Mallory HYFIRE IV SERIES User manual

1

®

HYFIRE®IV SERIES OF ELECTRONIC

IGNITION CONTROLS

HYFIRE®IVCIgnition System Part No. 692, Universal

HYFIRE®IVAIgnition System Part No. 697, Universal

For applications triggered by points, Mallory Electronic Ignition Distributor (all models), original equipment electronic

ignition amplifiers and magnetic trigger pulses (magnetic pickup distributor or crank trigger ignition). Optional adapters

are available for easy connection to early model Delco/GM HEI Systems, late model GM HEI/EST Systems, Ford TFI

Systems, and OEM magnetic pickup (non-computer; Ford DuraSpark, GM HEI and Mopar/Chrysler Electronic Systems).

This product is legal to sell, distribute or install on vehicles in California. C.A.R.B. Executive Order D-70-26.

NOTE: Mallory HYFIRE®IV Electronic Ignition Controls are not compatible with distributorless systems or positive

ground applications. The RPM Limiter in the HYFIRE®IVC (Part No. 692) will not work properly with odd-fire or semi-

even fire V6 applications.

General Information ..............................................................................2

Ignition Ballast Resistor/Loom Resistance Wire ...........................2

Standard Ignition Bypass (Bypass Connector) .............................2

Ignition Coils ...................................................................................2

Fuel Injection ...................................................................................2

Spark Plug Wires.............................................................................2

Spark Plug Gaps .............................................................................2

Electric Welding ..............................................................................2

External RPM Limiters

Mallory PRO TACH®I, IV and VI ......................................................2

HYFIRE®IVC Ignition System 4 and 6 Cylinder Operation ...............2

Mounting Procedure .............................................................................2

Mounting to a Flat Surface Without Mounting Brackets ...............2

Mounting to a Flat or Uneven Surface

Using Mounting Brackets .........................................................2

Mounting to a Flat Surface with Shock Mounts .............................2

Wiring Procedure ..................................................................................3

Wiring Method using Adapters and Harnesses .............................3

GM HEI Systems/coil-in-cap with OEM module) .................. 3-4

Late Model GM HEI/EST Systems (external coil) ................. 3-5

Ford TFI Systems ........................................................................4, 6

Ford DuraSpark Systems (non-computer type,

without module) .................................................................... 5-6

Early Model GM HEI Systems (non-computer type,

without module) ....................................................................6, 8

Mopar/Chrysler Corp. Electronic Systems

(non-computer type, without module)..................................6, 9

Wiring Method Without Adapters .........................................................7

Breaker Point Systems ...............................................................7, 9

Mallory Electronic Ignition, UNILITE®Distributors,

Magnetic Breakerless Distributors or Electronic

Advance Distributors (3-wire/red, brown, green)...............7, 10

For OEM Electronic Systems with modules/amplifiers

(Chrysler, Ford, and import) ...............................................7, 10

Magnetic Pickup Trigger Pulses (magnetic

pickup distributors or crank trigger ignition) ..........................7, 10

RPM Limiter Operation HYFIRE®IVC Ignition System

(PN 692 only) .................................................................................11

Optional Ignition Accessories ............................................................11

Bypass Connector..............................................................................12

Mounting Template ............................................................................12

CONTENTS

Parts included in this kit:

1 HYFIRE®IV Electronic Ignition Control - Part No. 692 or 697

1 Ignition Control Harness - Part No. 29348

2 Terminal Connectors - Part No. 450

1 Bypass Connector

4 Cable Ties

2 Spade Terminals

8 Ring Terminals, 1/4"

1 Ring Terminal, 3/8"

5 Spade Receptacle Terminals

4 Mounting Brackets

4 #10 Sheet Metal Screws

INSTALLATION INSTRUCTIONS

FORM 1351 (REV. E) 10/99

2

GENERAL INFORMATION

The HYFIRE®IV Ignition System Part Nos. 692 and 697 are not for marine use.

The RPM limiter in the HYFIRE®IVC is not recommended as an engine speed governor. The

use of the RPM limiters is not recommended for applications equipped with a catalytic

converter. Similarly, forcing engine RPM past the RPM limiter continuously for long sustained

intervals can cause fuel build up in the exhaust system that may adversely affect your

application. The RPM limiting systems will not work properly with odd-fire V6 applications.

Ignition Ballast Resistor / Loom Resistance Wire

The performance of the HYFIRE®IV is not affected by the presence of the factory ignition

resistors or ignition ballast resistors in the wire from the ignition switch.

Standard Ignition Bypass (Bypass Connector)

The Bypass Connector (supplied) fits into the Ignition Control Harness to convert back to

standard ignition. If you use the Bypass Connector, use ignition ballast resistors designed for

your vehicles distributor and coil (see diagrams for more information). This bypass method

does not work with magnetic pickup distributor or crank trigger ignition. Racing Applications: It

is not necessary to install ignition ballast resistors. However, do not use the Bypass Connector

until the ignition ballast resistors are installed in the wire from the ignition switch.

Ignition Coils

The HYFIRE®IV Electronic Ignition Controls are designed to work with most original

equipment ignition coils. For optimum performance use the Mallory PROMASTER®Coil Part

No. 29440 (up to 7,500 RPM) or Part No. 29625 (up to 10,000 RPM).

Fuel Injection

Some fuel injection systems need a voltage spike signal from the ignition coil before it will

operate properly. This signal changes once HYFIRE®IV Electronic Ignition Controls are

installed. The Mallory Fuel Injection and Tachometer Adapters Part Nos. 29074 and 29078

supply the proper signal to the vehicle computer to operate the fuel injection system.

Installation procedure and diagrams are supplied with these adapters.

Spark Plug Wires

YOU MUST USE suppression type (carbon core, spiral core, suppression core) spark plug

wire. We recommend spiral core ignition wire, such as Mallory PRO SIDEWINDER®Ignition

Wire. Suppression type spark plug wires prevent false triggering and possible premature

ignition or accessory failures. DO NOT USE solid core (copper core; stainless steel core)

spark plug wire with any electronic ignition system or accessory.

Spark Plug Gaps

For street applications, use your engine manufacturer's specifications. For racing applications,

start with your engine manufacturer's specifications, then experiment with, and closely monitor,

various gaps to achieve maximum performance.

Electric Welding

Unplug the Ignition Control Harness from the HYFIRE®IV Electronic Ignition Control and

unplug any distributor harnesses (if possible) before any welding is done on the vehicle.

External RPM Limiters

Mallory Proportional RPM Limiter Part Nos. 641-4, 641-6, 641-8, 642, 643 and 644 WILL NOT

function with the HYFIRE®IV Electronic Ignition Controls.

Mallory PRO TACH®I, IV and VI

The RPM needle and shift light will work with the HYFIRE®IV. However, the tach's proportional

controller that limits RPM WILL NOT function with the HYFIRE®IV. Turn the LIMIT RPM knob

slightly past 11,000 to prevent the limiter from interfering with the tachs other functions. See

Optional Ignition Accessories for more information.

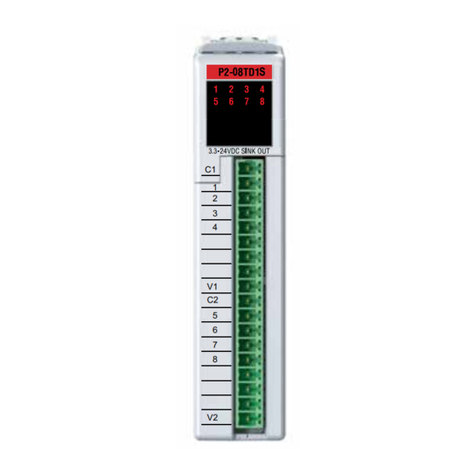

HYFIRE®IVC IGNITION SYSTEM

4 AND 6 CYLINDER OPERATION

The HYFIRE®IVC Ignition System comes from the factory set for 8 cylinder engines. 4 or 6

cylinder operations require you to set a switch inside the housing. DO THIS BEFORE

MOUNTING THE IGNITION BOX!

