Malossi FORCE MASTER 2.1 User manual

5519529

20

ITALIANOENGLISH

20

ITALIANOENGLISH

FORCE MASTER 2.1

Assembly instructions

Control unit set-up

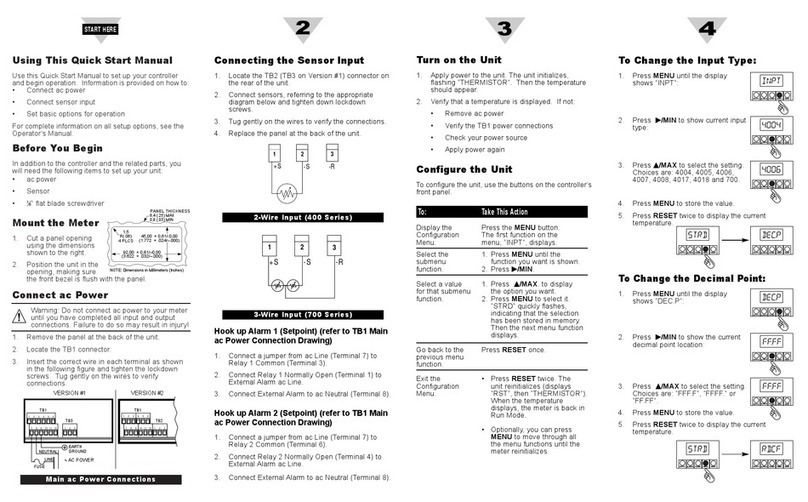

The control unit is equipped with 3

female connectors.

• Plug the cables into the relevant

connectors, which can be easily

identiied thanks to the colours.

CDI assembly

• Position the Force Master 2.1 CDI

under the seat (Fig. 1) and run the

wires to the engine, taking care that

they will not be damaged.

21

ITALIANOENGLISH

21

ITALIANOENGLISH

Injector

• Follow the wire coming out of the

injector and cut it at about 3 cm

from the connector, as shown in

Fig. 2.

• Connect the female faston 1

supplied into the kit to the original

connector 2by using the joint 3,

and carefully respecting the colours

of the wires (Fig. 3).

NB: pay attention to use the FEMALE

faston (1 - Fig. 3)!

• Close the joint using a pliers, such

as shown in Fig. 4.

• At this point connect the male

faston 4to the wiring of the vehicle,

using the joint as shown in Fig. 5.

Cables must be connected strictly

in accordance with the colours

shown in Fig. 3.

• Connect the control unit to the two

previously prepared connectors

(Fig. 6).

Ground

• Connect the black cable 5(negative

pole) coming out of the Malossi

control unit to the screw as shown

(Fig. 7).

22

ITALIANOENGLISH

22

ITALIANOENGLISH

TPS

• Identify the 5 cables TPS connector

located on the throttle body

(Fig. 8).

• On the yellow and black/grey

cables, apply the cable clamps

provided in the kit (Fig. 9).

• Make the following connections

using the cable clamp:

»Yellow Malossi control module

cable with yellow TPS cable

»Brown Malossi control module

cable with black/grey TPS cable

WARNING:

once the faston is connected to the

electrical tap connector we suggest

to tape the wire bunch, to avoid

electrical tap vibrations damaging

the wires.

Coil

• Locate the SMALL faston (orange

wire) connected to the original coil

and disconnect it.

• Insert the faston which comes from

the Malossi ECU (orange wire) to the

original coil.

• Connect the original wire to the

ECU’s bypass to complete the

23

ITALIANOENGLISH

23

ITALIANOENGLISH

circuit (Fig. 10).WARNING:

If you want to bring the vehicle

back to its original condition, you

must simply disconnect the cdi

connectors and reconnect the

Malossi connectors (Fig. 11).

Working

Control module status display

The control unit display shows the

status it is in, showing both the

functionality of the engine when

switched on and any possible errors

or supporting the user if the buttons

are pressed.

Buttons

The control unit is equipped with

3 buttons:

• “M” button: pallows to select the

dierent functions sequentially

• “-” e “+” buttons: only active in

certain operating modes, they allow

24

ITALIANOENGLISH

24

ITALIANOENGLISH

to increase or decrease the value

selected in the dierent functions

First power-up

Attention: when the key is turned

to start the vehicle, but the engine

is not started yet, the electronics

activates the power supply to all

actuators for a deined time of

approx. 3 seconds (“prime” phase).

The map and TPS calibration is

carried out starting with the vehicle

switched o.

