M&P HyperFlex 5 User manual

Our products are manufactured in compliance with: CEI 46-1 (construction parameters); EN 50117(screening efficiency); CEI EN 50289(SA test methods); IEC 60332-1-2(cables with LSZH jacket)

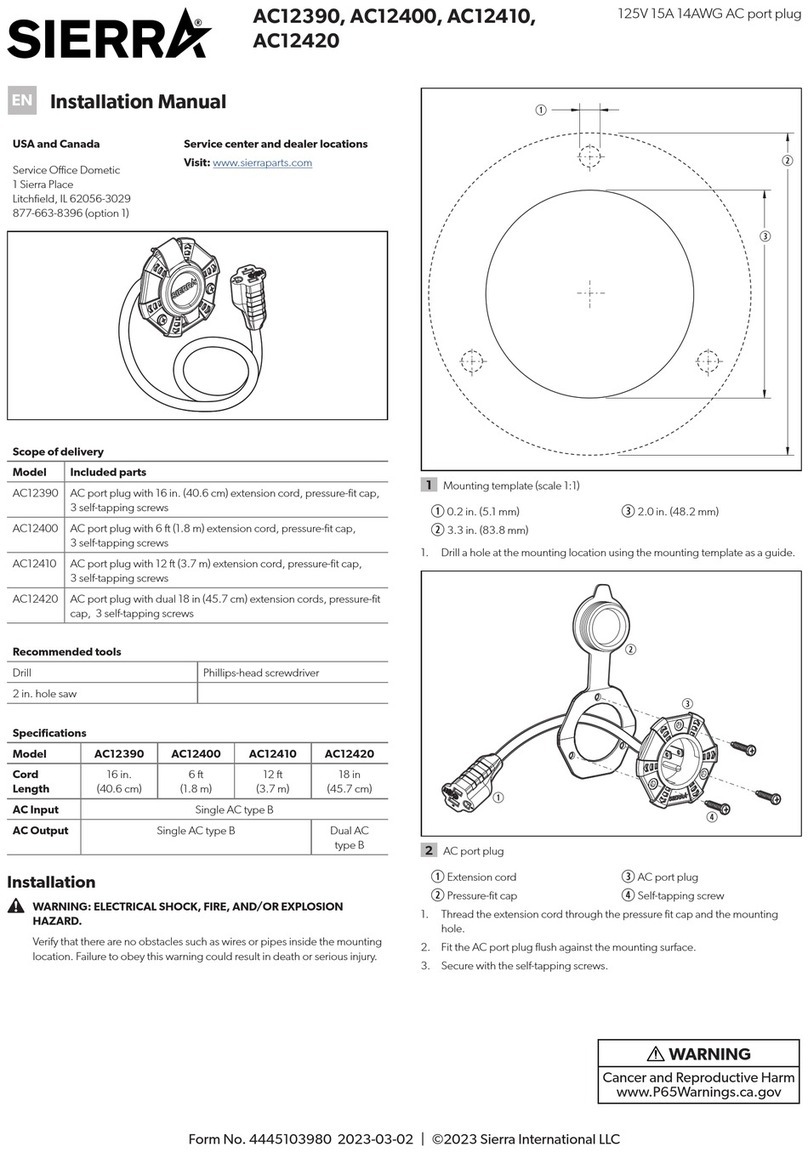

HyperFlex 5 /.212

/.212"

"

Crystal clear PVC jacket.

PVC Ø 5,4 mm ± 0,15

(0.212 inches ± 0.0059)