Use a T-15 Torx®tool to remove the four screws that holds the blank end panel to the

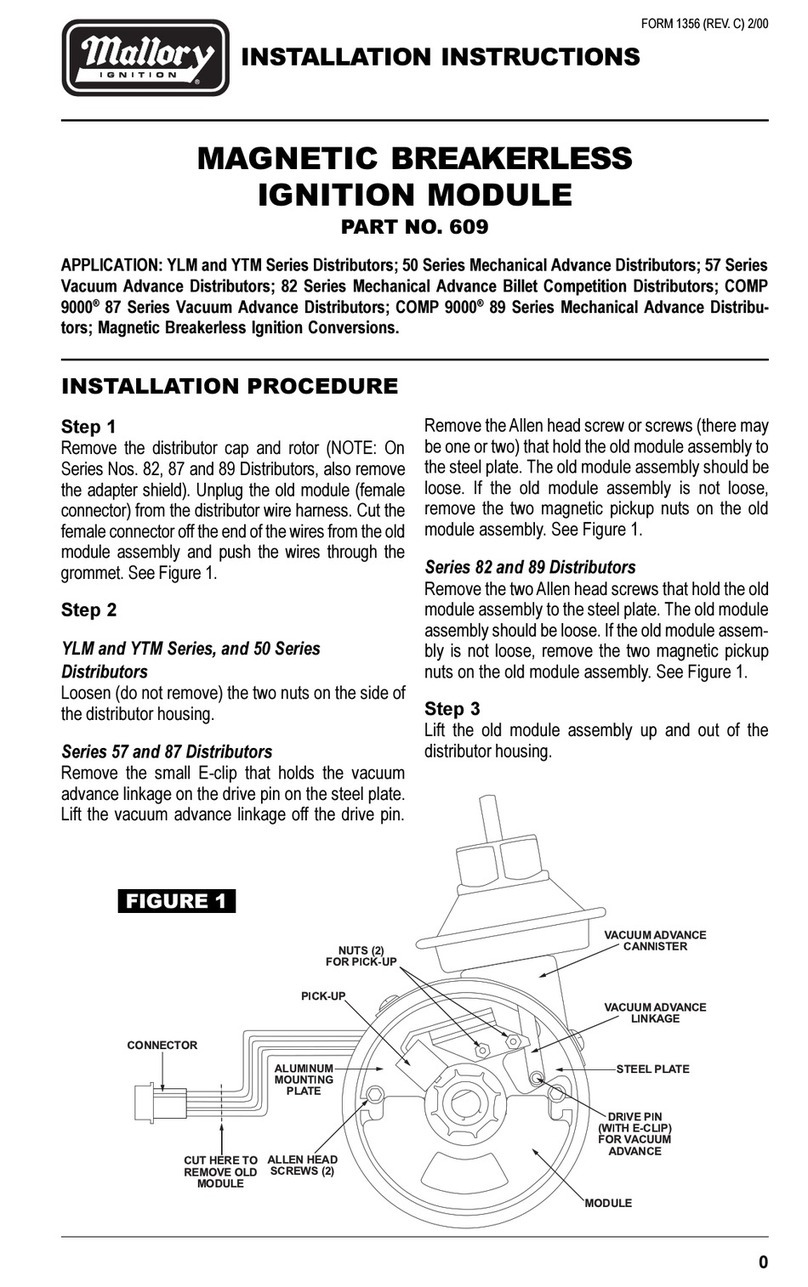

housing. Remove the blank end panel (see Figure 1).

With the ignition upside-down, look inside and on the left side of the PC board you will

see a small two position switch. The switch (#1) nearest the end of the PC board is the 6

cylinder switch. The other switch (#2) is the 4 cylinder switch. These switches are OFF

for 8 cylinder engines. Turn the appropriate switch ON for 4 or 6 cylinder operations.

Attach the blank end panel to the housing.

MOUNTING PROCEDURE

Step 1

Disconnect the battery () cable to cut power to the system. Computerized vehicles:

Disconnect the battery () cable and let the vehicle sit overnight before proceeding. This allows

the computer to calibrate for the new ignition.

Step 2

Select a convenient location to mount the HYFIRE®IV Electronic Ignition Control. Keep the

unit away from hot engine components or extreme heat such as the exhaust system and

manifolds. Also, keep it away from moving devices, such as fans, belts and linkages. The

location must be dry. Moisture will damage components inside the unit.

Step 3

Choose one mounting method listed below for mounting the HYFIRE®IV Electronic Ignition

Control (3a, 3b, or 3c).

(3a) Mounting to a flat surface without brackets

Center punch the mounting pattern on the mounting surface using the mounting

template to mark locations for drilling mounting holes. Drill holes using a 7/32" drill bit.

Hold the HYFIRE®IV Electronic Ignition Control in position over the mounting holes.

From the backside of the mounting surface, insert the 10-32 screws with lock washers

through the mounting holes and into the tapped holes in the bottom plate of HYFIRE®IV

Electronic Ignition Control. Tighten each screw until snug.

(3b) Mounting to a flat or uneven surface using brackets

Refer to Figure 2 while performing the following steps.

Position one hole of each bracket over each tapped hole in the bottom plate of the

HYFIRE®IV. Insert 10-32 screws with lock washers through these holes and into the

tapped hole in the bottom plate of the HYFIRE®IV. Tighten each screw until snug.

Hold the HYFIRE®IV in position where it will be mounted. Bend the brackets slightly to

meet uneven surfaces. Center punch the mounting pattern on the mounting surface to

mark locations for drilling mounting holes. Drill holes using a 9/64" drill bit.

Insert the #10 sheet metal screws through the remaining holes in the mounting brackets

and into the holes in the mounting surface. Tighten each screw until snug.

(3c) Mounting to a flat surface with shock mounts (available separately)

Center punch the mounting pattern on the mounting surface using the mounting

template to mark locations for drilling mounting holes. Drill holes using a 7/32" drill bit.

Install the shock mounts into the bottom plate of the HYFIRE®IV. Hold the unit in position

where it will be mounted.

From the backside of the mounting surface, insert the 10-32 nuts with lock washers onto

the shock mount studs. Tighten each nut until snug.

FIGURE 2

4 CYL

4 - 6 CYL

SWITCH

6 CYL

BOTTOM

OF

12

FIGURE 1

3

WIRING PROCEDURE

Step 1

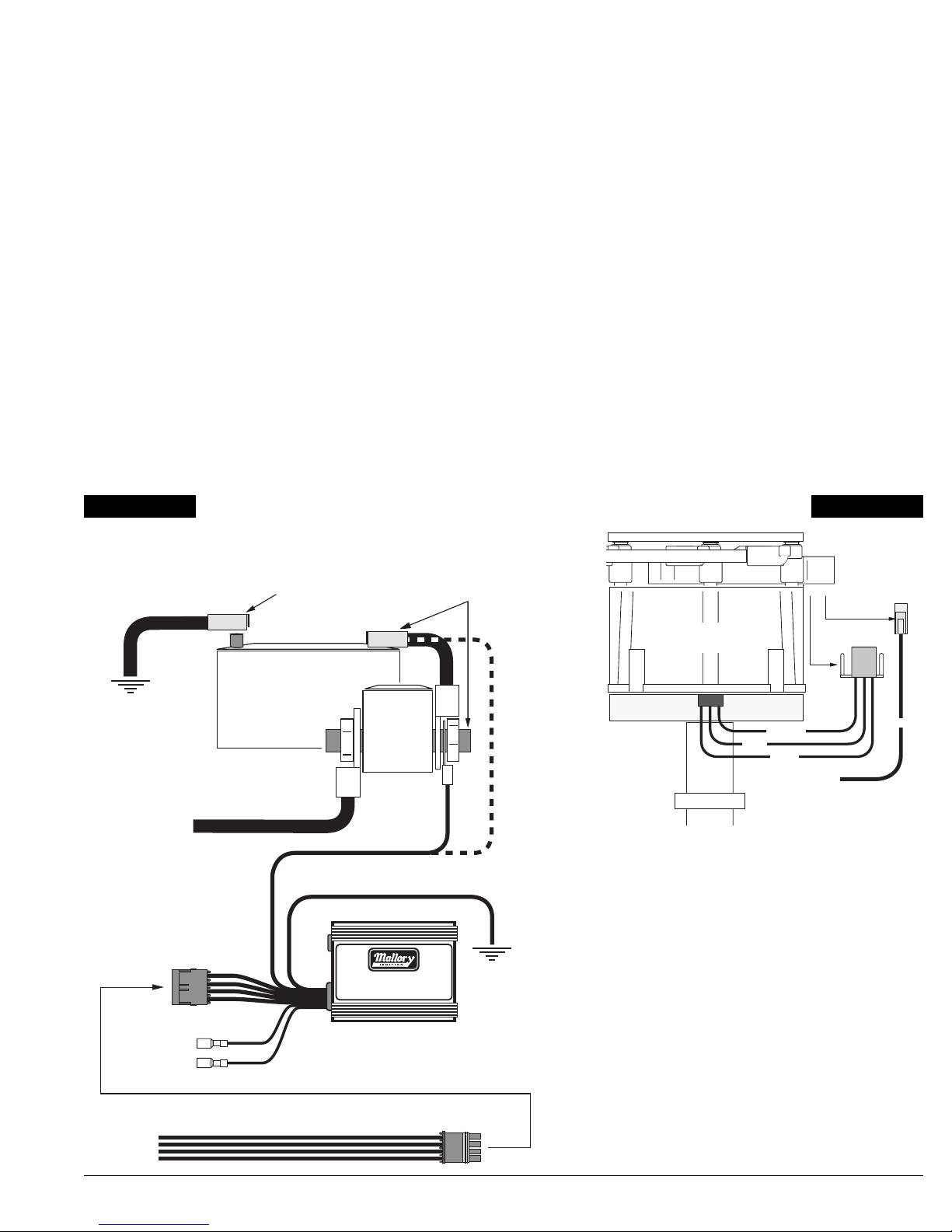

Refer to Figure 3

Ensure that your vehicle is equipped with a ground cable between the engine block and firewall

(10 gauge or larger is required). Locate one LONG RED WIRE and one LONG BLACK WIRE

at the end plate of the HYFIRE®IV Electronic Ignition Control.

