Manning MSP250 User manual

MSP250

Manual

Sampling Pump

Operation Manual

17 April 2014

© 2014 Manning Environmental Inc. All rights reserved.

1

MSP250 Manual Sampling Pump Operation:

1. Connect battery by sliding connector on red wire onto positive (red) battery post. Slide connector on

black wire onto negative (black) battery post.

2. Close case and latches.

3. Place intake hose in source fluid.

4. Place discharge hose in sample container.

5. To take a sample, push switch upward (toward “draw”). To purge (reverse the pump), push switch

downward (toward “purge”).

6. Return switch to the center “off” position to stop pump.

Warnings:

1. DISCONNECT BATTERY BEFORE REMOVING CLEAR PUMP COVER OR INJURY

MAY OCCUR.

2. If MSP250 Manual Pump is used with the handle pointing upward, lay case flat and run pump to

completely clear fluid from lines or spatter may occur.

3. Keep inside of electronics enclosure and battery dry at all times.

Replacing Pump Tubing

The pump tubing on the MSP250 Manual Sampling Pump does not need to be replaced frequently;

however, it should be inspected periodically for wear or damage. Watch for cracking or creasing, which

can indicate it is time to change the tubing. Manning recommends using PharMed® tubing for the best

performance.

To replace the pump tubing:

1. Loosen the four thumbscrews that hold the pump in place. There are four sealing washers attached

to the pump body with adhesive. Make sure these stay in place.

2. Remove the four long screws.

3. Separate the two halves of the clamshell pump and remove the old tubing.

2

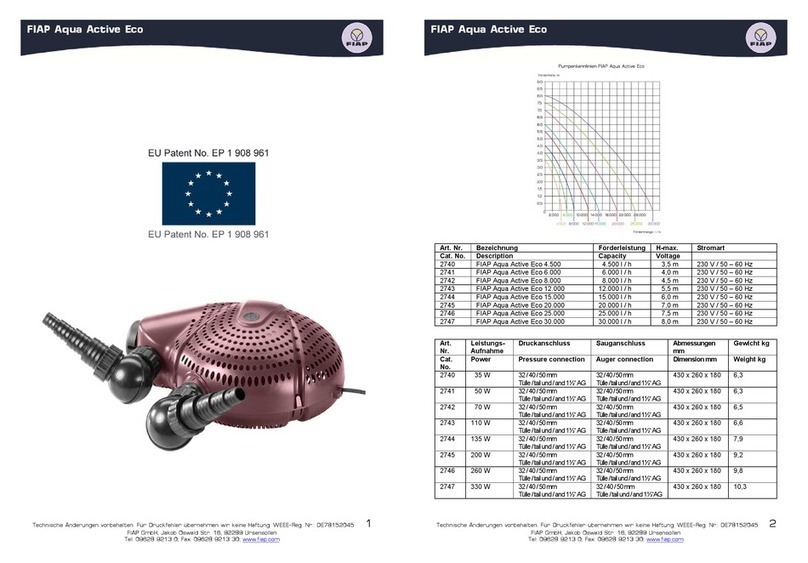

4. Orient the pump housing as shown below. (Note: The “bottom,” or the side that fits against the

case, is pointing upward.)

5.

Orient rollers in ½ of pump housing as in

picture.

Note roller position.

6.

Fold pump hose in half, aligning ends and

forming loop at other end.

7.

Place hose around pump rollers, making sure to

place hose into grooves.

