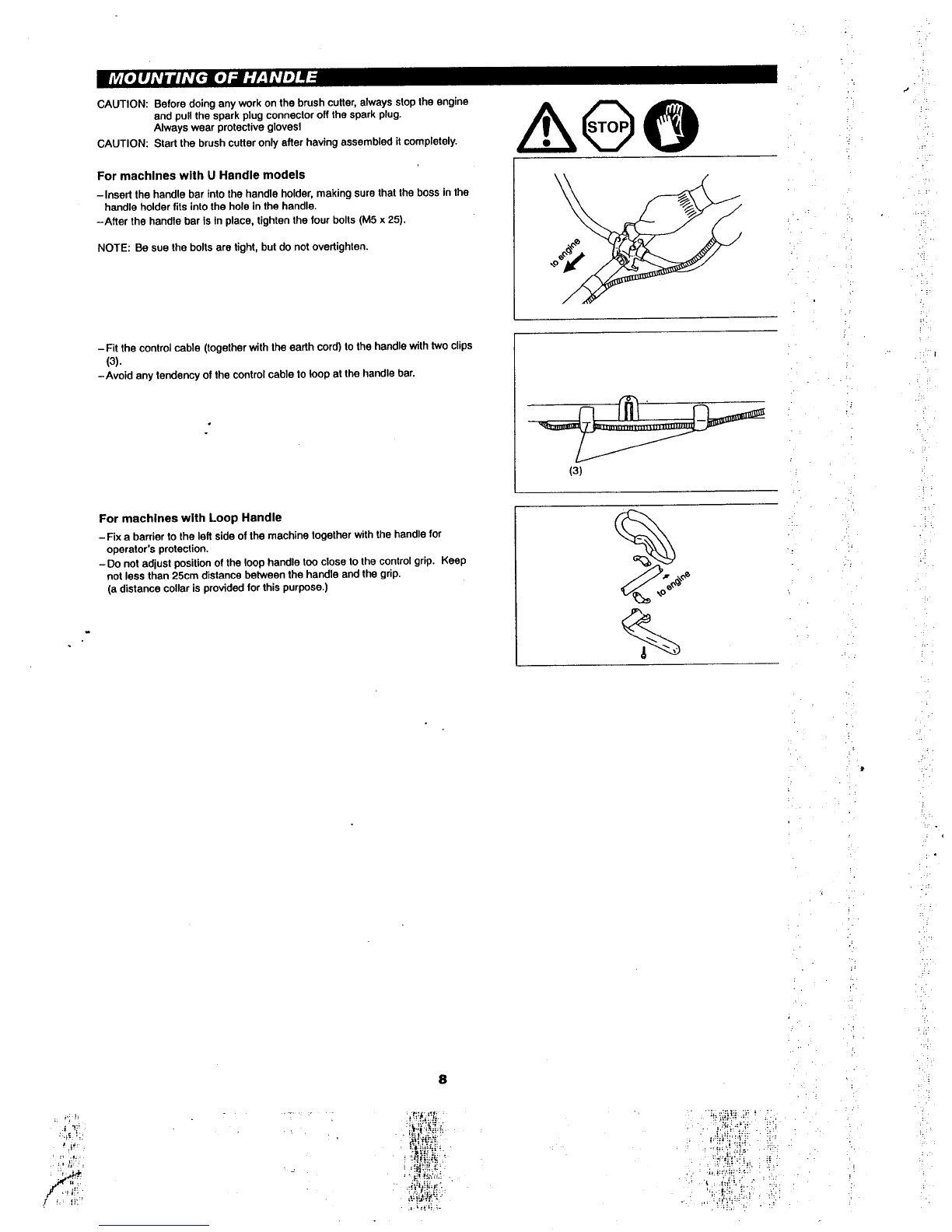

-Only start the BrushCutterlGrasstrimmer engine, aHer the entireassembly is

Do not useany other methodsfor startingthe engine1

as specified.

done. Operationof the device

Is

onlypermittedafter all the appropriate

accessories areattached1

-Before startingmakesure that the cutting tool has no contact with hard

objects such as branches, stones etc. as the cutting

tool

will revolvewhen

starting.