Connect the LONG RED WIRE to the battery (+) post or battery (+) terminal on the

starter solenoid.

Connect the LONG BLACK WIRE to engine ground or chassis ground.

Connect the Ignition Control Harness to the Ignition Control Plug at the end plate of the

HYFIRE®IV Electronic Ignition Control.

Step 2

Choose one method listed below for wiring the HYFIRE®IV Electronic Ignition Control (2a, 2b,

or 2c)

(2a) Wiring method using Adapters and Harnesses (sold separately)

Special wiring Adapters and Harnesses simplify the installation of the HYFIRE®IV Electronic

Ignition Control into newer vehicles. These adapters and harnesses allow you to connect the

HYFIRE®IV Electronic Ignition Control between the ignition coil and the factory coil connector.

They reduce installation time and wiring errors. Also, converting back to the factory ignition is

easy because there is no need to cut the original wiring. These instructions cover:

PART NO. 29042 Connecting to GM HEI Systems (coil-in-cap, with OEM ignition module)

PART NO. 29068 Connecting to Late Model GM HEI/EST Systems (external coil)

PART NO. 29062 Connecting to Ford TFI Systems.

PART NOS. 29039 and 29040 Connecting to Ford DuraSpark Systems (non-computer

type, without ignition module).

PART NOS. 29040 and 29043 Connecting to Early Model GM HEI Systems (non-computer

type, without ignition module)

PART NO. 29040 Connecting to Mopar/Chrysler Electronic Systems (non-computer type,

without ignition module).

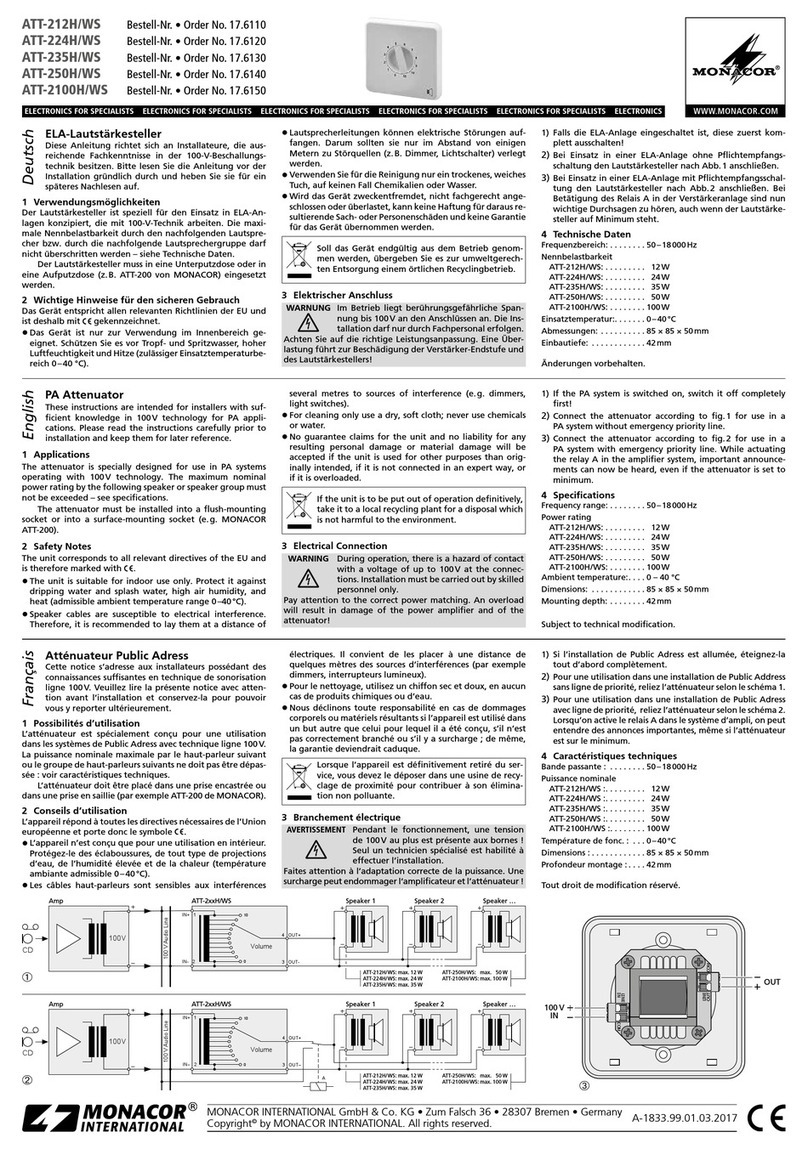

Connecting to: GM HEI Systems (coil-in-cap, with OEM ignition module), use Adapter

PART NO. 29042; Late Model GM HEI/EST Systems, use Adapter PART NO. 29068; Ford

TFI Systems, use Adapter PART NO. 29062.

Connecting Adapter PART NO. 29042, 29062 or 29068

Refer to Figures 4, 5, and 8 when connecting to GM HEI Systems; Figure 6 when connecting

to Late Model GM HEI/EST Systems; Figure 7 when connecting to Ford TFI Systems.

Match wires by color from the Adapter to the Ignition Control Harness. Crimp all wires

together.

Disconnect the factory harness(es) at the ignition coil. Connect them to the Adapter that has

the RED and GREEN WIRES.

Connect the Adapter that has the YELLOW and BLACK WIRES to the ignition coil. NOTE:

When using an aftermarket ignition coil with post type terminals, discard the Adapter that has

the YELLOW and BLACK WIRES. Install ring terminals on the Ignition Control Harness

YELLOW and BLACK WIRES. Connect the YELLOW WIRE to the ignition coil (+) terminal.

DO NOT allow any wire except the YELLOW WIRE to make contact with the ignition coil (+)

terminal. Connect the BLACK WIRE to the ignition coil () terminal.

Go to Step 3, page 9.

(DISCONNECT)

GM/DELCO HEI DISTRIBUTOR

WITH COIL MOUNTED INSIDE

DISTRIBUTOR CAP

MALLORY 8MM SUPPRE

BAT

PLUG

DISTRIBUTOR

PLUG

PINK OR RED

BLACK

BROWN

PINK OR RED

TOVEHICLE HARNESS

(12VOLT/IGNITION SWITCH)

FIGURE 4

IGNITION CONTROL HARNESS

DISCONNECT UNTIL INSTALLATION IS COMPLETE

ENGINE OR CHASSIS

GROUND

TOTHE STARTER

RED

GREEN

BLACK

YELLOW

(–) 12V/BATTERY (+)

ENGINE OR

CHASSIS

GROUND

CONNECT REDWIRE

AT EITHER LOCATION

IGNITION CONTROL

PLUG

LONG REDWIRE

LONG BLACKWIRE

SMALL GREEN AND BLACK

WIRES – NOT USED

HYFIRE

®

IGNITION

SYSTEM

®

STARTER

SOLENOID

(TYPICAL)

FIGURE 3

4

GM HEI/EST DISTRIBUTOR - EXTERNAL

IGNITION COIL

AND ADAPTER / HARNESS PART NO. 29068

ABCD

IGNITION CONTROL HARNESS

ADAPTER /HARNESS

PART NO. 29068

TOTHE

IGNITION

COIL

BOTH OFTHE

FACTORY

HARNESS

PLUGS

(ORIGINALLY

CONNECTED

TOTHE COIL)

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

YELLOW

BLACK

GREEN

RED

YELLOW

BLACK

GREEN

RED

RED AND GREEN

YELLOW AND BLACK

NOTE:

YELLOW/COIL (+)

BLACK/COIL (–)

SMALL GREEN AND BLACK

WIRES – NOT USED

FIGURE 6

GM/DELCO HEI DISTRIBUTOR

(WITH COIL MOUNTED INSIDE DISTRIBUTOR CAP)

ADAPTER / HARNESS

PART NO. 29042

ABCD

PINK OR RED

GM/DELCO HEI DISTRIBUTOR

WITH COIL MOUNTED INSIDE

DISTRIBUTOR CAP

MALLORY 8MM SUPPRE

DISTRIBUTOR

PLUG

NOTE:LEAVETACH PLUG, IFTHERE IS ONE,

PLUGGED INTOTHE DISTRIBUTOR CAP

ADAPTER / HARNESS

PART NO. 29042

GREEN

RED

BAT

PLUG

BLACK

TO ENGINE

GROUND

BROWN

YELLOW IGNITION CONTROL

HARNESS

NOTE:MOST AFTERMARKET REPLACEMENT IGNITION MODULESWILL NOT

TRIGGERTHE HYFIRE

®

IGNITION SYSTEM.THE BEST TYPE TO USE IS AN

ORIGINAL GM/DELCO IGNITION MODULE.

