Max Analog Output: once set the Max Input Level to +15dBu, in order to

identify the Maximum Output Level, need to move the Input Level

Potentiometer from the position 3, up to the position that is clipping the A/D

converter.

With +15dBu Input, the position of the Input Level Potentiometer at the limit of

the Input Clipping (notified when occurred by the RED CLIP LED ), is the position

6 of the Input Level grid of Fig A.

Once set, then, the Input Level Potentiometer to the position 6, in order to find

out the Max Output Level achievable with the CLP160, need to set the Output

Level Potentiometer to the position Max

The Max output Level that can be found is +9.8dBu, that is also indicated by the

Led Meters of the Front Panel, showing in fact the CLP160 OUTPUT LEVEL.

CLP160 Signal to Noise Ratio (S/N): from the condition got for the Max Analog

Output verification, can be go the S/N of the CLP160.

If, with the Max Output Level of +9.8dBu, the Input Signal Is removed,

measuring the output can be seen that the residual Ground Floor Noise drops to

-90.3dBu, which let us say that the S/N=(Max Output) – (GND Floor Noise) =

9.8dBu - (-90.3dBu) = 100dBu

Analog Bypass: de-pressing the “On/Off Process” button, the Analog Bypass

can be activated.

In this condition the CLP160 is bypassing the Digital section and connecting the

Analog Input to the Analog Output.

Here the Max Output is reaching the +11.4dBu with a GND Floor Noise of -

91.6dBu, bringing the S/N of the unit to 103dBu

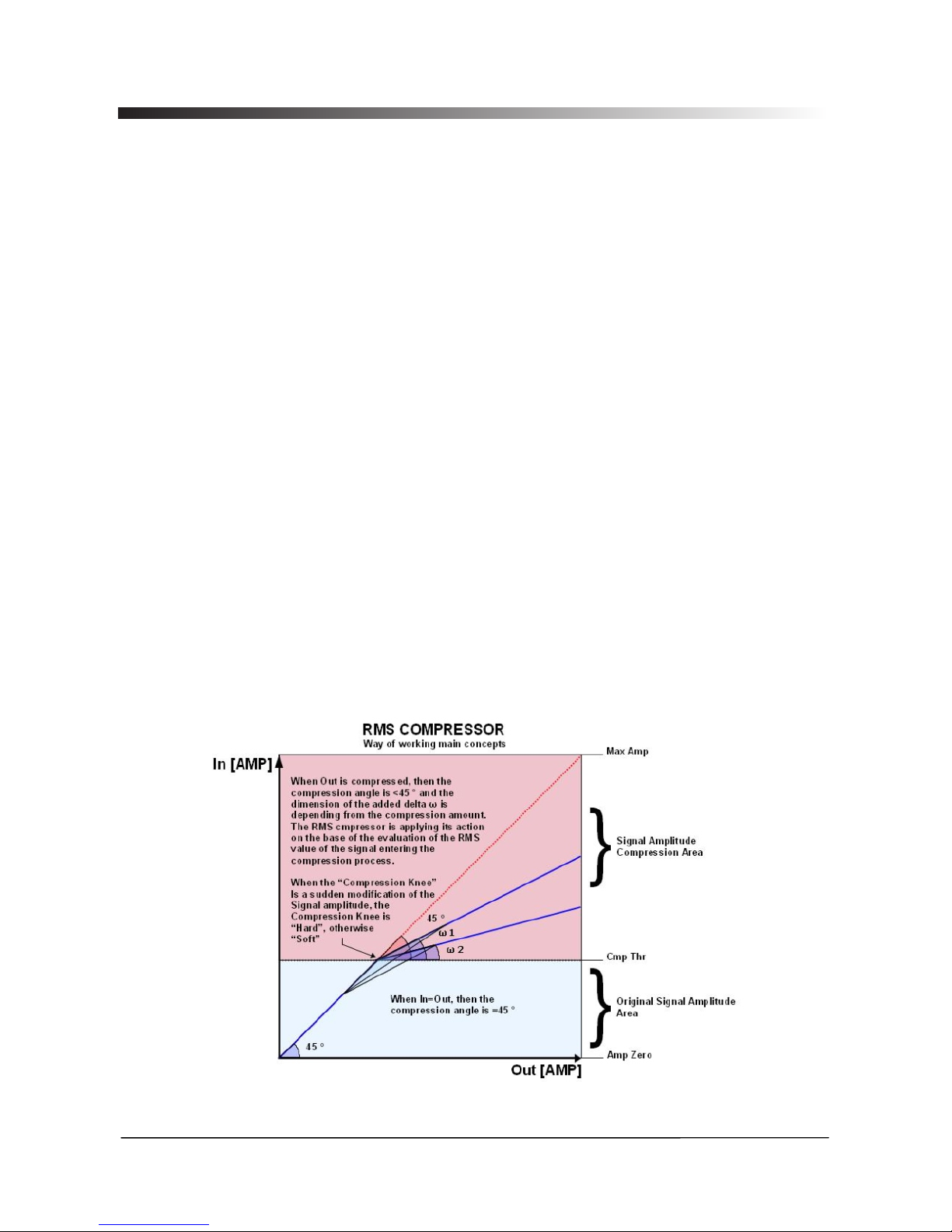

Set Input and Output Potentiometers for a 0dBu Input/Output path: in order

to evaluate the performances of the CLP160 RMS Compressor, we'll set a 0dBu

path, and to that one we'll refer the all measurement we'll show for making

understanding the Unit's way of working.

What anyway will be shown, will remain valid for any input level value there

where with the Input Level Potentiometer, the signal to the A/D will be adjusted

so to be close to the Clipping (notified by the RED CLIP Led).

In order to be on a 0dBu Input/Output path, when the Unit is in “Process

Bypass”, need from the previous condition to set the external Analog Input

Signal to 0dBu.

In order to get in Output also 0dBu, being at the maximum A/D Input level, need

to set the Input Level Potentiometer to 7 of the Grid of Fig A and the Output

Level Potentiometer to the position 7 of the Grid of Fig B.

The Output Led Meter will indicate 0dBu.

8