SRL

0,3-600 MHz >28 dB

600-1200 MHz >25 dB

1200-2000 MHz >22 dB

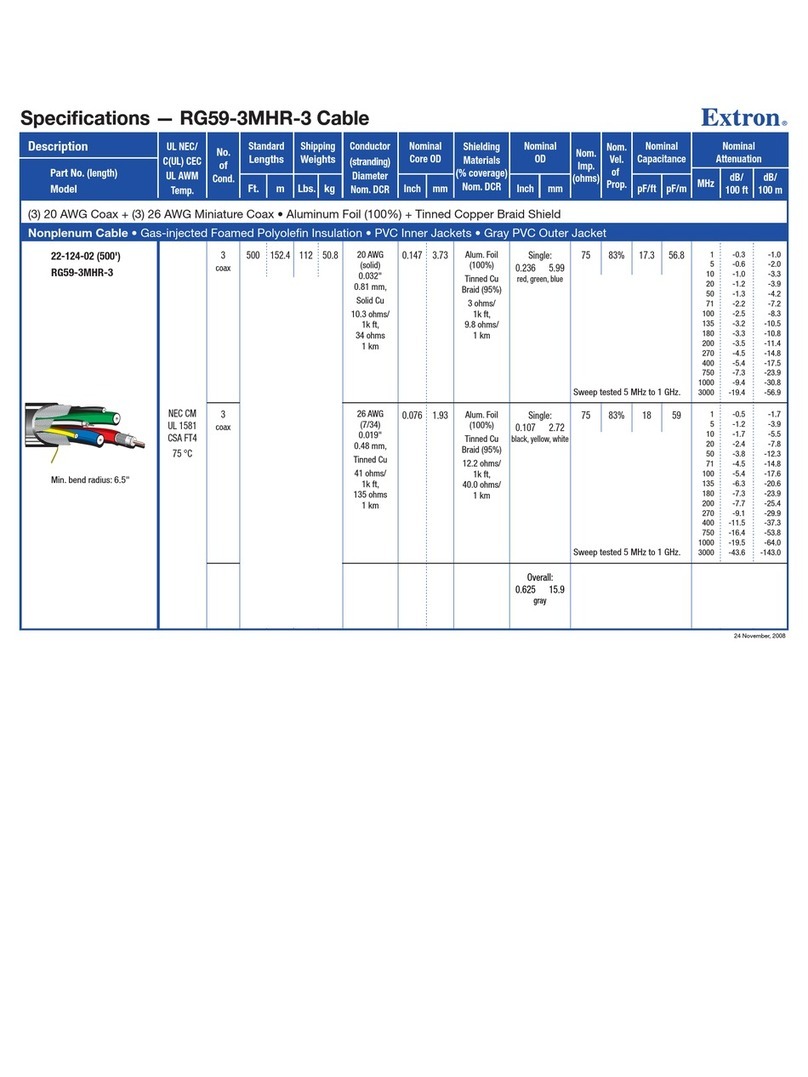

ATTENUATION at 20°C/68°F

FREQUENCY dB/100m dB/100ft

1,8 MHz 1,48 0,45

3,5 MHz 1,91 0,58

7,0 MHz 2,33 0,71

10 MHz 2,63 0,80

14 MHz 3,04 0,93

21 MHz 3,64 1,11

28 MHz 4,16 1,27

50 MHz 5,58 1,70

100 MHz 8,02 2,44

144 MHz 9,66 2,94

200 MHz 11,44 3,49

400 MHz 16,37 4,99

430 MHz 17,0 5,18

800 MHz 23,48 7,16

1000 MHz 26,46 8,07

1296 MHz 30,5 9,30

2400 MHz 42,58 12,98

3000 MHz 48,1 14,66

4000 MHz 56,95 17,36

5000 MHz 65,29 19,90

6000 MHz 72,92 22,23

POWER HANDLING (at 40°C/104°F)

FREQUENCY MAXP FREQUENCY MAXP

1,8 MHz 1274 W 400 MHz 115 W

3,5 MHz 987 W 430 MHz 111 W

7,0 MHz 809 W 800 MHz 80 W

10 MHz 717 W 1000 MHz 71 W

14 MHz 620 W 1296 MHz 62 W

21 MHz 518 W 2400 MHz 44 W

28 MHz 453 W 3000 MHz 39 W

50 MHz 338 W 4000 MHz 33 W

100 MHz 235 W 5000 MHz 29 W

144 MHz 195 W 6000 MHz 26 W

200 MHz 165 W

Inner conductor made of 19x0,29 stranded geometric

and concentric copper wires. Purity 99,99% annealed.

