5

Beam Trolley Instruction Manual

MaltaDynamics.com | 800-494-1840

Visit www.MaltaDynamics.com for the latest user

instruction manual based upon date of manufacture.

INSTRUCTIONS FOR USE

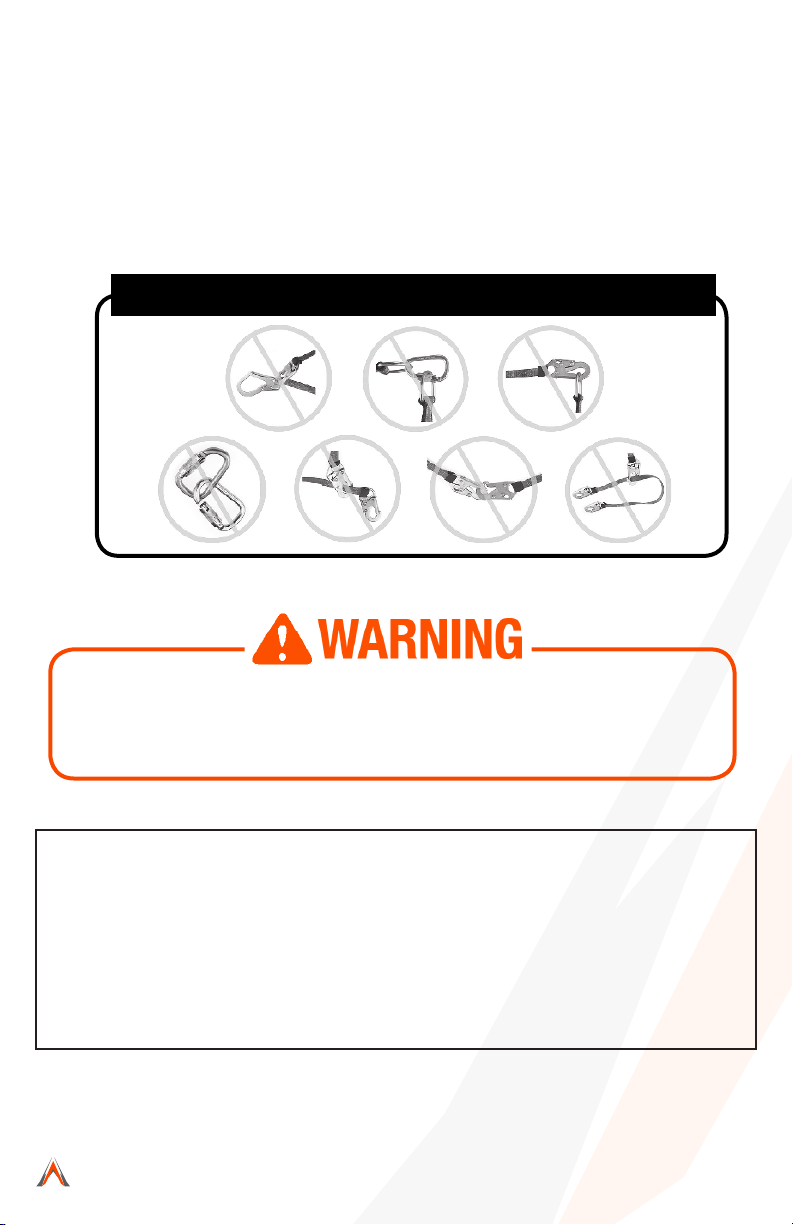

Do not alter or intentionally misuse this equipment.

Read This Instruction Manual Carefully Before Using

This Equipment.

1. A user must be of sound mind and body to properly and safely use this

equipment in normal and emergency situations. Users must have a

physician ensure they are clear of any medical conditions that may affect

the proper and safe use of this equipment in normal and emergency

situations.

2. Before using a personal fall arrest system, user must be trained in

accordance with the requirements of OSHA 29 CFR 1910.66 in the safe

use of the system and its components.

3. Use only with ANSI/OSHA compliant personal fall arrest or restraint

systems. The anchorage must have the strength capable of supporting a

static load, applied in the directions permitted by the system, of at least

5,000-lbf (22kN) in the absence of certification.

