Service Manual 1000615 Filtro Jug MF 1000616 Filtro Flask MF 02-05-2006 Page 6 of 9

TROUBLESHOOTING GUIDE

I you have any di iculty with your machine do not hesitate to call us. Some common aults

and solutions are highlighted in the table below.

Fault Possible Cause Action

T e mac ine is not working

and t e lamp in t e switc es

are not lig ting.

T e fuse in t e fuse box as

been triggered t e units loading

t e system too eavily

Replace/Reset t e fuse.

Connect t e unit to a more

suitably rated supply.

T e "Brewing" LED is on but no

water is flowing into t e filter

basket.

T e dry boil or t ermal fuse on

t e boiler is triggering and

olding t e boiler off.

Descale t e boiler.

or

Replace t e boiler.

T e "Descale" LED as turned

on.

T e units as been operating

for 300 cycles since t e last

descale

Descale t e boiler.

T e "Descale" LED stays on

even after a descale operation.

T e "Descale" counter as not

been reset

Reset t e "Descale" counter at

power-up.

T ere is water coming from

under t e mac ine

T e overflow is operating, t e

tank is being over-filled.

Use mac ine to empty tank.

[N.B. a full tank is about 2.3L]

T e coffee is too weak. Not enoug ground coffee as

been used in t e filter.

T e spray ead disk is scaled

up or dirty and t e flow in

uneven.

Increase t e amount of coffee.

Remove t e spray ead disc

and clean.

T e coffee is too strong. Too muc ground coffee as

been used in t e filter.

Reduce t e amount of coffee.

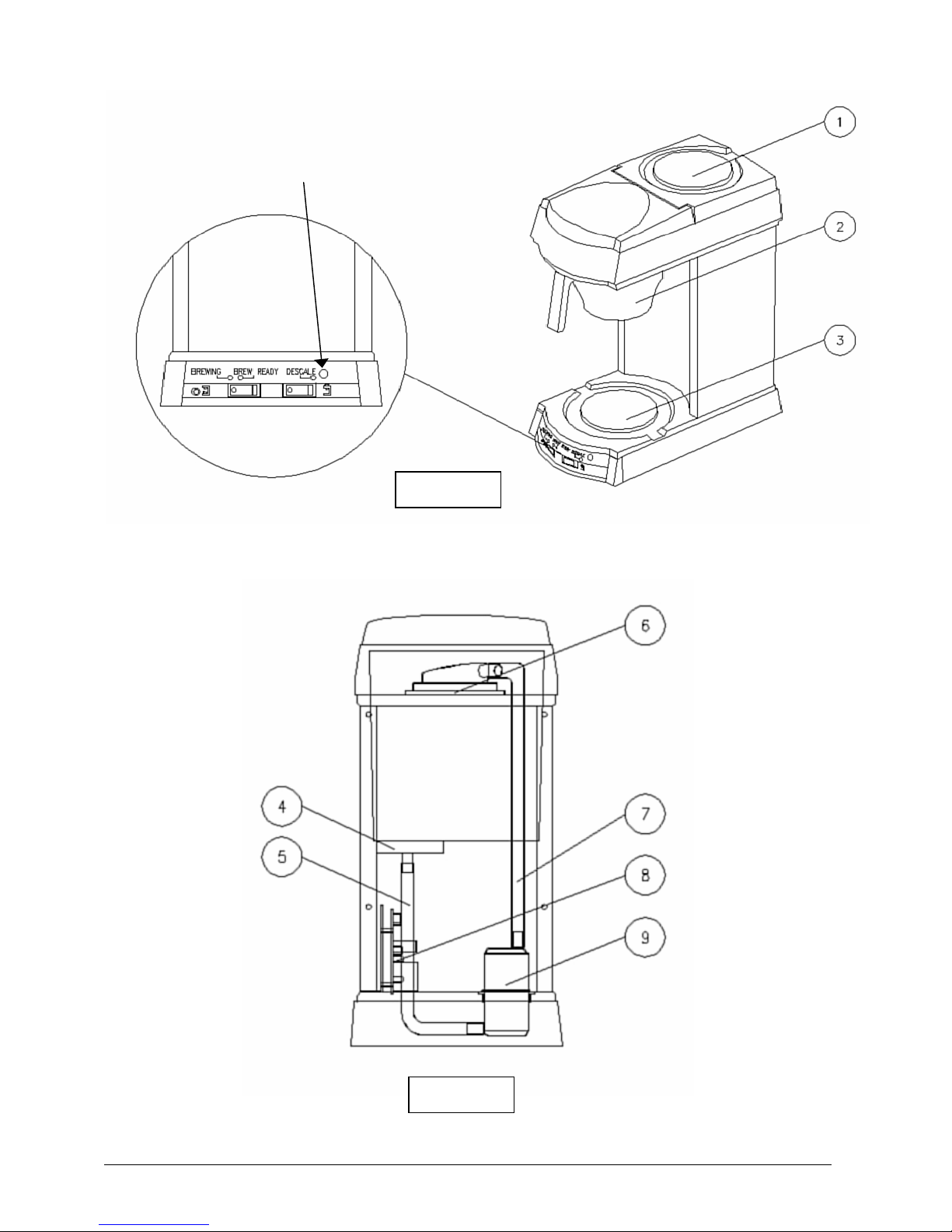

SPARE PARTS LIST

Part

Number

Description

1000615

1000616

Reference

(see Figs 1& 2 )