(annealed = thermal softening process)

Cu 19x0,29 mm - Ø 1,4 mm ± 0,15

(19x0.011 inches - 0.055 inches ± 0.0059)

ELECTRICAL DATA

Impedance @200MHz : 50 Ohm ± 3

Minimum bending radius:

Multiple bends/single bend 50/25 mm (1.97/0.98 in)

Temperature: -45°C to + 70°C (-49°F to +158°F)

Capacitance: 74 pF/m ± 2 (22.6 pF/ft ± 2)

Velocity ratio: 87 %

Screening efficiency:

100-2000 MHz >105 dB

Class A++

Inner conductor resistance: 14 Ohm/Km (4.3 Ohm/1000ft)

Outer conductor resistance: 11 Ohm/Km (3.4 Ohm/1000ft)

Tension test (spark test): 4 kV

Weight (100m/100ft): 4,2 Kg (9.25 lb)

Maximum peak power: 2900 WATT

Connectors: C.N.HF5M-S ; C.BNC.AC5M-S ; C.UHF.AC5M-S

High resistance copper screen (Cu) made by means

of 24 spools braiding machines. (50% more crosso-

vers if compared to traditional 16 spools machines.)

This braid is HIGHLY EFFECTIVE AGAINST

IMPULSIVE NOISES.

SCREENING PERCENTAGE: 88% 120 wires

High pressure physical injection

foamed polyethylene.

TRIPLE LAYER DIELECTRIC

FPE Ø 3,7 mm ± 0,05

(0.145 inches ± 0.05)

The copper foil has an applied PE-

coating, placed in order to prevent foil

cracking due to short radius bends.

SCREENING PERCENTAGE 100%

CU-POL

Pb

RoHS

COMPLIANT

2002/95/EG

UV resistant black PVC jacket.

PVC Ø 5,4 mm ± 0,15

(0.212 inches ± 0.0059)

HyperFlex 5

Crystal

/.212

/.212"

"

Datasheets_Layout 1 09/05/2017 10:17 Pagina 16

6

For step by step assembly instructions of connectors, please visit our website www.messi.it

Given a power fed to the X value (any value expressed in Watts), the actual power

output of the cable is shown in the table in the form of remaining percentage. (for ex-

ample, if we use a cable such as M&P-HYPERFLEX 5, entering 1000 Watts over a length

of 35m, at a frequency of 144 MHz, there remains 45,8 % of 1000). For maximum ap-

plicable power, see the Power Handling of the cable concerned. From these values,

have already been deducted the SRL values, typical of each one of our models, for the

respective frequencies.

REMEMBER: Make sure to match the line accurately!

M&P-HYPERFLEX 5 /.212"

length in meters

5 10 15 20 25 35 50 75 100 130 160 200 300

Frequencies (MHz)

3,5 97,7 95,6 93,5 91,5 89,5 85,6 80,2 71,8 64,3 56,4 49,4 41,4 26,6

Useful signal output (residual power %)

797,3 94,7 92,2 89,7 87,3 82,8 76,4 66,8 58,4 49,7 42,3 34,1 19,9

14 96,5 93,1 89,9 86,8 83,8 78,2 70,4 59,1 49,6 40,2 32,5 24,6 12,1

28 95,2 90,8 86,5 82,5 78,6 71,4 61,8 48,7 38,3 28,7 21,5 14,6 5,5

50 93,7 87,8 82,4 77,2 72,4 63,7 52,5 38,1 27,6 18,7 12,7 7,6

144 89,4 80,0 71,5 64,0 57,2 45,8 32,8 18,8 10,7 5,4

430 82,1 67,4 55,4 45,6 37,4 25,3 14,0 5,2

1200 69,8 48,9 34,2 23,9 16,6 7,9

2400 59,7 35,9 21,4 12,5 7,0

3000 55,9 31,5 17,4 9,3 4,7

4000 48,7 23,8 10,8 4,1

5000 40,8 15,9 4,2

6000 33,2 8,7

Temperature C° / F°

WATT

-10 / 14 -5 / 23 0 / 32 10 / 50 20 / 68 30 / 86 40 / 104 50 / 122 60 / 140 70 / 158

