Marantz 5010 User manual

Other Marantz Cassette Player manuals

Marantz

Marantz SUPERSCOPE CD-320 Mounting instructions

Marantz

Marantz PMD420 User manual

Marantz

Marantz PMD511 User manual

Marantz

Marantz cp430 User manual

Marantz

Marantz CP230 User manual

Marantz

Marantz CR2020 User manual

Marantz

Marantz SUPERSCOPE CD-320 Mounting instructions

Marantz

Marantz SD-4051 User manual

Marantz

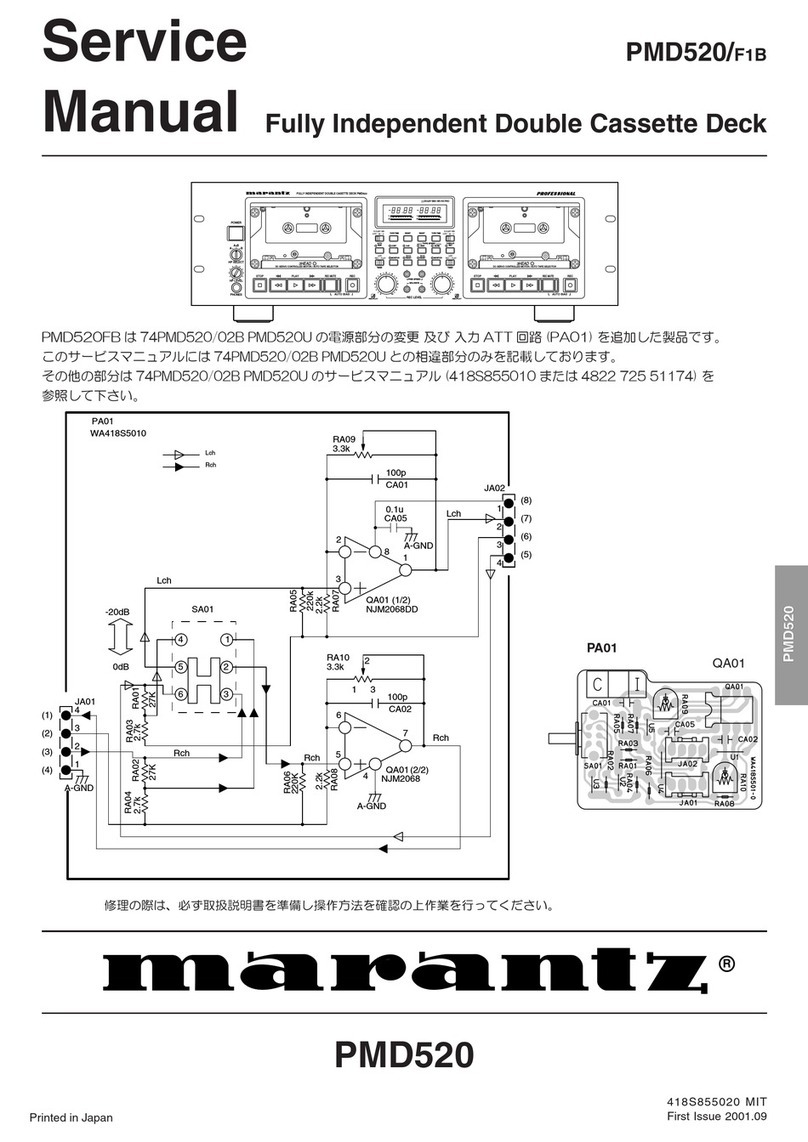

Marantz PMD520/F1B User manual

Marantz

Marantz SD4050 User manual

Marantz

Marantz SD8020 User manual

Marantz

Marantz Professional PMD520 User manual

Marantz

Marantz PMD222 User manual

Marantz

Marantz PMD510 User manual

Marantz

Marantz 5025 User manual

Marantz

Marantz SD530 User manual

Marantz

Marantz PMD505 User manual

Marantz

Marantz SUPERSCOPE CRS-2204 User manual

Marantz

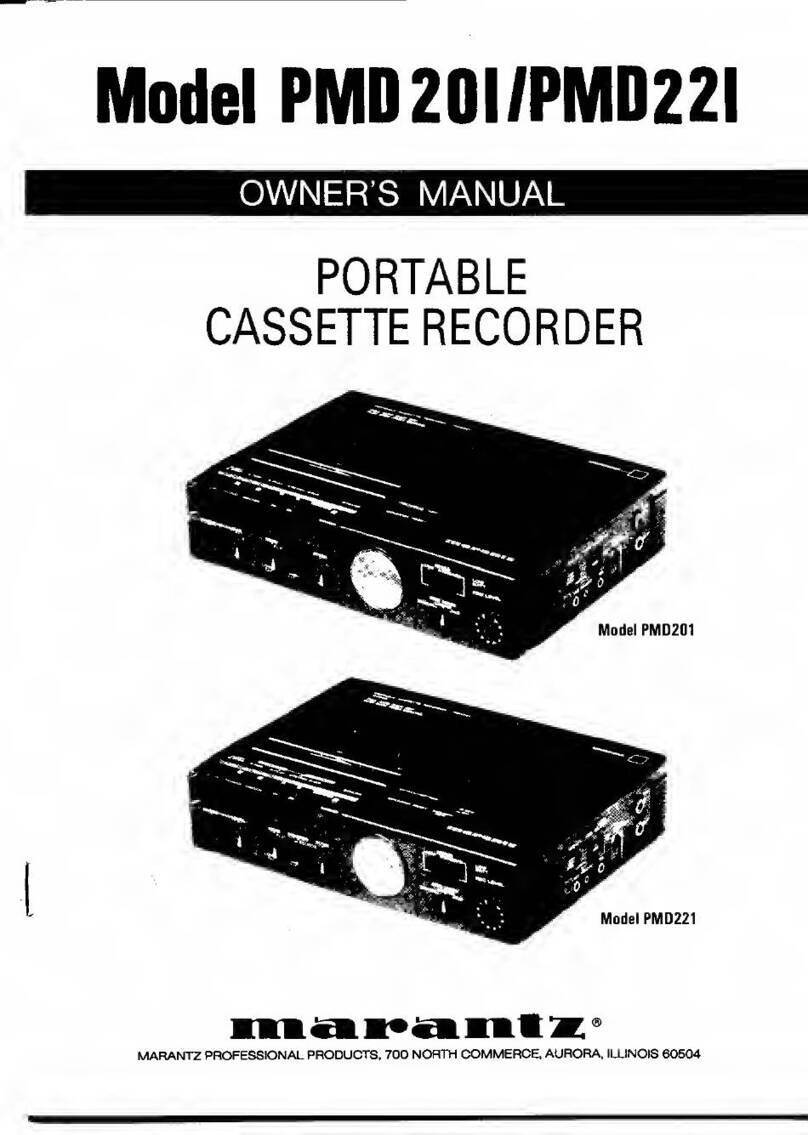

Marantz PMD201 User manual

Marantz

Marantz SD-4051 User manual

Popular Cassette Player manuals by other brands

Sony

Sony CFS-B15 - Am/fm Stereo Cassette Recorder operating instructions

Sony

Sony WMFS220 - Portable Sports AM/FM Cassette... operating instructions

Aiwa

Aiwa HS-TA21 operating instructions

Sanyo

Sanyo MCD-ZX700F Service manual

Aiwa

Aiwa CS-P77 Service manual

Sony

Sony Pressman TCM-465V operating instructions