3

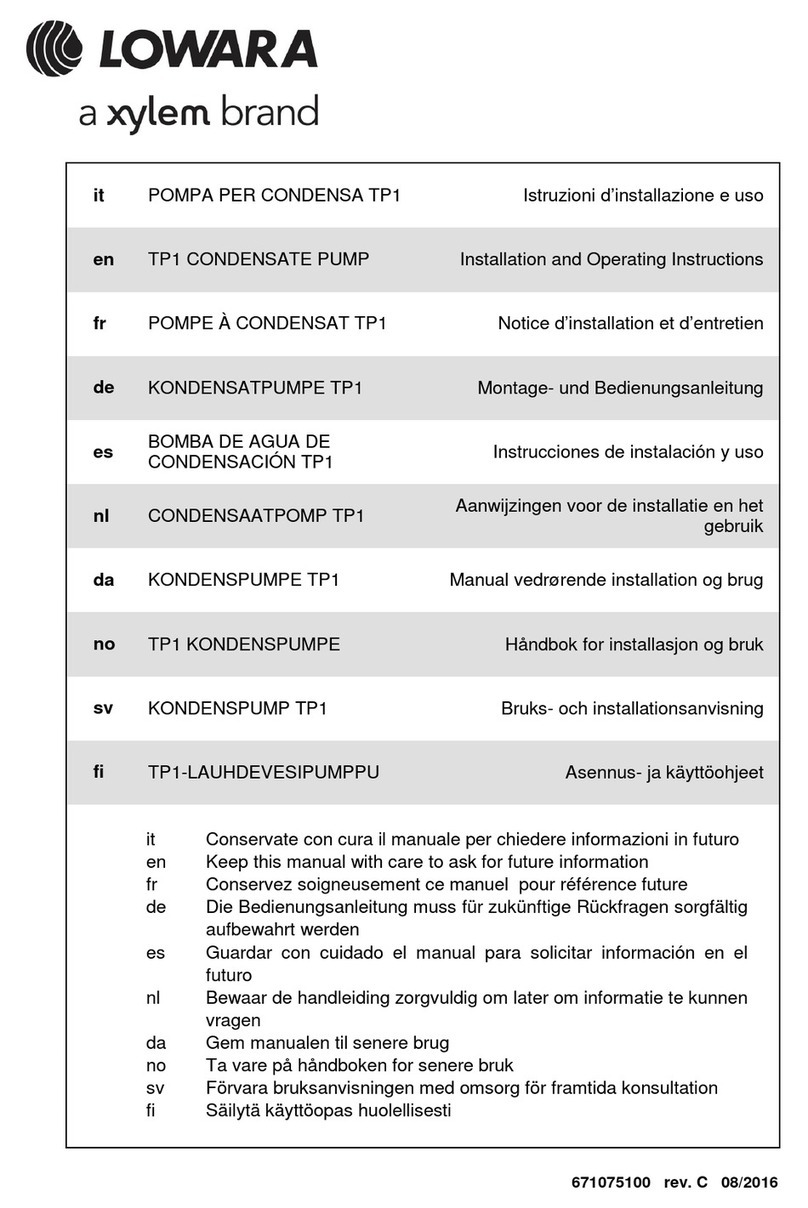

8.

Using the pump tool* included in the pump kit,

rotate rollers clockwise while pressing hose in

gap between rollers.

*Note: Pump tool is stored in a slot at the

top left of the foam insert in case.

9.

Continue until hose is in place.

10.

Once hose is in place, put on other half of pump

housing.

4

11.

Hold two halves together and rotate rollers

clockwise using the pump tool.

Set aside.

12. To re-attach pump housing, line up the arbor shaft with the pump motor shaft, and place clamshell

onto motor.

13. Rotate the clamshell to align the four screw holes.

14. Replace the long thumbscrews and finger tighten.

Installing and Removing Hose Fittings- ¼” Hose

This procedure is for installing and removing the quick-disconnect fittings used on units

manufactured before May 2012 from the ¼” ID PVC intake hose. It is also applicable for the

installation and removal of strainers from the hose.