TOVEHICLE HARNESS

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

SMALL GREEN AND BLACK

WIRES – NOT USED

HYFIRE®IGNITION

SYSTEM

®

FIGURE 5

FORDTFI SYSTEMS

ADAPTER / HARNESS

PART NO. 29062

ABCD

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

YELLOW

BLACK

GREEN

RED

YELLOW

BLACK

GREEN

RED

NOTE:

YELLOW/COIL (+)

BLACK/COIL (–)

ADAPTER /HARNESS

PART NO. 29062

TOTHE

IGNITION

COIL

YELLOW

GREEN

RED

BLACK

FACTORY

HARNESS

PLUG

(ORIGINALLY

CONNECTED

TOTHE COIL)

SMALL GREEN AND BLACK

WIRES – NOT USED

IGNITION CONTROL HARNESS

FIGURE 7

5

SMALL RED / MAG + SMALL GREEN

SPADE TERMINAL CONNECTORS

SMALL BLACK

SMALL BLACK / MAG –

ADAPTER PART NO. 29040

NOT USED

YELLOW

ORANGE

ADAPTER PART NO.

29039; 2 OF 2

DISTRIBUTOR PLUG

PUSH CONNECTORS ONTO

PINS AS FAR AS POSSIBLE

IGNITION

CONTROL

HARNESS

RED

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

®

HYFIRE

®

IGNITION

SYSTEM

®

ADAPTER PART NO. 29039;1 OF 2

FEMALE SOCKET

IGNITION COIL

TO MATCHING

MALE SOCKET ON

THEVEHICLE

SPADE

RECEPTACLE

TERMINALS

BLACK

YELLOW

GREEN

(NOT USED)

FORD AND AMERICAN MOTORS

MOTORCRAFT DURASPARK (SSI, I AND II),

MALLORY 85 SERIES DISTRIBUTOR ADAPTER

PART NOS. 29039 AND 29040

+–

FIGURE 9

+

-

MALLORY

PROMASTER®

COIL

Part No. XXXXX

MALLORY 8MM SUPPRE

GM/DELCO HEI DISTRIBUTOR

(WITH REMOTE COIL ADAPTER)

ADAPTER / HARNESS

PART NO. 29042

.

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

SMALL GREEN AND BLACK

WIRES – NOT USED

NOTE:DO NOT USE IGNITION

BALLAST RESISTORS SUPPLIED

WITH PROMASTER® COILS OR

OTHER AFTERMARKET COILS.

TACHOMETER / RPM SENSING LEAD:

CONNECTTHE TACH LEAD TOTHE

COIL (–)TERMINAL.

IGNITION CONTROL HARNESS

YELLOW

BLACK

GREEN RED

GREEN

RED

DISTRIBUTOR

PLUG

BAT

PLUG

PINK

OR

RED

ADAPTER / HARNESS PART NO. 29042

WITH GREEN AND REDWIRES

NOTE:DISCARD ADAPTER / HARNESS PART NO. 29042

WITHYELLOW, BROWN AND BLACK WIRES. MOST

AFTERMARKET REPLACEMENT IGNITION MODULES

WILL NOTTRIGGERTHE HYFIRE® IGNITION SYSTEM.

THE BESTTYPE TO USE IS AN ORIGINAL GM/DELCO

IGNITION MODULE.

GM/DELCO HEI DISTRIBUTOR

WITH MALLORY HEI REMOTE COIL

ADAPTER INSTALLED

TOVEHICLE

HARNESS

FIGURE 8

6

Connecting to Ford DuraSpark Systems (non-computer type) using Adapter PART

NO. 29039 and Harness PART NO. 29040 for OEM magnetic pickup

Refer to Figure 9 while performing the following steps.

Connecting Adapter PART NO. 29039:

Disconnect all connectors at the ignition module, ignition coil and distributor. Remove the

ignition module. Remove the distributor and coil harnesses.

Connect the Adapter ORANGE WIRE to the distributor plugs ORANGE WIRE.

Connect the Adapter YELLOW WIRE to the distributor plugs PURPLE WIRE.

Connect the other Adapter female socket to the vehicles matching male socket. (The

matching male socket was originally connected the ignition module.)

Connecting the Harness PART NO. 29040:

Connect the HYFIRE®IV Electronic Ignition Controls SMALL GREEN WIRE to the

Harness RED WIRE.

Connect the HYFIRE®IV Electronic Ignition Controls SMALL BLACK WIRE to the

Harness BLACK WIRE.

Connect the mating plug of the Harness to the mating plug of the Adapter Part No. 29039

from the distributor.

Connecting the Ignition Control Harness:

Route the Ignition Control Harness to the coil so that its wires do not make contact with

extreme heat, sharp objects or moving devises such as fans, belts and linkages.

Crimp the Ignition Control Harness RED WIRE to the slice connector on the Adapter Part

No. 29039 female socket.

Crimp a spade receptacle terminal on the Ignition Control Harness YELLOW WIRE.

Connect the YELLOW WIRE to the ignition coil (+) terminal. DO NOT allow any wire

except the YELLOW WIRE to make contact with the coil (+) terminal.

Crimp a spade receptacle terminal on the Ignition Control Harness BLACK WIRE.

Connect the BLACK WIRE to the ignition coil () terminal.

NOTE: Do not connect the GREEN WIRE of the Ignition Control Harness to anything.

Tape the end of the wire to insulate it.

Go to Step 3, page 9.

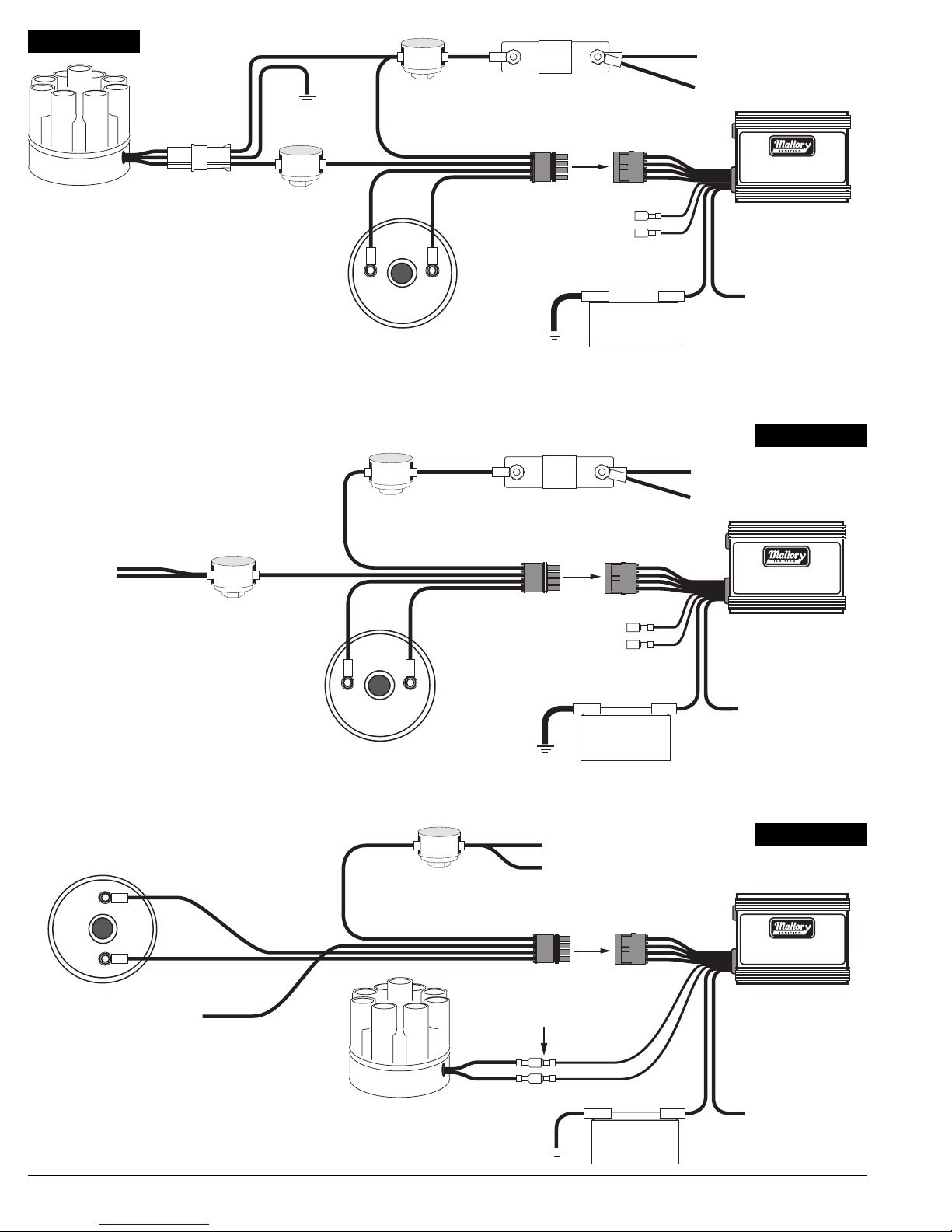

Connecting to Early Model GM HEI Systems (non-computer type) using Adapter

PART NO. 29043 and Harness PART NO. 29040 for OEM magnetic pick-up. Refer to

Figures 11 and 12 while performing the following steps.

