Section 1

I GENERAL INFORMATION

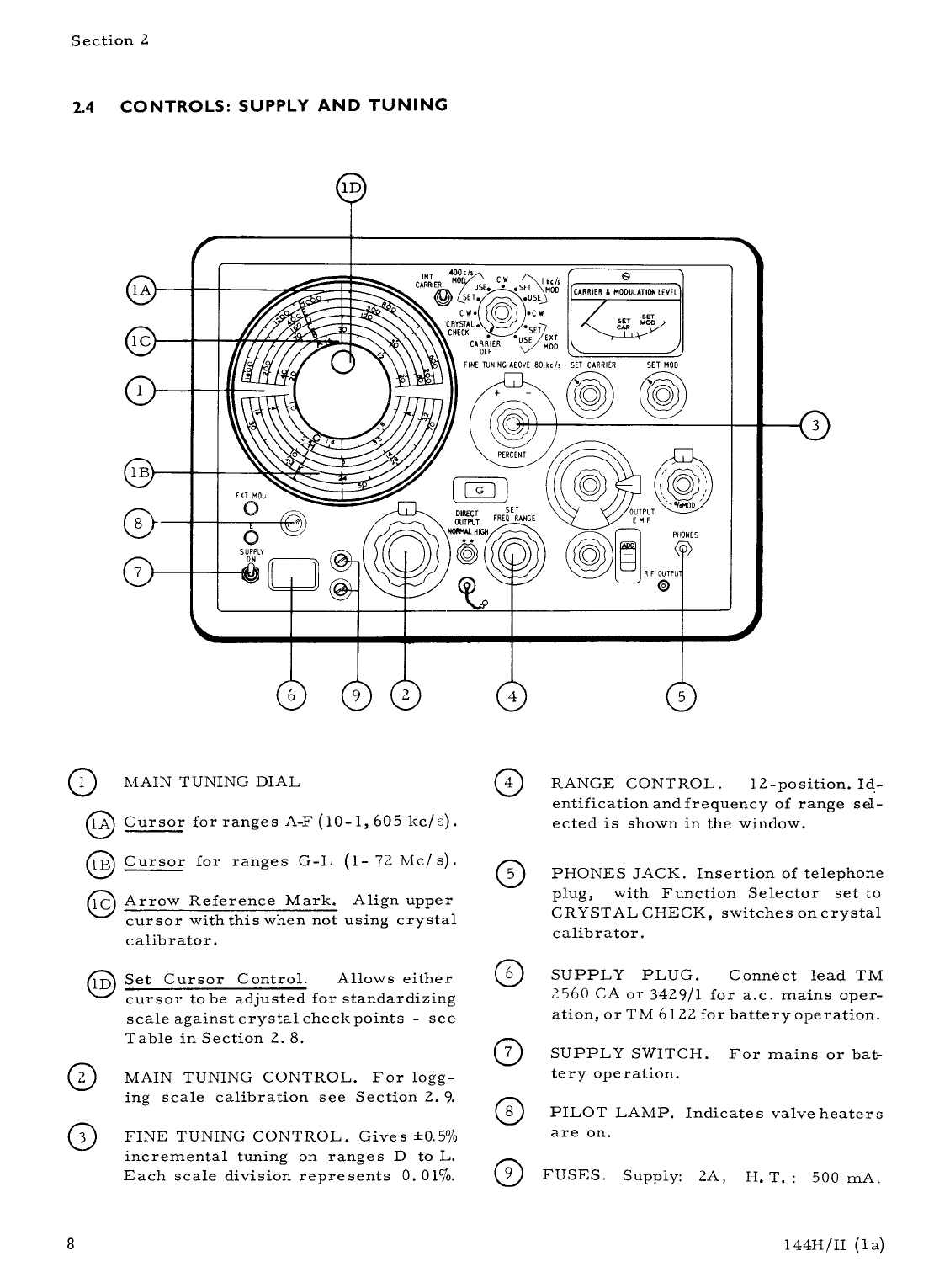

1.1 FEATURES

The TF 144H series of signal gener-

ators give c.w, and a. m. outputs suitable

for the standard measurements and tests on

equipment operating in the m. f. , h. f. , and

lower v. h. f. bands. Their good frequency

stability and high-discrimination tuning are

of particular advantage in testing narrow-

band communication receivers.

Each generator covers 10 kc/s to 72

Mc/ s in twelve ranges. Eight of these ran-

ges follow a straight-line frequency law and

have a frequency cover of 2:1; the remain-

ing four have a slightly greater range and

one of them covers the medium-wave broad-

cast band.

A large effective scale length

is provided on the main tuning dial whichhas

separate hand-calibrated scales for each

range. Its discrimination is such that a 2%

frequency change on any band occupies more

than a quarter of an inch of scale length.

Frequency accuracy is ±1%, but for greater

accuracy there is a built-in crystal calibrator

which gives at least 90 crystal check points

throughout the twelve ranges.

An 8:1 reduction drive from the main

tuning control enables easy and precise adj-

ustment to be made, and a linear logging

scale with 100 divisions attached to the main

tuning control facilitates interpolation be-

tween any of the main-scale divisions.

In

addition to the logging scale, a fine tuning

control is provided which is operative above

80 kc/ s and enables incremental frequency

adjustments to be made, with complete

freedom from backlash, up to ±0. 5% of the

frequency in use.