Installation of Fitting

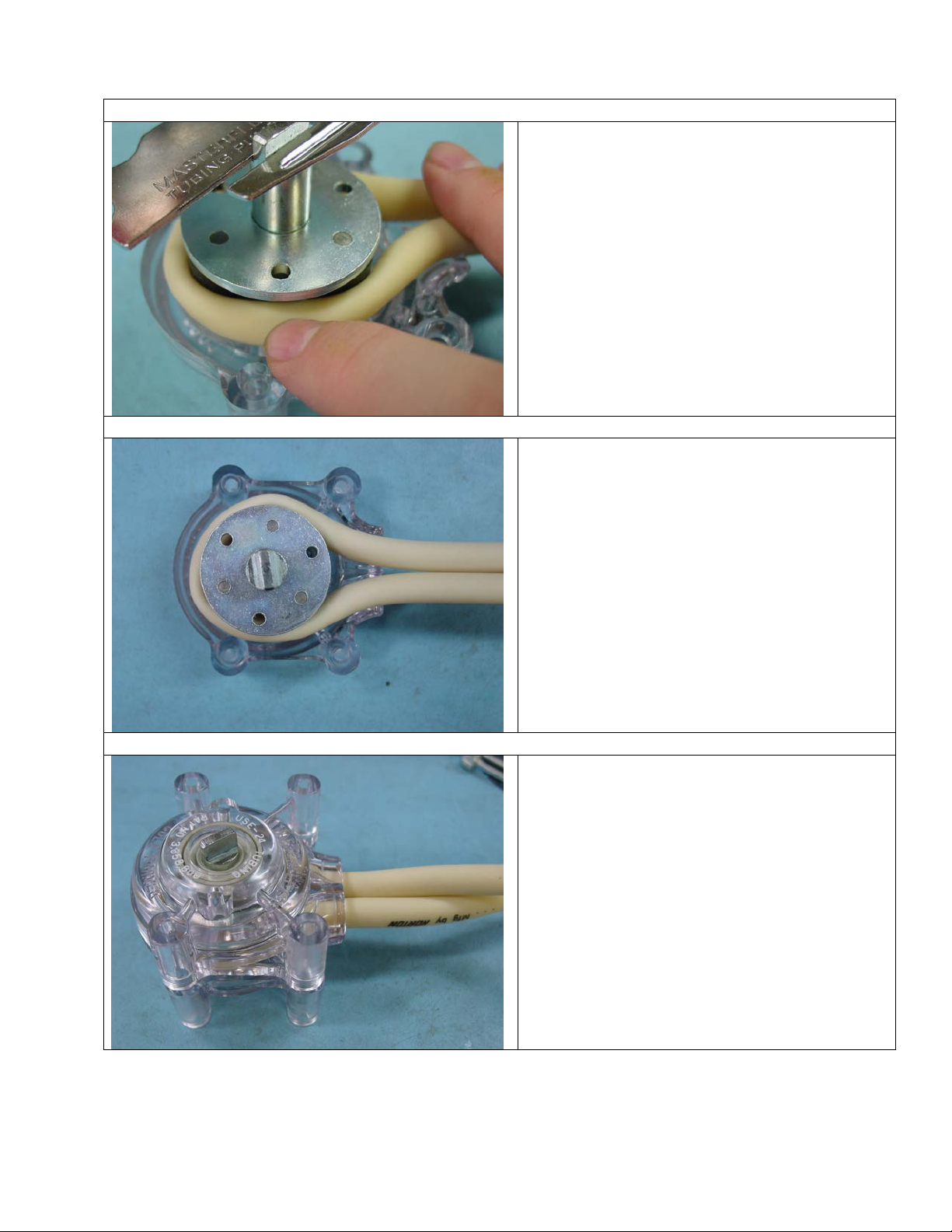

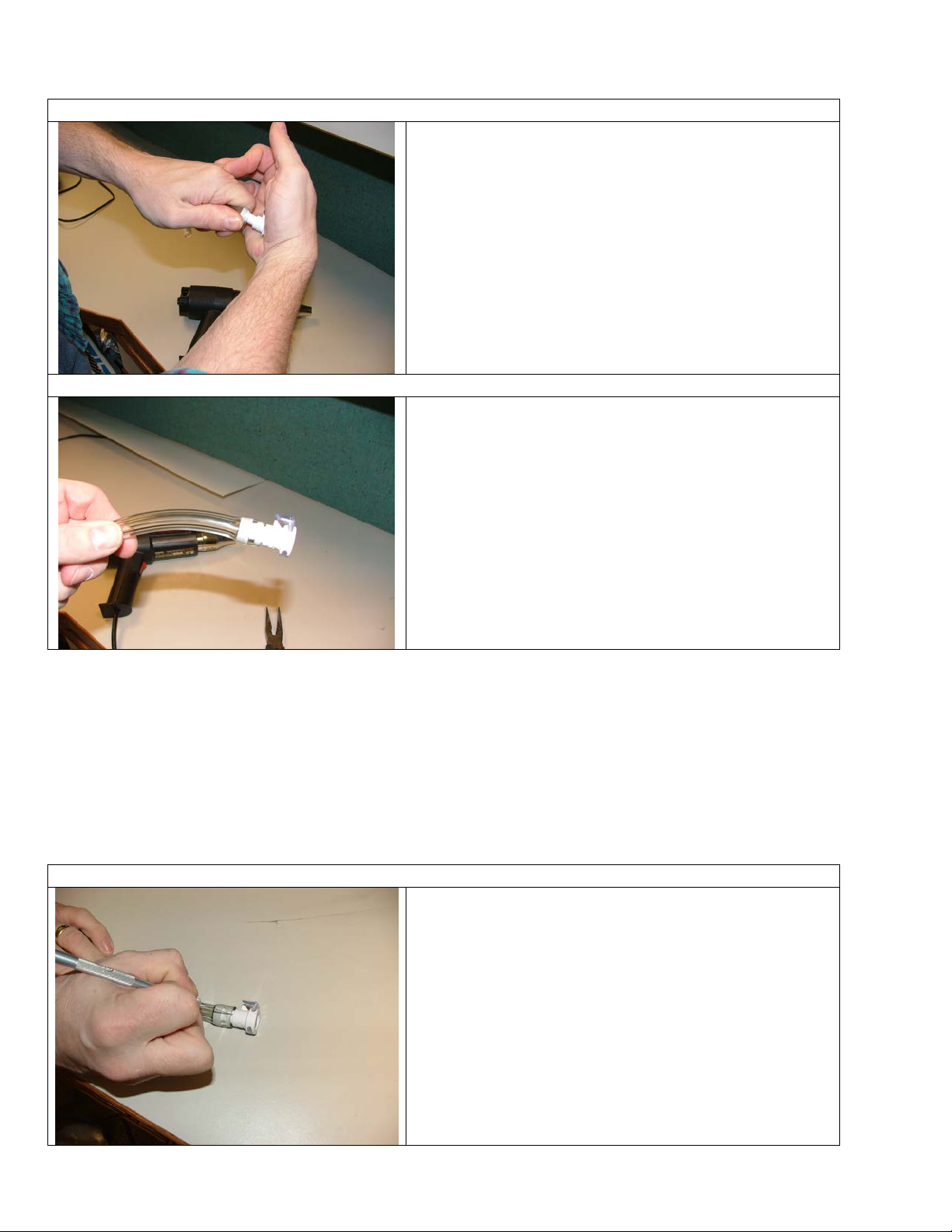

1.

End of intake hose should be cut clean and straight.

Using a heat gun (a hair dryer set on high with a

concentrator can be used if a heat gun is not available),

heat the end of the hose until it is very warm to the

touch. Do not melt the hose.

5

2.