Connecting Adapter PART NO. 29043:

For coil-in-cap distributors only

Disconnect the (RED or PINK) BAT PLUG/wire from the distributor cap.

Disconnect the tachometer wire from the TACH terminal on the distributor cap.

Disconnect the distributor plug from the distributor cap. For coil-in-cap distributors and

external coil

Remove the distributor cap.

Disconnect the pickup plug from the ignition module.

Remove the ignition module, radio noise filter/capacitor and distributor plug harness.

Slide the Adapter ORANGE and YELLOW WIRES through the grommet (supplied).

Connect the Adapter ORANGE WIRE to the pickup plugs WHITE WIRE.

Connect the Adapter YELLOW WIRE to the pickup plugs GREEN WIRE.

Position the grommet into the slot on the edge of the distributor housing. Use cable ties

and 8-32 screws to hold wires in place.

Install the distributor cap.

Connecting the Harness PART NO. 29040:

Connect the HYFIRE®IV Electronic Ignition Controls SMALL GREEN WIRE to the

Harness RED WIRE.

Connect the HYFIRE®IV Electronic Ignition Controls SMALL BLACK WIRE to the

Harness BLACK WIRE.

Connect the mating plug of the Harness to the mating plug of the Adapter Part No. 29043

from the distributor.

Connecting the Ignition Control Harness:

Route the Ignition Control Harness to the coil so that its wires do not make contact with

extreme heat, sharp objects or moving devises such as fans, belts and linkages.

Crimp a spade terminal on the Ignition Control Harness RED WIRE.

For coil-in-cap distributors only

Refer to Figure 11 while performing the following steps.

Connect the BAT PLUG/wire to the RED WIRE.

Crimp the YELLOW WIRE to the YELLOW WIRE of the Adapter Part No. 29043 3-pin

connector.

Crimp the BLACK WIRE to the BROWN WIRE of the Adapter Part No. 29043 3-pin

connector.

Plug the Adapter Part No. 29043 3-pin connector into the distributor cap.

Note: DO NOT connect the GREEN WIRE of the Ignition Control Harness to anything.

Tape the end of it to insulate it.

Go to Step 3, page 9.

For external coil only

Refer to Figure 12 while performing the following steps.

(Replace the words spade receptacle terminal with ring terminal when after-

market coils with post type terminals are used.)

Disconnect the BAT wire from the ignition coil BAT/(+) terminal. Connect the BAT wire to

the RED WIRE.

Disconnect the tachometer wire from the ignition coil TACH/() terminal.

Crimp a spade receptacle terminal on the Ignition Control Harness YELLOW WIRE.

Connect the YELLOW WIRE to the ignition coil BAT/(+) terminal. DO NOT allow any wire

except the YELLOW WIRE to make contact with the ignition coil BAT/(+) terminal.

Crimp a spade receptacle terminal on the Ignition Control Harness BLACK WIRE.

Connect the BLACK WIRE to the ignition coil BAT/() terminal.

Discard the adapter plug with the yellow and brown wires from the Adapter PART NO.

29043. It is not used on external ignition coil HEI systems.

Note: DO NOT connect the GREEN WIRE of the Ignition Control Harness to

anything. Tape the end of it to insulate it.

Go to Step 3, page 9.

Connecting to Mopar/Chrysler Electronic Systems (non-computer type) using

Harness PART NO. 29040 for OEM magnetic pickup

Refer to Figure 13 while performing the following steps.

Disconnect all connectors at the ignition module, ignition coil and distributor. Remove the

ignition module. Take notice of a DARK GREEN/RED WIRE connected to the ignition

ballast resistor. Remove the distributor and coil harnesses.

Connecting the Harness PART NO. 29040:

Connect the HYFIRE®IV Electronic Ignition Controls SMALL GREEN WIRE to the

Harness RED WIRE.

Connect the HYFIRE®IV Electronic Ignition Controls SMALL BLACK WIRE to the

Harness BLACK WIRE.

Connect the mating plug of the Harness to the distributor plug.

Connecting the Ignition Control Harness:

Route the Ignition Control Harness to the ignition coil so that its wires do not make

contact with extreme heat, sharp objects or moving devices such as fans, belts and

linkages.

Connect the RED WIRE to the terminal on the ignition ballast resistor that previously had

the DARK GREEN/RED WIRE connected to it (or to a 12-volt wire from the ignition

switch). NOTE: The RED WIRE must get voltage when the ignition switch is in the

START and RUN positions.

Connect the YELLOW WIRE to the ignition coil (+) terminal. DO NOT allow any wire

except the YELLOW WIRE to make contact with the ignition coil (+) terminal.

Connect the BLACK WIRE to the ignition coil () terminal.

DO NOT connect the GREEN WIRE of the Ignition Control Harness to anything. Tape

the end of it to insulate it.

Go to Step 3, page 9.

7

MAGNETIC PICKUP/CRANK TRIGGER COLOR CODES

BRAND/TYPE MAG+ MAG

MALLORY CRANK TRIGGER PURPLE GREEN

MALLORY BILLET COMPETITION DISTRIBUTOR,

SERIES NOS. 81 AND 84 ORANGE PURPLE

MALLORY COMP 9000®SERIES NOS 96-99 ORANGE PURPLE

MALLORY HARNESS PART NO. 29040 RED BLACK

MSD CRANK TRIGGER PURPLE GREEN

MSD CRANK TRIGGER (OLD STYLE) ORANGE BLACK

MSD DISTRIBUTOR ORANGE PURPLE

MOROSO CRANK TRIGGER BLACK WHITE

ACCEL®CRANK TRIGGER BLACK WHITE

CHRYSLER ELECTRONIC DISTRIBUTOR ORANGE BLACK

FORD DURASPARK DISTRIBUTOR ORANGE PURPLE

DELCO/GM HEI DISTRIBUTOR WHITE GREEN

2BWiring method without adapters; all breaker point distributors;

Mallory Electronic Ignitions (three wire/red, brown, green); OEM

electronic ignition amplifiers.

Refer to: Figure 14 for breaker point distributors; Figure 16 for Mallory UNILITE®

Distributors, Magnetic Breakerless Distributors or Electronic Advance Distributors

(three wire/red, brown, green); Figure 17 for OEM electronic ignition amplifiers

Connecting the Ignition Control Harness

Route the Ignition Control Harness to the ignition coil so that its wires do not make contact with

extreme heat, sharp objects or moving devises such as fans, belts and linkages.

Disconnect ALL wires located on the ignition coil (+) terminal. These include the wires from the

ignition switch/ignition ballast resistor, start/ignition bypass and any other wires normally

connected to the ignition coil (+) terminal. Connect these wires to the RED WIRE. NOTE: The

RED WIRE must get voltage when the ignition switch is in the START and RUN positions. If

you are using a Mallory Electronic Ignition, connect its BROWN WIRE to engine ground and

add its RED WIRE to the Ignition Control Harness RED WIRE. Use Ring Terminal Connectors

to join wires together (See page 2 - Ignition Ballast Resistor / Loom Resistance Wire and

Standard Ignition Bypass).

Similarly, disconnect ALL wires located on the ignition coil () terminal. Connect these wires to

the GREEN WIRE. If you are using a Mallory Electronic Ignition, add its GREEN WIRE to the

Ignition Control Harness GREEN WIRE. Use Ring Terminal Connectors to join wires together.

Connect the YELLOW WIRE to the ignition coil (+) terminal. DO NOT allow any wire except

the YELLOW WIRE to make contact with the ignition coil (+) terminal.

Connect the BLACK WIRE to the ignition coil () terminal.

Go to Step 3, page 9.

RING TERMINAL CONNECTORS:

Furnished with the HYFIRE®IV Electronic Ignition Controls are two Ring Terminal Connectors

for the convenience of getting a neat installation when the HYFIRE®IV Electronic Ignition

Control is added to an existing ignition system. These Ring Terminal Connectors allow the

existing ignition system wiring to remain in the area of the ignition coil.

Move wires onto the stud that is inside the Ring Terminal Connector body.

Secure these wires to the stud with the nut and washer.

Install the Ring Terminal Connector cap.

2CWiring Method without adapters for Magnetic Pickup Trigger

Pulses (Non-Computer Type); Magnetic Pickup Distributors or

Crank Trigger Ignition

Connecting to Magnetic Pickup Distributors and Crank Trigger Ignition Refer to

Figure 18.

Connect the magnetic pickup (+) wire to the SMALL GREEN WIRE from the HYFIRE®IV

Electronic Ignition Control.

Connect the magnetic pickup () wire to the SMALL BLACK WIRE from the HYFIRE®IV

Electronic Ignition Control.

Connecting the Ignition Control Harness:

Route the Ignition Control Harness to the ignition coil so that its wires do not make

contact with extreme heat, sharp objects or moving devises such as fans, belts and

linkages.