TPS calibration

MIN adjustment

• Set the throttle knob to idle

• Press and hold the button (-) for the

entire calibration sequence

• Turn the key to ON

• The display shows lashing min

calibration logo

• If calibration successful, “OK”

appears

• If calibration was unsuccessful, the

message “OUT OF RANGE” appears

and it is necessary to repeat the

operation, checking that the

throttle is at idle

25

ITALIANOENGLISH

25

ITALIANOENGLISH

MAX adjustment

NB: You will need the help of a friend

to adjust the MAX.

• Set the gas knob to maximum

• Press and hold the button (+)

throughout the calibration

sequence

• Turn the key to ON

• The display shows the maximum

calibration logo lashing

• If calibration successful, “OK”

appears

• If calibration was unsuccessful, the

message “OUT OF RANGE” appears

and it is necessary to repeat the

operation, checking that the

throttle is at idle

MAP selection

• Press and hold button M throughout

the calibration sequence

• Turn the key ON : the display will

show the selected map

• To change the map, turn the key

OFF-ON (keeping the M button

pressed), until the desired map is

selected

NB: the control unit will only display

the pre-set maps

The vehicle can now be switched on

and used.

26

ITALIANOENGLISH

26

ITALIANOENGLISH

Working (Fig. 12)

These adjustments can be carried

out with the engine running, in

ventilated places.

Each time the ‘M’ button is pressed,

the display shows an indication

of the function being activated,

together with the switching on of a

dedicated LED on the edge of the

display.

In selection sequence, the

modes are:

1. “Low”: : shows the active

correction at low RPM (< 3000

RPM). If the engine is on, after

a few seconds of inactivity

it returns to the engine

screen display.

The “-” and “+” buttons reduce or

increase the injection correction

in 2% steps in the relevant RPM

ranges. When these buttons are

pressed, the selected correction

lashes. To conirm the selected

correction, it is necessary to wait

for the end of the lashing.

2. “Mid”: shows the active

correction at medium RPM

(between 3000 and 6000 RPM).

If the engine is on, after a few

seconds of inactivity it returns to

the engine screen display.

27

ITALIANOENGLISH

27

ITALIANOENGLISH

The “-” and “+” buttons reduce or

increase the injection correction

in 2% steps in the relevant RPM

ranges. When these buttons are

pressed, the selected correction

lashes. To conirm the selected

correction, it is necessary to wait

for the end of the lashing.

3. “High”: shows the active

correction at high RPM (> 6000

RPM). If the engine is switched

on, after a few seconds of

inactivity it returns to the engine

screen display.

The “-” and “+” buttons reduce or

increase the injection correction

in 2% steps in the relevant speed

range. When these buttons are

pressed, the selected correction

lashes. To conirm the selected

correction, it is necessary to wait

for the end of the lashing.

4. “Maps”: the active map is

displayed with the word “M”

followed by the map number and

a dierent map can be selected

using the “-” and “+” buttons. If

the engine is switched o, the

active map is always displayed. If

the engine is switched on, after

a few seconds of inactivity the

engine screen display returns.

Pressing the “-” and “+” buttons

shows the active map number on

28

ITALIANOENGLISH

28

ITALIANOENGLISH

the right-hand side of the display,

while showing the map about to

be activated in lashing mode on

the left. To activate the map, wait

for the end of the lashing and

the letter “M” on the left followed

by the map number that has

been activated on the right.

5. “Thr”: shows “T %” for a few

seconds, then the TPS opening

percentage is displayed. By

moving the throttle all the way,

the percentage displayed should

range from 0% to 100%. If the

stroke does not go from 0 to

100, TPS calibration must be

performed. The TPS value always

remains displayed regardless of

the engine state.

6. “Diag”: shows the letter “D” for

a few seconds, then the active

errors if present, otherwise it

shows “NO ERROR”. If the engine

is switched on, after displaying

the complete sequence of all

information, it returns the engine

screen display returns, otherwise

this information continues to run

on the display.

7. “Info”: displays the letter “I” for

a few seconds, then the ECU

mapping name and software

version are shown. If the engine

is running, after displaying both

29

ITALIANOENGLISH

29

ITALIANOENGLISH

information, the engine screen

display returns, otherwise this

information continues to scroll

across the display.

Diag

The Force Master 2.1 control unit is

equipped with a display that shows

possible diagnostic messages:

• “KO MAP” Calibration Error

There is an invalid calibration.

The control unit does not allow the

vehicle to start.

The calibration must be

reprogrammed, an operation only

possible at Malossi.

30

ITALIANOENGLISH

30

ITALIANOENGLISH

• “TUNING TPS” - TIncorrect

throttle calibration (for vehicles

where TPS calibration is required)

The throttle calibration procedure

was not carried out correctly by the

user and must be repeated.