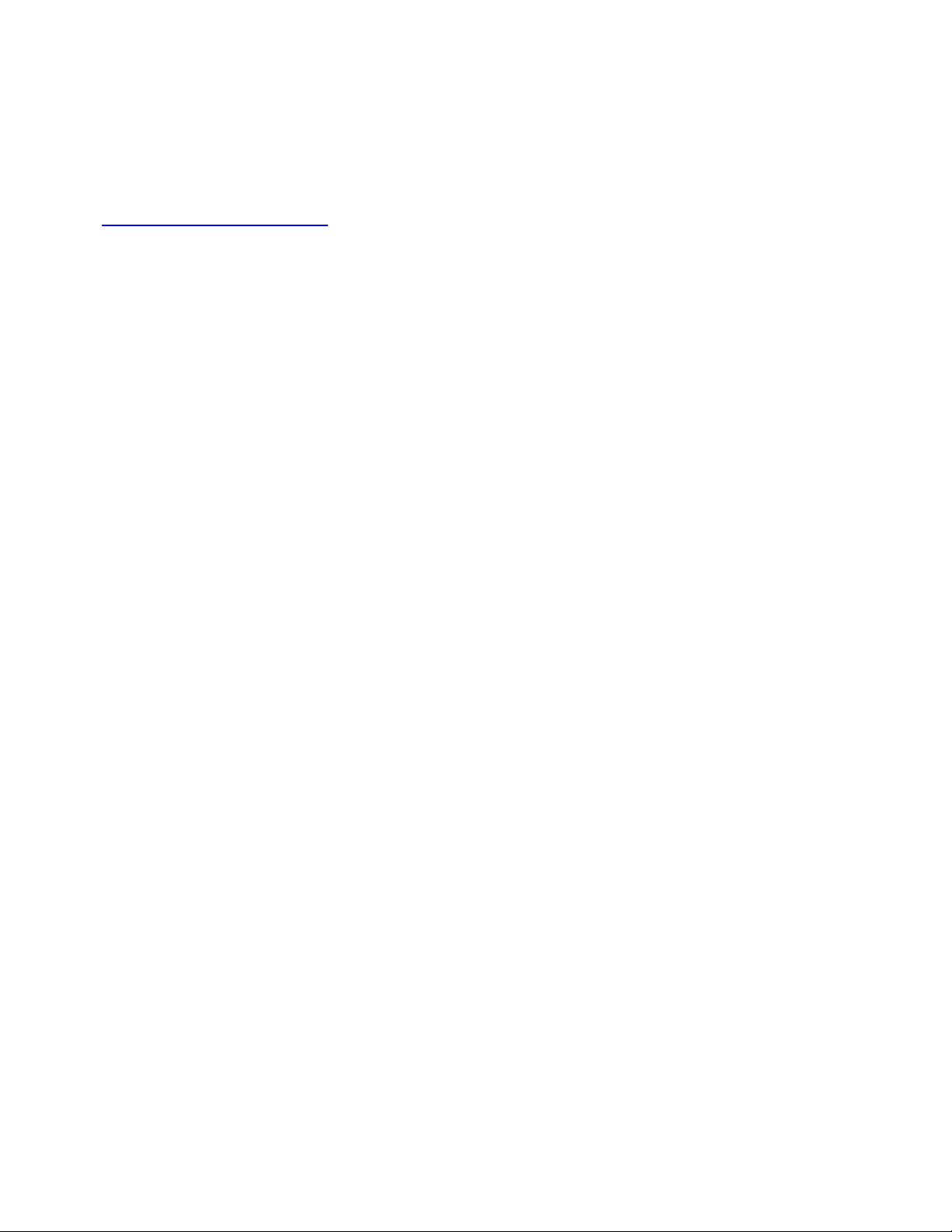

Insert a pair of round-nose pliers into the end of the

hose.

3.

Stretch out the hose with the pliers. Rotate the pliers 90

degrees in the hose and stretch again.

4.

Quickly remove the pliers and insert the fitting into the

end of the hose.