2300072 Basket FILTRO

2

1801196 Spray ead Rose FILTRO

6

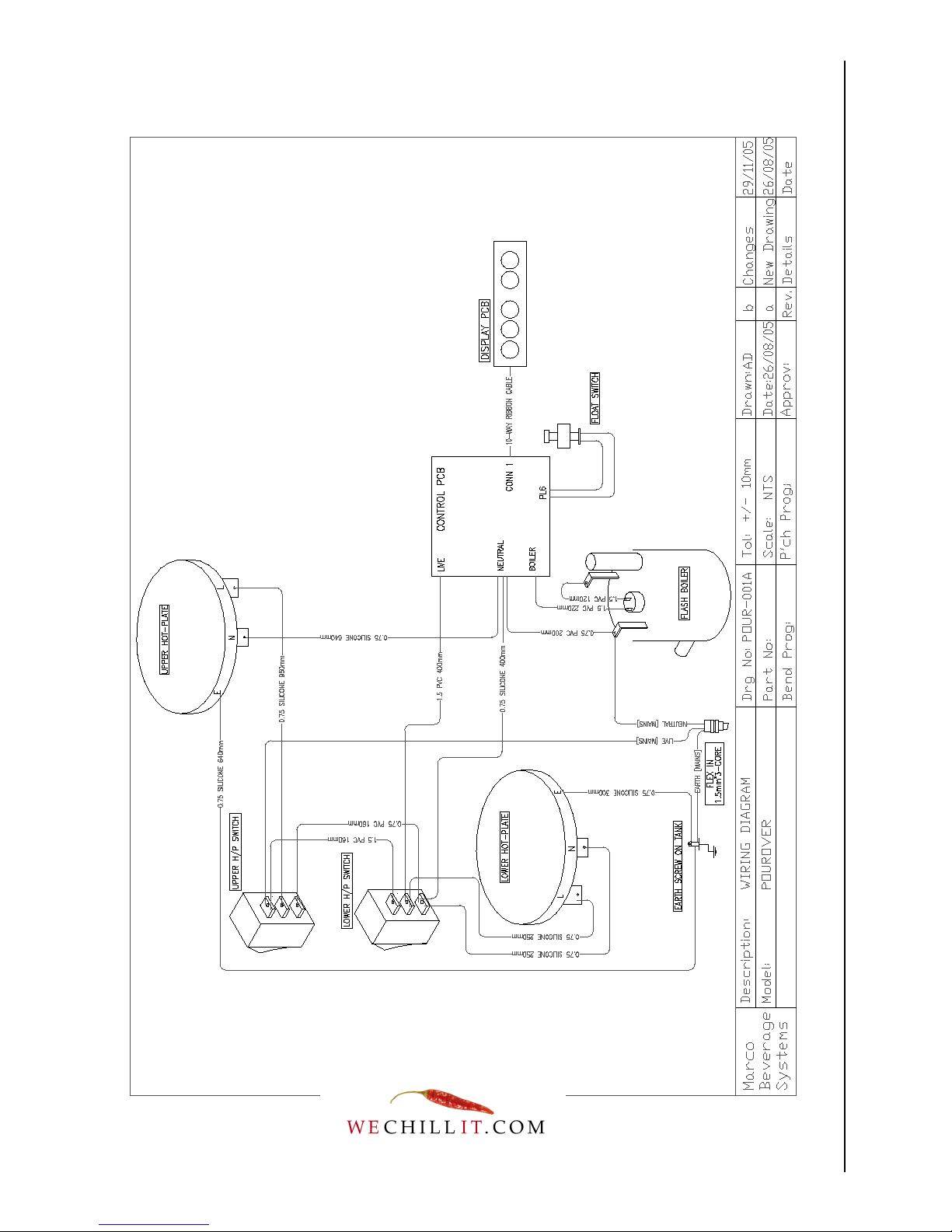

1600341 P.C.B. FILTRO Control

8

1600342 P.C.B. FILTRO Display

1501058 Flas Boiler 230V 2100W

9

1800643 Hose Silicone FILTRO Flask Hot side

7

1800644 Hose Silicone FILTRO Flask Cold side

5

1800641 Hose Silicone FILTRO Jug Hot side

7

1800642 Hose Silicone FILTRO Jug Cold side

5

1501076 Float switc FILTRO

4

1500925 Hotplate FILTRO c/w PTC

1,3

1500927 Hotplate FILTRO – plate w/o PTC

1,3

1500926 Heater PTC FILTRO

1,3

8000200 Filter Paper - FILTRO

8000270 ScaleKleen 200g

1700173 Airpot Lever 2.2L

1700170 Jug Glass Coffee 1.8L