4. The user shall be equipped with a means of limiting the maximum

dynamic forces exerted on the user during the arrest of a fall to a

maximum of 8 kN (1800-lbf). In the EU these forces must be limited to 6

kN (1350-lbf).

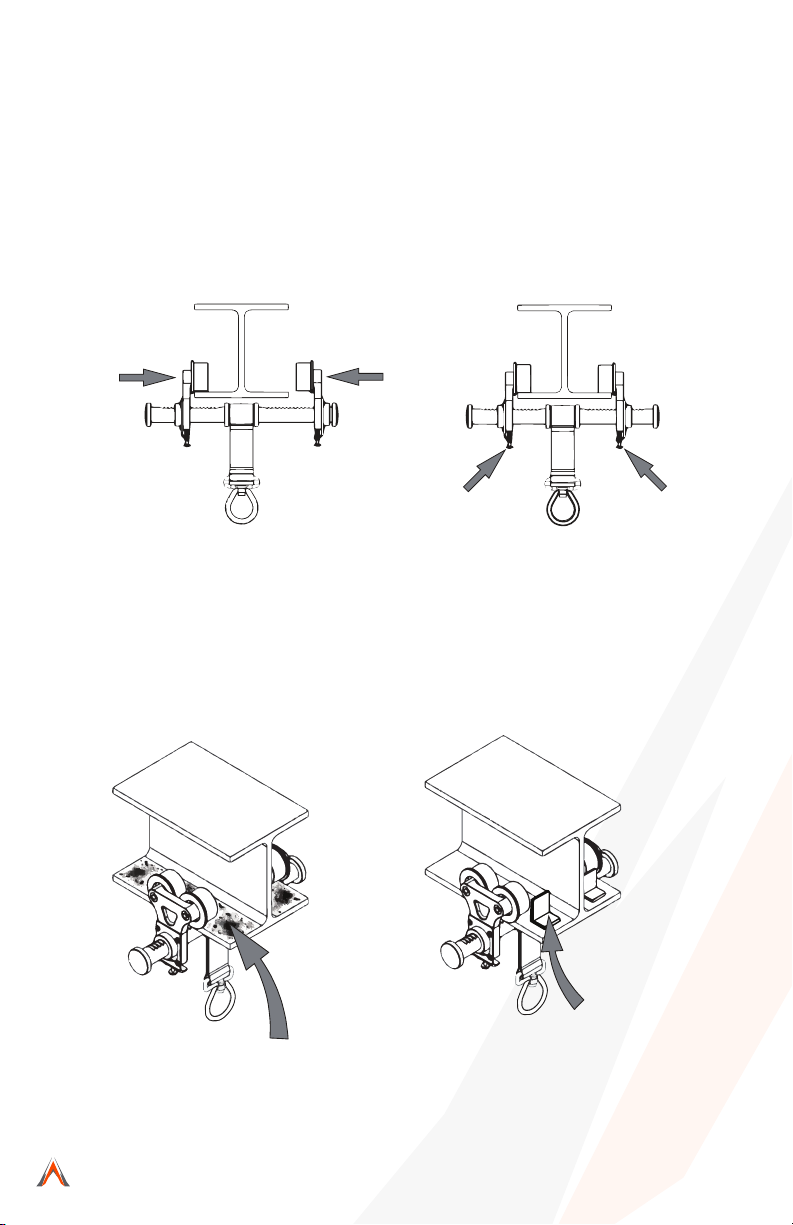

5. Use of this product must be approved by an engineer or other qualified

person to be compatible with any and all structural & operational

characteristics of the selected installation location and system to be

connected to this anchorage connector.

6. The anchorage connector must be inspected prior to each use for wear,

damage, and other deterioration. If defective components are found the

anchorage connector must be immediately removed from service in

accordance with the requirements of OSHA 29 CFR 1910.66 and

1926.502.

7. The anchorage connector should be positioned in such a way that

minimizes the potential for falls and the potential fall distance during use.

The complete fall protection system must be planned (including all

components, calculating fall clearance, and swing fall) before using.

8. A rescue plan, and the means at hand to implement it, must be in place

that provides the prompt rescue of users in the event of a fall, or assures

that users are able to rescue themselves.

9. After a fall occurs the anchorage connector must be removed from service

and destroyed immediately.