6

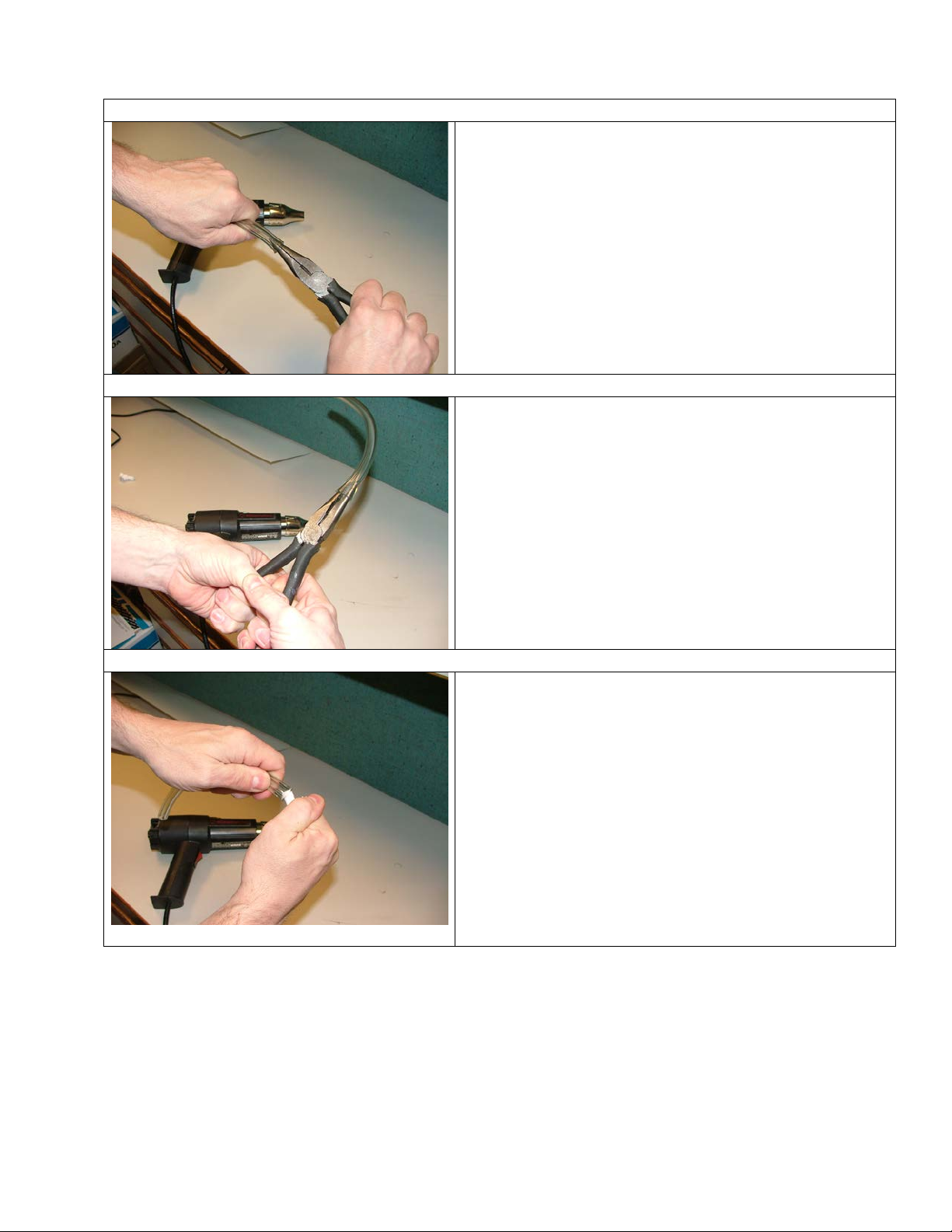

5.

Press the fitting into the hose using a wiggling motion.

6.

Make sure that barbed end of fitting is fully inserted

into hose

Removal of fitting

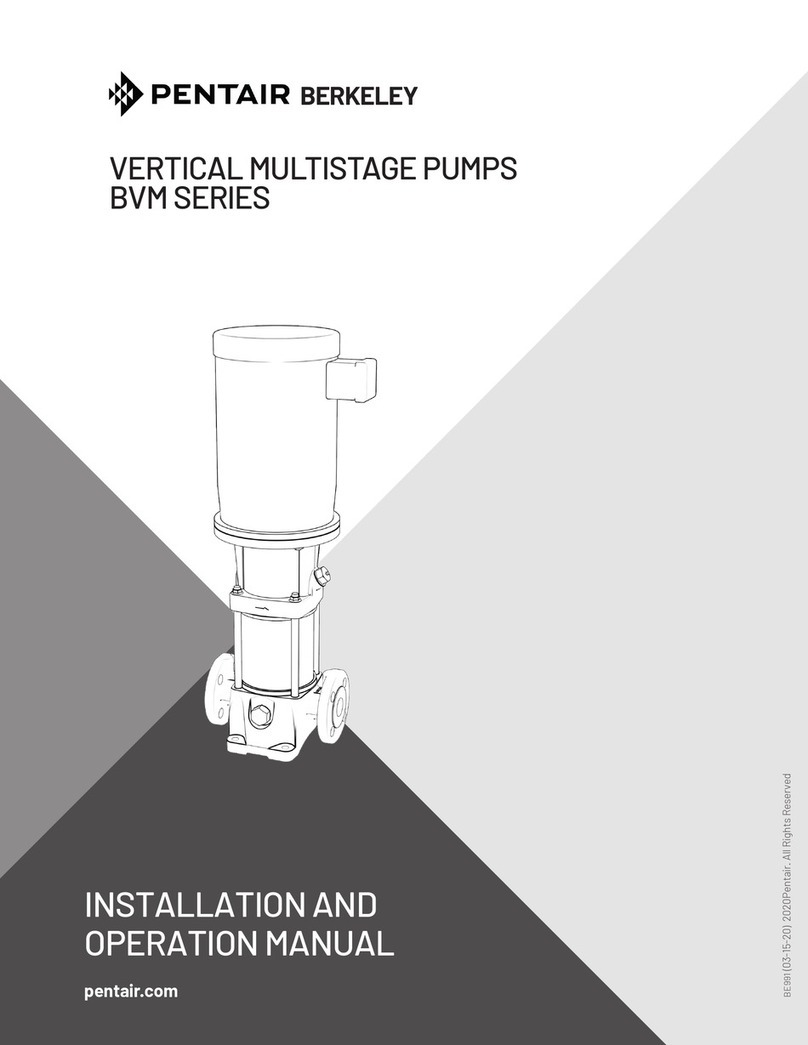

1.

