3

distance from work area.

• Make the workplace childproof making use of

padlocks, master keys or removing the ignition key.

• Do not force tool. It will perform the job better

and safer for the intended use.

• Use appropriate equipment. Do not wear loose

clothing, gloves, chains, rings, bracelets or other

accessories that could become caught in moving

parts.

• It is recommended wearing shoes with non-slip soles.

Use protection for the hair in order to hold them.

• Always wear safety glasses. Also use hearing

protection.

• Do not overreach on the equipment. Maintain

balance and feet in comfortable position at all times.

• Keep all tools in order. Keep tools sharp and clean for

better and safer performance. Follow the instructions

for lubricating and changing accessories.

better and safer performance. Follow the instructions

for lubricating and changing accessories.

• Unplug the machine before servicing or changing

accessories such as scissors, cutters etc.

• Reduce the risk of unintentional starting. Ensure

that the switch is in the “OFF” position (o) before

connecting the wire to the plug.

• Use recommended accessories. See the instruction

manual to check recommended accessories. Improper

use of accessories may cause risk of injury to persons.

• Never step on the machine. May occur serious

accident if the machine is dented or if parts are

accidentally touched.

• Check for damaged parts. Before continuing the use

of wood jointer, a guard or other part that is damaged

should be examined carefully to determine its proper

operation and perform its function properly. Check

the alignment of moving parts, breakage of parts,

mounting and any other condition that may aect

its operation. Any part that is damaged should be

repaired or replaced immediately. Do not use the tool

if the switch does not turn on or o.

• Never leave a running tool unattended. Turn o the

ignition key.

• The engine of this machine can emit sparks, and

explode flammable gases.

• Extension cables. Make sure your extension cord is

in good condition. When using an extension, be sure

of their ability to transmit the electrical current used

by your product. An undersized cord will cause drop

in voltage resulting in loss of power and overheating.

The following table shows the correct size to be used

depending on the cable diameter and amperage rate.

If in doubt, use a cable with a higher level of capacity.

IMPORTANT: Do not use an extension cord with length

above 20 meters.

Cable 2 wires Cable 3 wires

Ø (mm²) Amperage Ø (mm²) Amperage

0,5 90,5 8

1,0 13 1,0 12

1,5 16,5 1,5 15

2,5 23 2,5 20

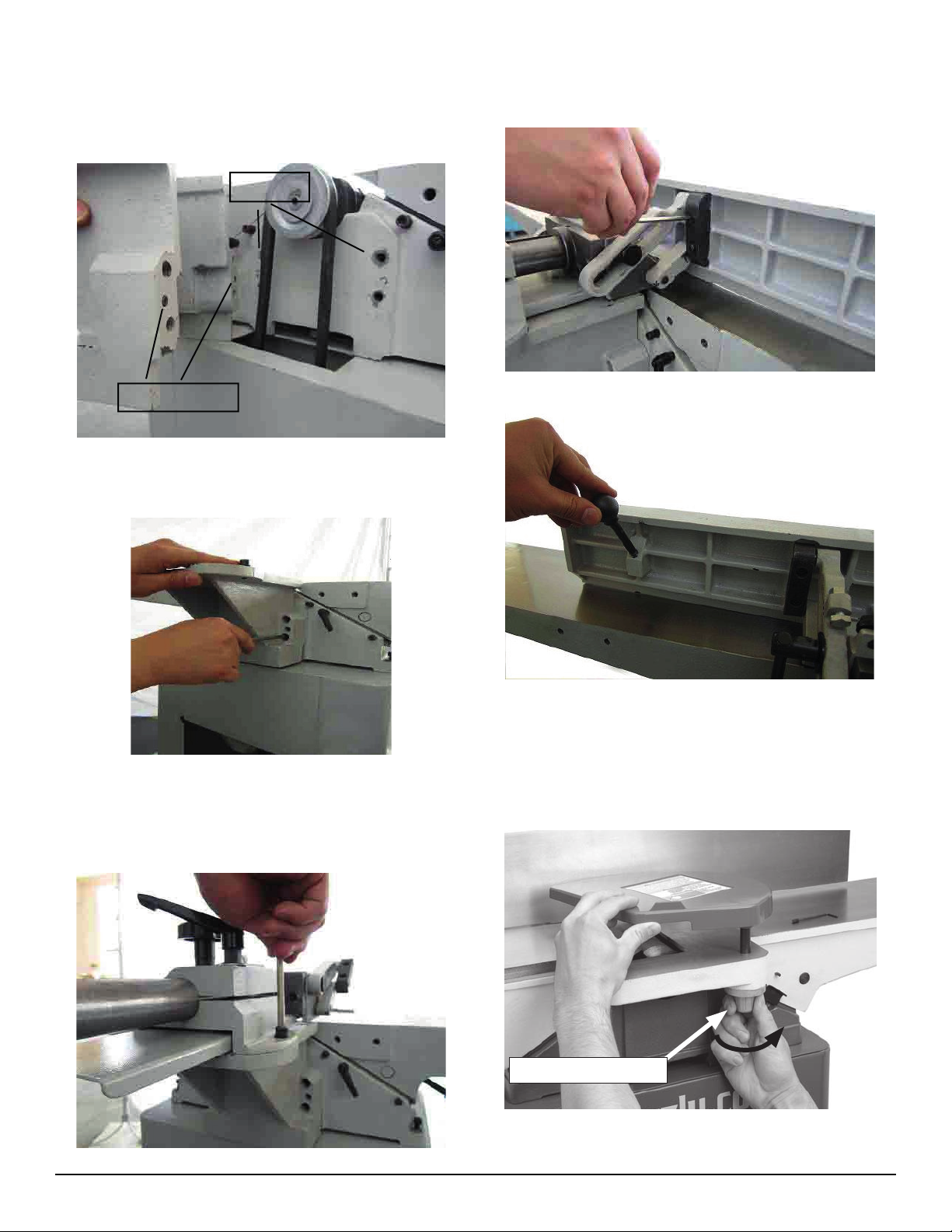

Additional safety rules for wood jointer:

CAUTION: FAILURE TO ATTEND THESE WARNINGS

MAY RESULT IN PERSONAL INJURY AND SERIOUS

DAMAGE TO THE MACHINE.

• Always use safety glasses. Also use face or dust mask

if cutting operation is dusty. Everyday eyeglasses only

have impact resistant lenses, they are NOT safety

glasses.

• Keep guards in place and working order.

• Protect the electric power supply line with at least a

20 amp fuse or a circuit breaker switch.

• Make sure that the advance is turning in the right

direction.

• Make sure that the knobs and screws are properly

tightened and safe before starting any operation.

• Keep sharp tools.

• Keep vents free of chips or dirt engines.

• Keep hands away from moving or sharp parts.

• Turn o the machine and unplug the power cord

before maintenance or adjustments of the tool.

• Support long pieces with a clamping device for

wood.

ALWAYS USE PROPER PROTECTIVE

EQUIPMENTS TO OPERATE THIS

MACHINE.