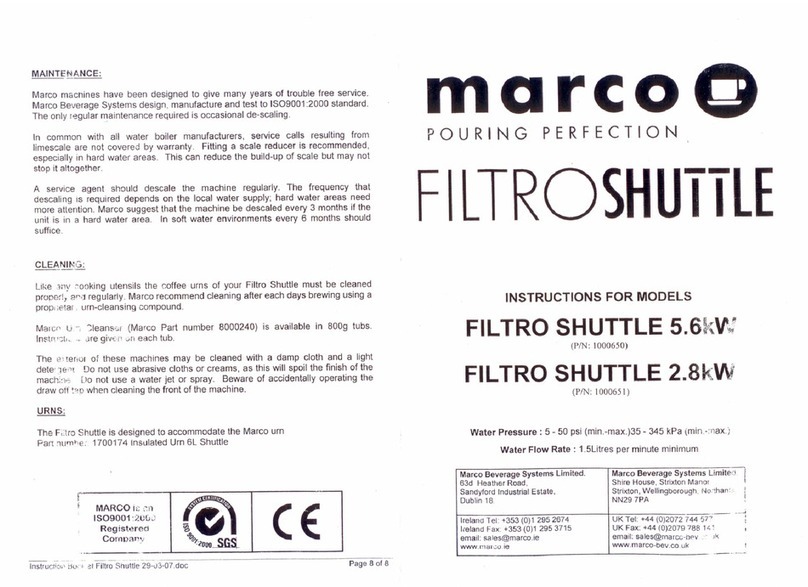

5. START UP

Turn the water on at the stop valve and switch the power on at the plug. Press the

POWER ON button at the front of the machine. A red light next to the button will

illuminate and the machine will start to fill.

Note: The machine will not heat until the water has reached the low level probe.

When the low-level probe is reached the element is switched on this water is heated to the

pre-set temperature (93 –94.5°C). The machine takes in another small body of water,

while continuing to heat. This method of staggered filling (heat-fill cycle) ensures that the

temperature in the tank remains within 3 degrees of set temperature. This heat-fill cycle

continues until: a) the water level reaches the high level probe and

b) the water temperature reaches the pre-set temperature as above.

This may take up to 1 hour.

Note: When the level of water is at a safe height above the low level, the green

READY TO BREW light illuminates. The machine is not full at this level. A brew

can be selected, but no hot water is available. Unless a brew is selected, the full

quantity of hot water should be available within 25minutes of reaching this level.

6. OPERATION

The machine is ready to brew Coffee and 10 pints of Hot Water is available for

immediate draw-off when the machine is full and up to temperature.

The machine has one large water tank, with an urn recessed into it. When a brew is

selected, hot water is pumped from the tank up to the sprayhead and into the filter basket.

The coffee runs out of the filter basket into the urn. Since the water tank surrounds the

urn, the brewed coffee is kept at temperature.

The machine works on a heat fill cycle which means that the temperature in the tank does

not drop by more than 3 degrees. The machine will only allow small amounts of cold

water into the tank, while continuing to heat to ensure that the temperature does not drop

too low.

If more hot water is used than the machine can recover (0.48l/min), the amount of water

in the tank decreases. If the full quantity of Hot Water is drawn off, the machine will take

approximately 25min to recover back up to the high level probe.

Note: a brew can still be selected when no Hot Water is available out of the tap. This

is due to a buffer of hot water beneath the level of the ‘hot water stand pipe’ inside

the tank. This should preferably be a half brew rather than a full brew to ensure

shorter recovery times. Drawing off Hot Water while brewing Coffee should not

affect the quality of the brew.

When the level has dropped to a point where a brew cannot be completed, the ready to

brew light goes out and a brew cannot be selected. A 3rd level sensor probe, the ‘Brew

Level Probe’ controls this level. After a recovery period (up to 20min), the machine will

be ready to brew once again. Note: a longer recovery is required before any substantial

amount of Hot Water can be drawn off.