Using a knife, cut a slit in the hose along the side of the

connector.

7

2.

Remove fitting using a wiggling motion.

Intake Hose

The sampler is supplied with an extra male and female hose couplings to attach intake hose to the pump

tubing. The MSP250 uses ¼” internal diameter intake hose, which is available from Manning as an

accessory. Intake hose should always be ¼” internal diameter. If a larger internal diameter hose is used,

the coupling may not fit and there will be a loss of performance.

In May of 2012, Manning changed hose couplings. The current couplings are white in color, with a

quarter-turn locking design. The female couplings rotate to help prevent hose kinking. Operation of the

hose couplings is detailed below.

8

If there are solids or debris in the water being sampled, Manning recommends using a strainer on the

intake hose to prevent clogging. Strainers are available from Manning in PVC or stainless steel.

If you have any questions, please call Manning Technical Support at (800) 863-9337 extension 205 or

email service@manning-enviro.com.

9

Specifications

Size....................................... Controller, including Pump Housing: W 12.5 in. (31.75 cm) ×H 7.00 in. (17.78 cm) ×D 10 in. (25.4 cm)

Weight (dry)........................... 10 lbs (4.54 kg). Weight includes battery.

Environmental Protection....... NEMA 4X/NEMA 6 structural resin housing around electromechanical components

Sampler Pump....................... ¼-inch peristaltic 12 VDC pump with impact and corrosion-resistant plastic pump body, and dual-roller

mechanism

Maximum Lift......................... 28 ft (8.5 m)

Transport Velocity.................. 927 ml per minute @ 10 ft. head height

Power Requirement............... 12VDC 8-Amp hour battery

Warranty:............................... One year from date of shipment.

Accessories

MSP250 Manual Sampling Pump* Spare Parts/Accessories

• Replacement Pump Tubing

¼-inch Pharmed (pre-cut 18-inch length) P/N 889924

¼-inch Pharmed (bulk by the foot) P/N 566927

• Replacement Battery

Standard 8-Amp hour battery P/N 690539

• Battery Charger

Standard-output 3-stage Charger (12 VDC @ 750 mA; for 110/220

VAC operation) P/N 885400*

• Hose Couplings

Female P/N 552113

Male P/N 5521112

• Intake Hose

¼-inch bulk clear intake hose P/N 566926

Please specify required length in feet.

• Sample Containers

One 2.5-gallon polyethylene bottle w/cap P/N 687547

One 4-gallon polyethylene bottle w/cap P/N 687551

One 5-gallon polyethylene bottle w/cap P/N 687535

One 2.5-gallon glass bottle w/Teflon lid liner P/N 889715

5-gallon polyethylene pail with splashguard & transport lid

P/N 889721

• Strainers

¼-inch PVC P/N 889146

¼-inch stainless steel P/N 579595

* Basic sampler includes one (1) 8-amp hour battery, one (1) standard-output battery charger, one (1) 18” pre-cut length of pump tubing with

a set of male and female hose couplings attached, and one (1) additional set of hose couplings (male & female). Bottle, intake hose, and

strainer are additional.

Engineering Specification

1.

The controller enclosure is made of

structural resin with NEMA 4X/NEMA 6

ratings.

2.

All wetted parts have a minimum internal

diameter of ¼-inch, and are stainless steel

or PVC (optional strainer), PVC (sampling

hose), and Pharmed (pump tubing).

3. The sampler incorporates a 3-roller ¼-inch ID

peristaltic pump

4. The sample liquid must be under forced flow at

all times and shall not pass through a metering

chamber, distribution plate, or valves. .

5. The sampler is capable of a transport velocity

of 927 ml per minute @ 10 ft. head height.

6. The sampler has an optional weighted

strainer of PVC or stainless steel.