-The engine islobe switched

off

immediatelyincase of any engine problems.

-Should the cutting

tool

hitstones or other hardobjects, immediately switch

off

the engine and inspect the cuttingtool.

-Inspect the cuttingtool at short regular intervalsfor damage (detectionof

hairline cracks by meansof tapping-noisetest).

-Operate the BrushCuHer/Grasstrimmer only with the shoulder strap attached

which is

to

be suitably adjusted beforeputtingthe Brush CuttedGrasstrimmer

intooperation.

It

isessentialto adjust the shoulder strap according

to

the

user's size to prevent fatigue occurringduringuse. Never

hold

the cutterwith

one handduring use.

hands.

Always ensure a safe footing.

inhalationof the exhaust gases. Never runthe engine

in

enclosed rooms

(risk of gas poisoning). Carbon monoxide

Is

an odorless gas.

-Switch

off

the engine when restingandwhen leavingthe BrushCuttdGrass

trimmer unattended, andplace it ina safe locationto prevent danger to

others or damage

to

the machine.

-Never putthe hot BrushCuHer/Grasstrimmer onto dry grass or onto any

combustible materials.

-The cutting

tool

has

to

be equipped with it's appropriate guard.

Never runthe cutterwithout this guard1

-All protectiveinstallationsand guards suppliedwith the machine must be

usedduringoperalion.

-Never operate the engine with faultyexhaust muffler.

-Shut

off

the engine during transport.

-During transport over longdistancesthe toolprotectionincludedwith the

equipmentmust always be used.

-Ensure safe positionof the BrushCutter/Grass trimmer duringcar transporta-

tion

to

avoid fuel leakage.

-When transportingthe BrushCutter/Grass trimmer, ensure that the fueltank

iscompletely empty.

-When unloadingthe BrushCutter/Grasstrimmer from the truck, never drop

the Engine to the ground

or

this mayseverely damagethe fuel tank.

-vency,never drop or cast the BrushCuttedGrass

trimmer to the ground or this may severely damagethe BrushCutterlGrass

.-

trimmer.

-Remember

to

liftthe entire equipment from the groundwhen movingthe

equipment. Draggingthe fueltank ishighlydangerous and

will

cause

damage and leakage of fuel, possiblycausingfire.

-During operationalways holdthe BrushCuttedGrasstrimmer with both

-Operate the BrushCutter/Grass trimmer insuch a manner as

to

avoid

Refuelling

-Shut

off

the engine during refuelling,keepaway from open flames and do

not smoke.

-Avoid skincontactwith mineraloil products. Do not inhalefuel vapor.

Always wear protective gloves during refuelling. Change and clean

protectiveclothing at regular intervals.

-Take carenot

to

spill either fuelor oilinorder

to

prevent soil contamination

(environmental protection). Clean the BrushCutter/Grass trimmer Immedi-

ately after fuel hasbeenspilt.

-Avoid any fuel contact with your clothing. Changeyour clothinginstantly

if

fuel hasbeen spilt on

it

(to

prevent clothingcatchingfire).

-Inspect the fuelcap at regular intervalsmakingsurethat itcanbe securely

fastenedand does not leak.

-Carefully tightenthe fuel tank cap. Changelocationto start the engine (at

least

3

metersaway from the place of refuelling).

-Never refuelinclosedrooms. Fuelvapors accumulate at ground lever (risk of

explosions).

-Only transport and storefuel inapprovedcontainers. Makesure the fuel

stored is not accessible

to

children.

3

STOP

-

0

-

Resting

*

Transport

-

Refuelling

-

Maintenance

-

Tool Replacement

n

L

--

I