Frequencies / Frequenze (MHz)

1,8 1850 1850 1850 1732 1595 1432 1274 1086 899 713

3,5 1528 1476 1433 1342 1236 1109 987 842 697 553

71252 1210 1175 1100 1013 909 809 690 571 453

10 1109 1072 1041 975 897 806 717 611 506 401

14 960 928 900 843 776 697 620 529 438 347

21 802 775 752 704 648 582 518 442 366 290

28 701 678 658 616 567 509 453 387 320 254

50 523 505 491 459 423 380 338 288 238 189

100 364 352 341 320 294 264 235 200 166 132

144 302 292 283 265 244 219 195 166 138 109

200 255 247 239 224 206 185 165 141 116 92

400 178 172 167 157 144 129 115 98 81 64

430 172 166 161 151 139 125 111 95 78 62

800 124 120 117 109 101 90 80 68 57 45

1000 110 107 103 97 89 80 71 61 50 40

1296 96 92 90 84 77 69 62 53 44 35

2400 69 66 64 60 55 50 44 38 31 25

3000 61 59 57 53 49 44 39 33 28 22

4000 51 50 48 45 41 37 33 28 23 19

5000 45 43 42 39 36 32 29 25 20 16

6000 40 39 38 35 32 29 26 22 18 14

M&P-HYPERFLEX 5 /.212" (Power Handling/Temperature)

Connector assembly

Connector “N” type : C.N.HYF5M-S

Connector “UHF” type : C.UHF.AC5M-S

Make a circular cut on the black

PVC outer jacket at the indicated

length shown in the caliber (in mm).

Subsequently remove it.

After having made the rst cut,

as shown in picture 2, rotate the

cable 180 degrees and make a

second cut in the same way, in

order to facilitate the introduction

of component D (pic.4 and 5)

Insert component D after hav-

ing opened the braid as shown

in the picture. Push component

D between the foil and the braid

until it stops against the red PE

jacket.

Flatten the wires as shown in the

picture and cut the excess.

Cut and remove the tape and dielet-

ric for a lenght as shown in the pic-

ture (in mm).

Insert one of the two teon discs and

subsequently the central pin. Solder

the pin to the inner conductor, insert-

ing tin in the provided hole. Avoid

heating the pin for a too long time in

order not to damage with excessive

heat the cable dielectric.

(which is not made in teon!)

Insert the second teon disc as

shown in the picture. Insert the connector and fasten

accurately until the o-ring present

in component A, will be pressed

against the connector body. Inside,

the rubber component C (pic. 1)

will expand, granting optimal seal-

ing against moisture and a perfect

contact to ground.

Insert in the cable components A,

B, C and immediately after, make a

circular cut on the jacket at the in-

dicated length shown in the caliber.

(in mm). Subsequently remove it.

Insert component D after having

opened the braid as shown in

the picture.

Push component D between the

foil and the braid until it stops

against the jacket.

Flatten the wires as shown in the

picture and cut the excess.

Cut and remove the tape

and dieletric for a lenght as

shown in the picture.

Fasten together the connector and component A, until it will be pressed against

the connector body. Inside, the rubber component C (pic. 1) will expand, granting

optimal sealing against moisture and a perfect contact to ground.

Insert the connector and solder it with

tin to the inner conductor (see picture

above). Avoid heating for a too long

time in order not to damage with

excessive heat the cable dielectric

(which is not made in teon!)