7.

Sampler is suitable for 110 or 220V

oper

ation with standard battery

charger.

8. This sampler is a Manning ¼-inch

MSP250 Manual Sampling Pump.

MSP250 Manual Sampler 04/24/2012

For parts and service, please contact: Manning Environmental Tech Support (800) 863-9337 x 205

or email service@manning-enviro.com

Headquarters and Sales:

Manning Environmental, Inc.

101 Bar T Drive

Florence, Texas 76527-4445

Phone:(800) 863-9337

Fax: (254) 793-9965

Email: sales@manning-enviro.com

Web: http://www.manningenvironmental.com

In the interest of improving and updating its equipment, Manning reserves the right to alter specifications for equipment at any time.

10

Manning Environmental Limited Factory Warranty

Manning Environmental, Inc., warrants this product to the original purchaser against any defects that are due to

faulty workmanship or material for a period of one year (365 days) from the date of shipment.

During the warranty period Manning Environmental, Inc. will repair or replace, at its sole discretion, any defective

equipment or parts. Manning’s liability is strictly limited to repair and/or replacement. Any product repaired or

replaced under this warranty will be warranted only for the remainder of the original product warranty period.

This warranty does not apply to consumable products or consumable components of products such as, but not

limited to tubing, intake hose, differential pressure switches and bottles.

Items may not be returned without authorization from Manning Environmental, Inc.

This warranty applies only to products sold under the Manning trademark and is the sole express warranty made

by Manning Environmental, Inc. All implied warranties, including without limitation, the warranties of

merchantability or fitness for a particular purpose, are disclaimed.∗

Limitations:

This warranty does not cover the following:

1. Damage caused by acts of God, natural disaster, labor unrest, acts of war (declared or undeclared),

terrorism, civil strife or acts of any governmental jurisdiction

2. Damage caused by normal wear, neglect, misuse, accident, corrosion or improper application or

installation

3. Damage caused by any repair, attempted repair or modifications not authorized by Manning

Environmental, Inc.

4. Any product not used in accordance with the instructions furnished by Manning Environmental, Inc.

5. Freight charges to return merchandise to Manning Environmental, Inc.

6. Freight charges on expedited or express shipment of warranted parts or products.

7. Travel and lodging fees associated with on-site warranty repair

8. Manning 6.1 cubic foot refrigerators, which are covered under the refrigerator manufacturer’s warranty

9. Labor performed at the factory to clean the equipment so that it can be safely and properly repaired

This warranty constitutes the final, complete, and exclusive statement of warranty terms. Manning Environmental,

Inc. does not authorize any other person to make any other warranties or representations on its behalf.

In no event shall Manning Environmental, Inc. be liable for any incidental or consequential damages of any kind

for breach of warranty or negligence. The remedies of repair or replacement as stated above are the exclusive

remedies for the breach of this warranty.

A Return Material Authorization (RMA) must be obtained prior to sending any equipment to Manning for warranty

service. Contact the Manning Service Department at:

Manning Environmental, Inc.

101 Bar T Drive

Florence, Texas 76527-4445

Phone: 254-793-9955, Fax: 254-739-9965

∗Some states within the United States do not allow the disclaimer of implied warranties and if this is true in your state the above limitation

may not apply to you. This warranty gives you specific rights- you may also have other rights that vary from state to state.

Table of contents

Popular Water Pump manuals by other brands

Stryker

Stryker EOLE Service manual

General Pump

General Pump EP1506G8 Instructions for the installation and use

Kessel

Kessel SECOH SLL Series instruction manual

Pentair

Pentair Berkeley BVM Series Installation and operation manual

Agilent Technologies

Agilent Technologies Turbo-V 903 user manual

Pentair Jung Pumpen

Pentair Jung Pumpen MULTIDRAIN Series instruction manual

vacuubrand

vacuubrand MZ 2 VARIO-SP Instructions for use

Acquaer

Acquaer AUP033-5 manual

Pattfield Ergo Tools

Pattfield Ergo Tools E-GP 8030 Original operating instructions

Fultz Pumps

Fultz Pumps SP-400 manual

Seepex

Seepex BCSB Series Operating and assembly instruction

Pentair

Pentair Hydromatic S4BX Installation and service manual