Connect the RED WIRE to the 12-volt wire from the ignition switch. NOTE: The RED

WIRE must get voltage when the ignition switch is in the START and RUN positions. Use

a Ring Terminal Connector to join wires together.

Connect the YELLOW WIRE to the ignition coil (+) terminal. DO NOT allow any wire

except the YELLOW WIRE to make contact with the ignition coil (+) terminal.

Connect the BLACK WIRE to the ignition coil () terminal.

DO NOT connect the GREEN WIRE of the Ignition Control Harness to anything. Tape

the end of it to insulate it.

Go to Step 3, Page 9.

FIGURE 10

8

MALLORY 8MM SUPPRE

GM/DELCO HEI DISTRIBUTOR

(WITH COIL MOUNTED INSIDE DISTRIBUTOR CAP)

ADAPTER / HARNESS

PART NOS. 29040 AND 29043

GM/DELCO HEI DISTRIBUTOR

(WITH REMOTE COIL ADAPTER)

ADAPTER / HARNESS

PART NOS. 29040 AND 29043

+

-

MALLORY

PROMASTER®

COIL

Part No. XXXXX

MALLORY 8MM SUPPRE

ABCD

ORANGE

GREEN

WHITE

PICKUP PLUG

CABLETIE

YELLOW

CABLETIE

IGNITION

CONTROL

PLUG

IGNITION

CONTROL

HARNESS

LONG BLACK

(–) BATTERY (+)

LONG RED

SMALL RED / MAG +

PINK OR RED

NOTE: LEAVETACH PLUG, IFTHERE IS ONE,

PLUGGED INTOTHE DISTRIBUTOR CAP

YELLOW

BLACKBROWN

TOVEHICLE

HARNESS

SMALL

GREEN

SMALL

BLACK

SMALL BLACK / MAG –

SMALL RED / MAG +

ADAPTER / HARNESS

PART NO. 29040

SMALL

GREEN

SMALL

BLACK

YELLOW

GREEN NOT USED

BLACK

SMALL BLACK / MAG –

RED

BAT

PLUG

GREEN

NOT USED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

IGNITION

CONTROL

PLUG

IGNITION

CONTROL

HARNESS

LONG BLACK

(–) BATTERY (+)

LONG RED

TOVEHICLE

HARNESS

GM/DELCO HEI DISTRIBUTOR

WITH MALLORY HEI REMOTE

COIL ADAPTER INSTALLED BAT

PLUG

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

NOTE:DO NOT USE IGNITION BALLAST

RESISTORS SUPPLIEDWITH

PROMASTER® COILS OR OTHER

AFTERMARKET COILS.

TACHOMETER / RPM SENSING LEAD:

CONNECTTHE TACH LEADTOTHE

COIL (–)TERMINAL.

HYFIRE

®

IGNITION

SYSTEM

®

ADAPTER / HARNESS

PART NO. 29040

ADAPTER / HARNESS

PART NO.29043; 2 OF 2

ADAPTER / HARNESS

PART NO.29043; 1 OF 2

GM/DELCO HEI DISTRIBUTOR

WITH COIL MOUNTED INSIDE

DISTRIBUTOR CAP

MAGNETIC

PICK-UPWIRES

NOTE:DISCARD ADAPTER / HARNESS PART

NO.29043 WITHYELLOW AND BROWN WIRES.

SPADE RECEPTACLE TERMINALS

SPADE RECEPTACLE TERMINALS

FIGURE 11

FIGURE 12

9

IGNITION

CONTROL

PLUG

IGNITION

CONTROL

HARNESS

LONG BLACK

(–) BATTERY (+)

LONG RED

SMALL

BLACK

SPADETERMINAL

CONNECTORS

SMALL

GREEN

GREEN (NOT USED) RED

BLACK

YELLOW

IGNITION COIL

SMALL BLACK / MAG –

SMALL RED / MAG +

ALLWIRES NORMALLY CONNECTED

TOTHE COIL (+)TERMINAL

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

MOPAR / CHRYSLER

ADAPTER PART NO. 29040

ADAPTER PART NO. 29040

+

–

FIGURE 13

IGNITION COIL

GREEN

BLACK YELLOW

IGNITION CONTROL

HARNESS

OEM BALLAST OR

MALLORY BALLAST

RESISTOR (PN. 700)

NOTE:DO NOT DISCONNECT CONDENSOR

+12VOLTS FROM IGNITION SWITCH

ALL OTHERWIRES ORIGINALLY

CONNECTEDTOTHE COIL (+)TERMINAL

RINGTERMINAL

CONNECTOR

RINGTERMINAL

CONNECTOR

BREAKER POINT DISTRIBUTOR

RED

+–

IGNITION

CONTROL

PLUG

LONG BLACK

(–) BATTERY (+)

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

HYFIRE

®

IGNITION

SYSTEM

®

SMALL GREEN AND BLACK

WIRES – NOT USED

FIGURE 14

Step 3

Tachometer Operation:

If a tachometer is used, connect tachometer ignition sensing lead to the TACH terminal on the

HYFIRE®IV Electronic Ignition Control.

If the tachometer does not work after being connected to the TACH terminal, connect the

tachometer ignition sensing lead to the GREEN WIRE from the Ignition Control Harness.

Install the Mallory Fuel Injection and Tachometer Adapter Part No. 29074 to supply the

proper signal for the tachometer to operate.

Step 4

Secure all wires with cable ties to prevent contact extreme heat, sharp objects or moving

devices such as fans, belts and linkages.

Step 5

Recheck all wire and connections to ensure they are correct before applying power.

Step 6

Connect the battery () terminal cable. Start engine and check operation of the ignition system.

TACH/RPM OUTPUT

MAGNETIC

PICKUP

IGNITION CONTROL

FIGURE 15

10

OEM IGNITION AMPLIFIER

IGNITION COIL

GREEN

BLACK YELLOW

IGNITION CONTROL

HARNESS

OEM BALLAST OR

MALLORY BALLAST

RESISTOR (PN. 700)

+12VOLTS FROM IGNITION SWITCH

ALL OTHERWIRES ORIGINALLY

CONNECTEDTOTHE COIL (+)TERMINAL

IGNITION CONTROL

PLUG

RINGTERMINAL CONNECTOR

RINGTERMINAL

CONNECTOR

LONG BLACK

LONG RED

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

SMALL GREEN AND BLACK

WIRES – NOT USED

RED

+–

ALL OTHERWIRES

ORIGINALLY

CONNECTEDTOTHE

COIL (–)TERMINAL

(–) BATTERY (+)

HYFIRE

®

IGNITION

SYSTEM

®

FIGURE 17

GREEN

(NOT USED –TAPE LEAD)

BLACK

YELLOW

IGNITION CONTROL HARNESS

ALL OTHERWIRES ORIGINALLY CONNECTEDTOTHE COIL (+)TERMINAL

IGNITION CONTROL PLUG

RINGTERMINAL

CONNECTOR

LONG BLACK

(–) BATTERY (+)

LONG RED

SMALL RED

SMALL BLACK SMALL BLACK

SMALL GREEN

MAGNETIC PICK-UP DISTRIBUTOR

OR CRANKTRIGGER IGNITION

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

RED

IGNITION COIL

+

–

+12VOLTS FROM IGNITION SWITCH

HYFIRE

®

IGNITION

SYSTEM

®

SPADETERMINAL

CONNECTORS

FIGURE 18

IGNITION COIL

GREEN

GREEN

BROWN

BLACK YELLOW

IGNITION CONTROL HARNESS

OEM BALLAST OR

MALLORY BALLAST

RESISTOR (PN. 700)

NOTE:DO NOT

DISCONNECT

CONDENSOR

+12VOLTS FROM IGNITION SWITCH

ALL OTHERWIRES ORIGINALLY

CONNECTEDTOTHE COIL (+)TERMINAL

IGNITION CONTROL PLUG

RINGTERMINAL

CONNECTOR

GROUNDTO

ENGINE BLOCK

OR FRAME

RINGTERMINAL

CONNECTOR

LONG BLACK

LONG RED

MALLORY UNILITE DISTRIBUTORS,

MAGNETIC BREAKERLESS

DISTRIBUTORS, OR ELECTRONIC

ADVANCE DISTRIBUTORS (3-WIRE:

RED, BROWN, GREEN)

CHASSIS/FRAME GROUND

(DO NOT CONNECTTO

ENGINE BLOCK)

SMALL GREEN AND BLACK

WIRES – NOT USED

RED

RED

+–

(–) BATTERY (+)