1 2 3 4

A

B

CDD

5 6 7 8

1A

B

C

18 mm

2 3

D

4

7

56

D

Messi & Paoloni srl

Via G. Conti 1 - 60131 - Ancona

Tel. +39.0712861527

Fax. +39.0712861736

C.N.HYF5M-S C.UHF.AC5M-S

CONNECTORS AVAILABLE FOR

M&P-HYPERFLEX 5 /.212"

Messi & Paoloni srl

Via G. Conti 1 - 60131 - Ancona

Tel. +39.0712861527

Fax. +39.0712861736

C.BNC.AC5M-S

This manual suits for next models

1

Popular Cables And Connectors manuals by other brands

Extron electronics

Extron electronics Skew-Free UTP23SF-4/100 Brochure & specs

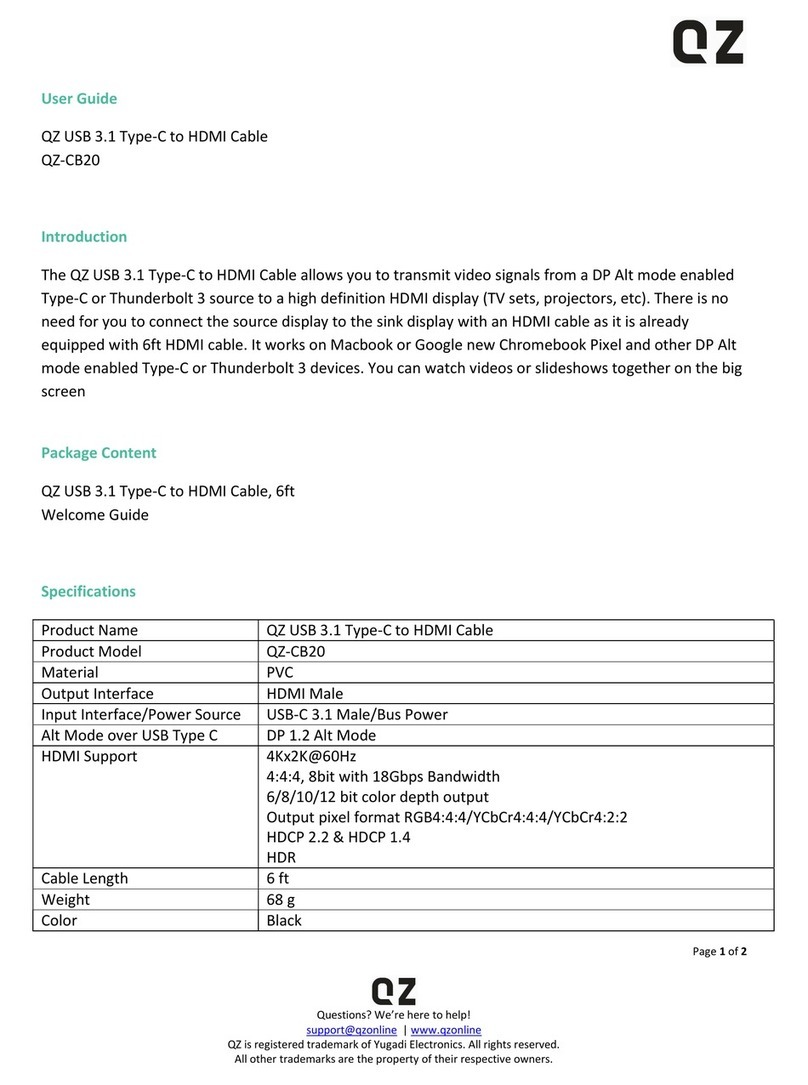

QZ

QZ QZ-CB20 user guide

DVIGear

DVIGear DVI-5312b user guide

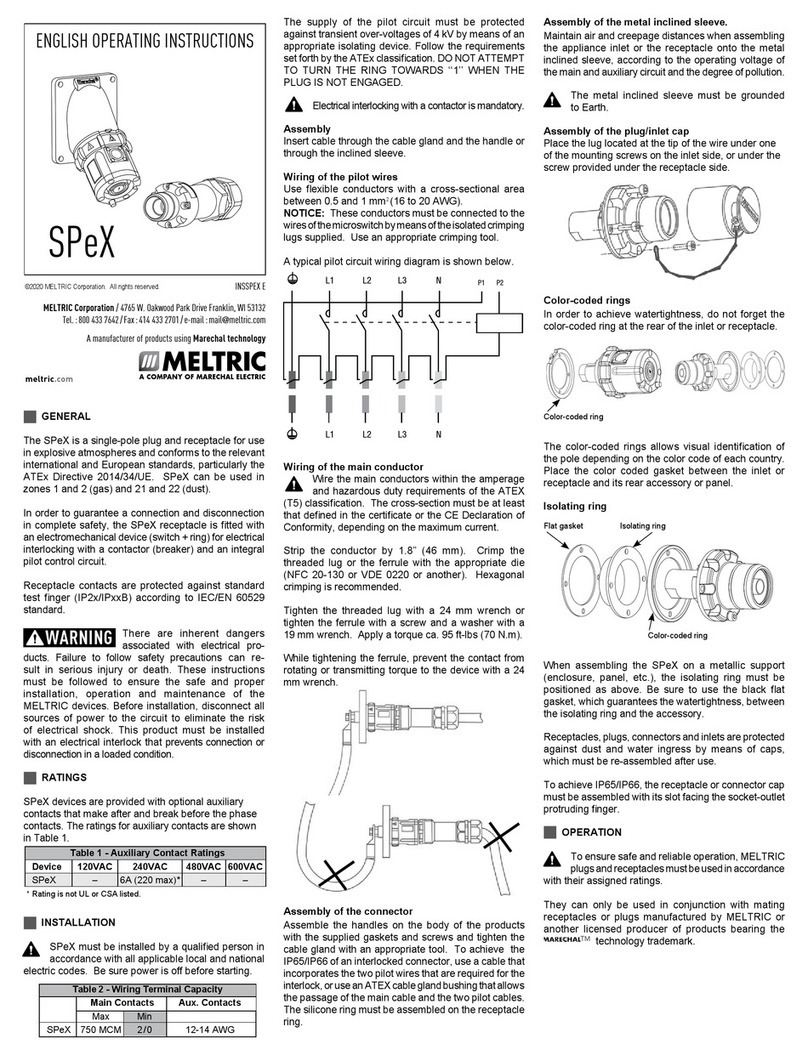

Meltric

Meltric SPeX operating instructions

NORAUTO

NORAUTO NO3196 Installation Manual and Security Information

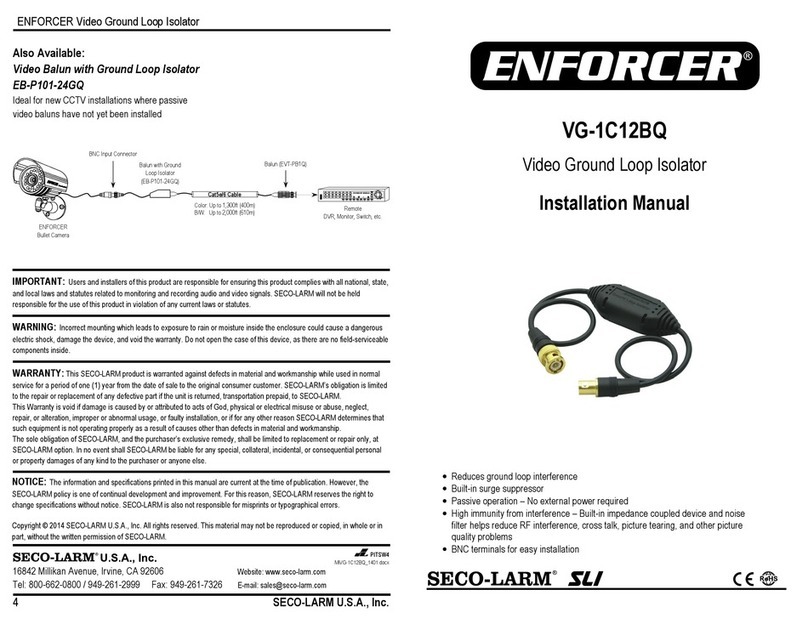

SECO-LARM

SECO-LARM ENFORCER VG-1C12BQ installation manual