The ECU may be behaving sub-

optimally, with the injection too

lean or too rich.

• “INJ1 S.C.” - Short-circuited

injector to battery positive

The connection to the wiring

harness has not been made

correctly and the injection output is

shorted to the battery.

The control unit goes into

protection mode and injection is

not implemented.

The control unit must be switched

o and on again to allow the vehicle

to start. If the error persists, it is

essential for the operator to check

the injection connections.

• “INJ1 O.C.” - Injector not

connected

MThe connection to the injector

is missing.

The engine cannot be started.

If the error persists, the

operator must check the

injection connections.

31

ITALIANOENGLISH

31

ITALIANOENGLISH

• “IGN LOST” - No coil connected

The connection to the coil

is missing.

The control unit may be restricted

in injection and is not injecting after

the original system’s limiter.

If the error persists, it is imperative

for the operator to check the

connection to the coil.

• “TPS N.C.” - Throttle connector

not connected (for vehicles where

TPS calibration is required)

The connection to the throttle cable

is missing.

The control unit may be behaving

sub-optimally, with the injection too

lean or too rich.

If the error persists, it is imperative

for the operator to check the

connection to the throttle cable.

• “TPS KWP2000” - OBD

connector for throttle check not

connected (for vehicles with

diagnostic connector)

The throttle reading via the OBD

connector is not correct.

The ECU may be behaving sub-

optimally, with the injection too

lean or too rich.

The operator must check the

connection to the OBD connector.

32

ITALIANOENGLISH

32

ITALIANOENGLISH

• “VBATT LOW” - Battery voltage

too low

The battery voltage has been below

11V for at least 10 seconds.

The control unit is behaving

normally but problems may arise in

the general operation.

The operator must make

appropriate checks on the system

because this problem cannot be

caused by the control unit.

• “VBATT HIGH” - Battery voltage

too high

The battery voltage has been above

15.5V for at least 5 seconds.

The control unit is behaving

normally but problems may arise in

the general operation.

The operator must make

appropriate checks on the system

because this problem cannot be

caused by the control unit.

Normal operation

When switched on, the control unit

display shows the status of

• Selected map

• Low/mid/high setting

After this, the RPM and THR status

bars remain active.

33

ITALIANOENGLISH

33

ITALIANOENGLISH

If errors are present, the Diag LED

will lash. It will then be necessary to

interrogate the control unit by going

to the speciic function to ind out

the error.

Technical details

• Carburation adjusting

• ± 14% al LOW / HIGH / MID

• RPM limiter : +1,800 RPM

• 4 dierent maps

• Temperature range = -30°C +80°C

• Minimum operating voltage = +7V

• Maximum operating voltage = +16V

• Average current consumption

<-200mA

• Environmental protection = IP65

Maps

The Force Master 2.1 CDI is

programmed with 4 base fuel curves:

• curve 0: original exhaust system,

Malossi cylinder kit, original

camshaft and original ilter;

• curve 1: Malossi with DB killer

exhaust system, Malossi cylinder kit,

original camshaft and Malossi ilter.

• curve 2: Malossi with DB killer

exhaust system, Malossi cylinder kit,

Malossi camshaft and original ilter.

• curve 3: Malossi with DB killer

exhaust system, Malossi cylinder kit,

34

ITALIANOENGLISH

34

ITALIANOENGLISH

Malossi camshaft and Malossi ilter.

35

ITALIANOENGLISH

35

ITALIANOENGLISH

We hope you found the above

instructions suiciently clear.

However, if any points are not

particularly clear, please contact

us completing the special form

inserted in the “contact” section on

our Internet site (malossistore.com).

We thank you in advance for any

comments and suggestions you may

wish to send us. So goodbye from us

all at Malossi, and please accept our

compliments. Have Fun. GOOD LUCK

and … see you next time.

The descriptions in this publication

are not binding. Malossi reserves

the right to make modiications, if

it considers them necessary, and

does not accept any responsibility

for any typographic or printing

errors. This publication replaces all

previous publications referring to the

updating matters contained therein.

WARRANTY

Look up warranty terms in our

website malossistore.com.

36

ITALIANOENGLISH

36

ITALIANOENGLISH

These products are reserved solely

for races in locations reserved for

those purposes and in accordance

with the regulations issued by the

competent authorities for sports

events. We decline any and all

responsibility for improper use.

37

Fig. 1

Other manuals for FORCE MASTER 2.1

3

This manual suits for next models

1

Table of contents

Other Malossi Controllers manuals