HYFIRE

®

IGNITION

SYSTEM

®

FIGURE 16

11

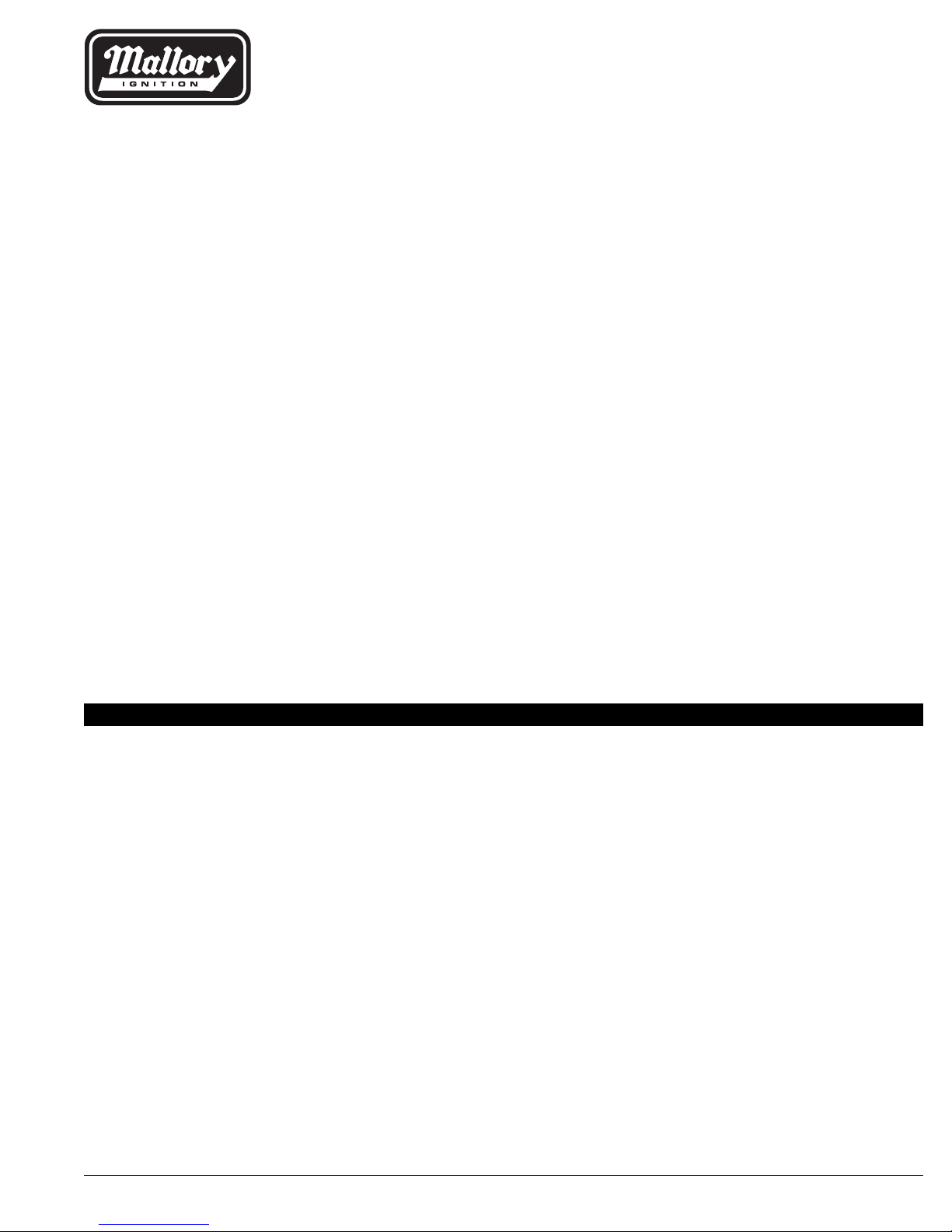

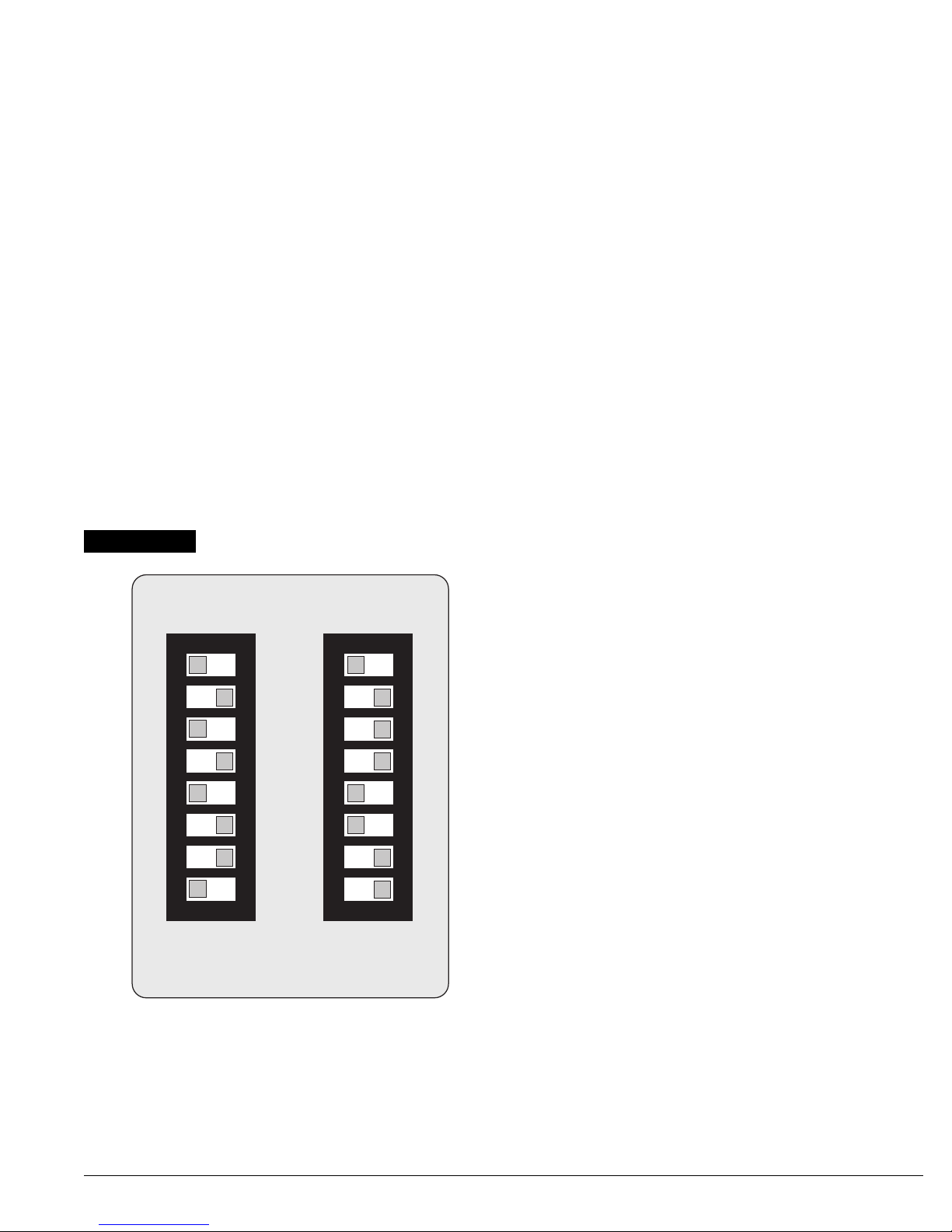

RPM LIMITER OPERATION

HYFIRE®IVC Ignition System Part No. 692 only

The HYFIRE

®

IVC Ignition System has a microcomputer controlled RPM limiting system. The RPM

limiting system has an engine protection RPM limiter and a staging control RPM limiter. The staging

control RPM limiter is triggered by applying 12 volts to the ORANGE WIRE. Connect the ORANGE

WIRE to 12-volt/line-lock, trans-brake or manual/toggle switches.

The RPM limiters are adjustable from 1,000 to 12,000 RPM in increments of 100 RPM. The

engine protection RPM limiter is factory set at 4,000 RPM.

NOTE:The engine protection RPM limiter must be set between 1,000 and 12,000 RPM. Any

other RPM setting outside the adjustment range stops the ignition system from operating.

The ignition system will resume operation once the engine protection RPM limiter is set

properly between 1,000 and 12,000 RPM.

If you are not going to use the engine protection RPM limiter, set the RPM value higher than

your engine will normally run (up to 12,000 RPM). Similarly, if you are not going to use the

staging control RPM limiter, avoid applying 12 volts to the ORANGE WIRE.

The RPM limiter switches for setting the RPM limiters are under the slide-back cover on top

of the housing. Loosen the four screws and slide the cover to see the RPM limiter switches.

You will see two sets of RPM limiter switches. One set of switches is marked HIGH SIDE.

These are the engine protection RPM limiter switches. One set of switches is marked

STAGE. These are the staging control set of RPM limiter switches. Between the two

switches is a number indicator. It has markings of 1000 and 100 along with markings of

8, 4, 2 and 1. Switches of each limiter are set ON to add combinations of 1, 2, 4 and 8 of

each switches hundred and thousand sections. Notice that the switches are marked ON in

their corner.

EXAMPLE: If you want to set the engine protection at 7,300 RPM, set the HIGH SIDE

switches thousand section to 8-off, 4-ON, 2-ON and 1-ON (4+2+1=7 thousand). Similarly,

set the HIGH SIDE switches hundred section to 8-off, 4-off, 2-ON and 1-ON (2+1=3

hundred). As stated earlier, if you are not going to use the engine protection RPM limiter, set

the RPM value higher than your engine will normally run (up to 12,000 RPM).