Modulation can be applied from an inter -

nal 400-c/ s to 1000-c/ s oscillator or from

an external source. In both cases, depth is

variable up to 80% over most of the frequency

range.

There are two r.f. signal outlets. One

supplies an output e.m.f. switchable between

2 and

2.

75 volts (monitored by the meter) at

very low impedance while the other supplies

a variable e.m.f. between 2 µV and 2 volts via

coarse and fine 50-ohm attenuators; the out-

put range may be extended down to 0.2 µV by

using the 20-dB Attenuator Pad accessory.

A system of automatic level control keeps

the carrier level constant throughout wide

frequency changes.

Designed for operation from either a. c.

mains or battery supplies the instrument is

available in forms suitable for bench or

rack mounting, as detailed below.

1.2 STANDARD AND SERVICES VERSIONS

TF 144H/4 and TF 144H/4R are the

standard bench- and rack-mounting models.

The versions with suffix 'S' are Services

types which are distinguished from the stan-

dard models by a sealed round meter, a

Plessey Mk. IV mains supply plug, and acc-

essories supplied.

Standard Models

TF 144H/4 : Bench mounting

TF 144H/4R : Rack mounting

Services Models

TF 144H/4S : Bench mounting.

No acces-

sories. Joint-Service Ref. No.

CT 452A.

TF 144H/6S : Bench mounting. With acces-

sories. Ref. No. CT 452A Set.

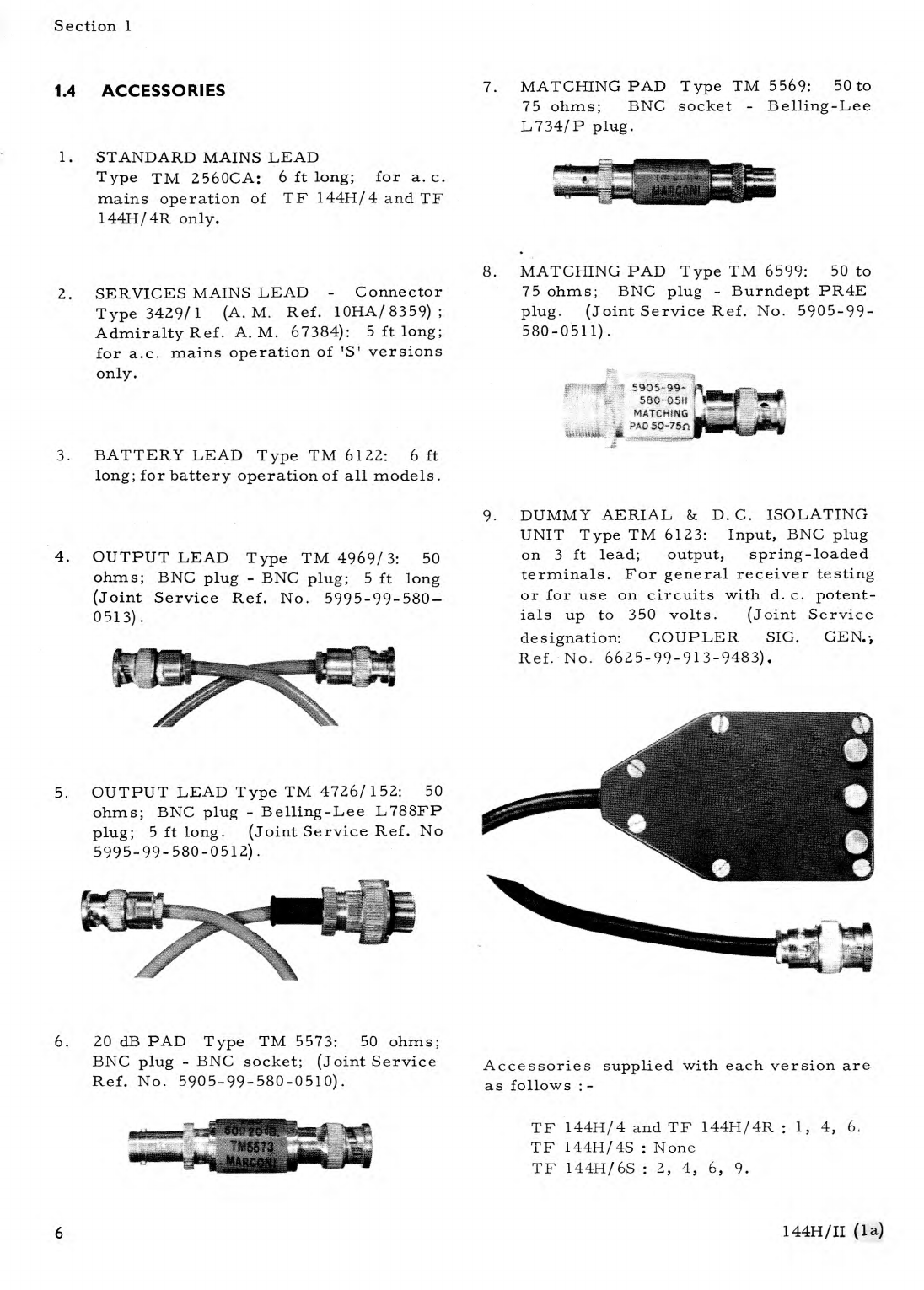

The accessories supplied and available

are described in Section 1.4.

144H/II (1)

3