EXAMPLE: If you want to set the staging control at 5,600 RPM, set the STAGE switches

thousand section to 8-off, 4-ON, 2-off and 1-ON (4+1=5 thousand). Similarly, set the STAGE

switches hundred section to 8-off, 4-ON, 2-ON and 1-off (4+2=6 hundred). The staging

control RPM limiter is triggered by applying 12 volts to the ORANGE WIRE. Connect the

ORANGE WIRE to 12-volt/line-lock, trans-brake wire or manual/toggle switches.

NOTE: The RPM limiting systems will not work properly with odd-fire V6 applications. The

RPM limiting systems are not recommended as an engine speed governor. Similarly, forcing

engine RPM past the RPM limiter continuously for long intervals can cause problems

resulting from fuel build up in the exhaust system that may adversely affect exhaust oxygen

sensors (if used) and cause severe backfiring.

STAGE

ON

HIGH SIDE

ON

ADD FOR TOTAL RPM

ADD FOR TOTAL RPM

8000

4000

2000

1000

800

400

200

100

ON

ON

STAGING

RPM

EXAMPLE:

5,600 RPM

ENGINE

PROTECTION

RPM

EXAMPLE:

7,300 RPM

OPTIONAL IGNITION ACCESSORIES

Single Stage High Speed Retard Part No. 618-1

Mallorys Single Stage High Speed Retard is a finger tip adjustable ignition timing retard

control. The adjustment knob provides full adjustment range of 0°-15°. This retard is designed

with matching mating plugs so it can to be added between the HYFIRE®IV Electronic Ignition

Control and the Ignition Control Harness.

Multi Stage High Speed Retard Part No. 618-3

This is a finger tip adjustable 3-stage timing retard control with an adjustment range for the first

and second stage of 0°-15° and a range of 0°- 20° for the third stage. Each succeeding stage

overrides the previous stage to allow you to reduce (or add) ignition timing on a succeeding

stage. This retard is designed with matching mating plugs so it can to be added between the

HYFIRE®IV Electronic Ignition Control and the Ignition Control Harness.

Mallory Electronic Advance Computer Part Nos. 600-04, 600-06 and 600-08

This is a user programmable advance curve system using a CMOS microprocessor for

advance calculations. This allows you to select from 256 different advance curve combinations!

It is designed with matching mating plugs so it can to be added between the HYFIRE®IV

Electronic Ignition Control and the Ignition Control Harness.

Mallory Remote Timing Control Part No. 631

Mallorys Remote Timing Control allows you to change the ignition timing as you drive for

maximum performance, for better fuel economy or to avoid engine knock.

NOTE: The accessories listed above will not work properly with odd-fire V6

applications or point trigger distributors. They are not designed for marine use.

Mallory RPM Activated Switch Part No. 627A

This device is programmable from 3,000-10,800 RPM in increments of 100 RPM. It features

integral 5 amp relay contacts to operate 12-volt or ground circuits with connections for normally

open and normally closed operation. It works with any 8, 6 (includes odd-fire, semi-even fire,

and even-fire V6 engines), or 4 cylinder application and triggers from the tach output terminal

on the HYFIRE®IV Electronic Ignition Control.

Mallory Fuel Injection and Tachometer Adapter Part No. 29074 and 29078

Some applications with fuel injection or a tachometer need a voltage spike signal from the

negative side of the coil before they will operate properly. This signal changes once the

HYFIRE®IV Electronic Ignition Control is installed. Mallorys adapter provides the proper

signal to trigger most fuel injection systems and voltage/current triggered tachometers.

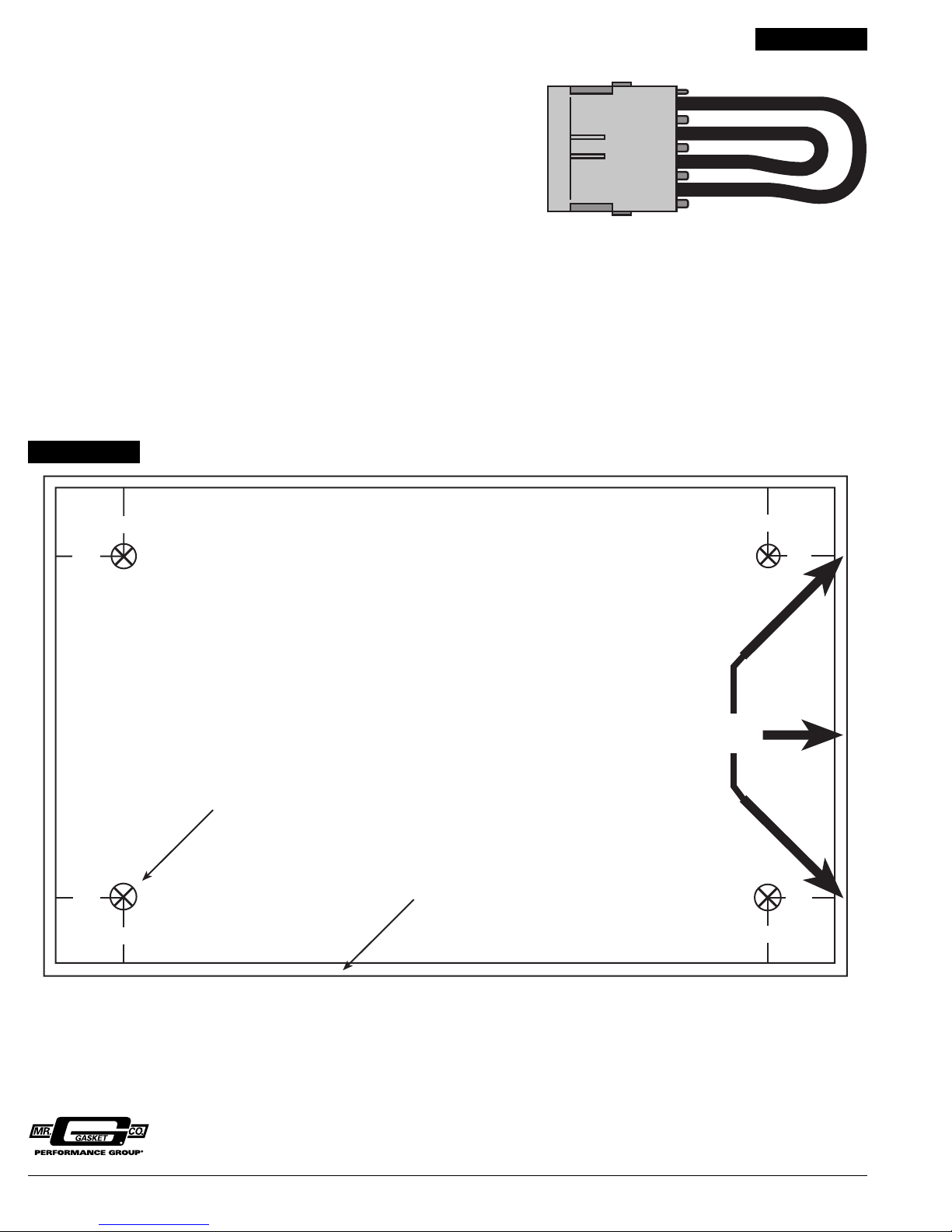

FIGURE 19

12

BYPASS CONNECTOR

The Bypass Connector (standard ignition bypass) fits into the mating plug of the Ignition

Control Harness to convert back to standard ignition. If you use the Bypass Connector, use

ignition ballast resistors designed for the particular distributor and coil in the wire from the

ignition switch. DO NOT put the Bypass Connector into the mating plug of a Mallory

HYFIRE®IV RPM Limiting Adapter, or Single or Multi Stage High Speed Retard. DO NOT

put the Bypass Connector into the mating plug of a Mallory Electronic Advance Computer or

Remote Timing Control. Use the Power Plug to convert back to standard ignition.Also, if you

are using a Mallory Fuel Injection/Tachometer Adapter (Part No. 29074), disconnect it (and

its diode if used) as part of converting back to standard ignition. The Bypass Connector

(standard ignition bypass method to convert back to standard ignition) does not work with

magnetic pickup distributors or crank trigger ignition.

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

FORM 1351

(REV. E) 10/99

Made in U.S.A.

Printed in U.S.A.

0.6"

0.6"

0.6"

0.6"

0.6"

0.6"

0.6"

0.6"

HYFIRE®IVA IGNITION SYSTEM

HYFIRE®IVC IGNITION SYSTEM

(BOTTOM PLATE)

MOUNTINGTEMPLATE

MAKE PROVISIONS 1" OUTSIDETHIS AREA

FORTHEWIRES COMING FROMTHIS ENDPLATE

HYFIRE

®

IGNITION

CONTROL OUTLINE

CENTER PUNCH

(4 LOCATIONS)

FIGURE 21

FIGURE 20

This manual suits for next models

2

Table of contents

Other Mallory Control Unit manuals