6

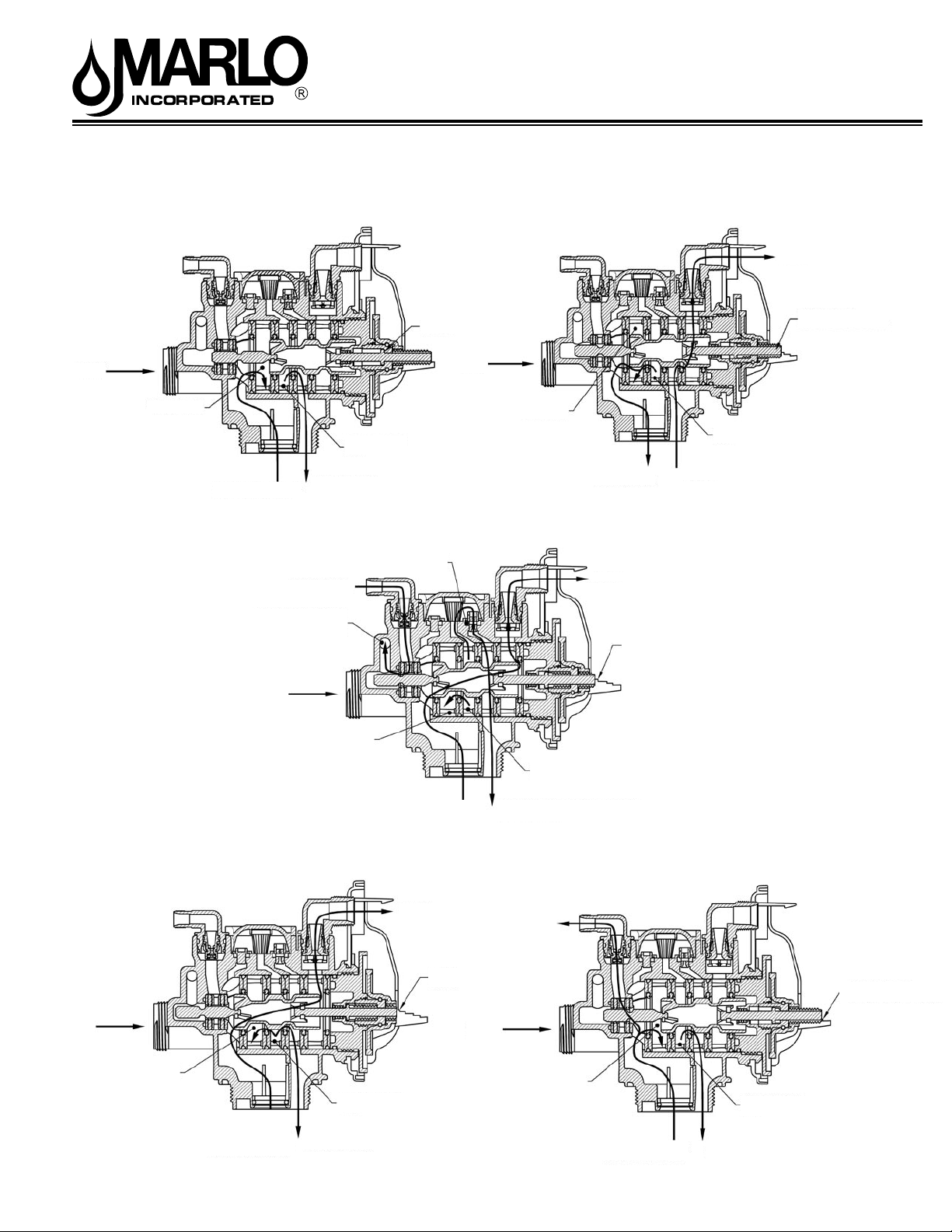

Control Valve Function and Cycles of Operation

This glass filled Noryl1 fully automatic control valve is designed as the primary control center to direct and regulate

all cycles of a water softener or filter. When the control valve is set up as a softener, the control valve can be set

to perform down flow or up flow regeneration with the proper piston. When the control valve is set up as a filter,

the control valve can be set to perform down flow regeneration or simply backwash. The control valve can be set

to regenerate on demand (consumption of a predetermined amount of water) and/or as a time clock (passage

of a particular number of days). The control valve can be set so that the softener can meet the Water Quality

Association (WQA) or NSF International efficiency rating.

The control valve is compatible with a variety of regenerants and resin cleaners. The control valve is capable of

routing the flow of water in the necessary paths to regenerate or backwash water treatment systems. The injector

regulates the flow of brine or other regenerants. The control valve regulates the flow rates for backwashing,

rinsing and the replenishing of treated water into a regenerant tank, when applicable.

The control valve is designed to deliver high service (27 gpm @ 15 psig) and backwash (27 gpm @ 25 psig) flow

rates when the bypass has straight fittings and a 1.050” distributor. The control valve uses no traditional fasteners

(e.g. screws), instead clips, threaded caps, nuts and snap type latches are used. Caps and nuts only need to

be firmly hand tightened because radial seals are used. Tools required to service the valve include one small

blade screwdriver, pliers and a pair of hands. Disassembly for servicing takes much less time than comparable

products currently on the market. Control valve installation is made easy because the distributor tube can be cut

1/2” above to 1/2” below the top of the tank thread. The distributor tube is held in place by an

o-ring seal and the control valve also has a bayonet lock feature for upper distributor baskets.

The transformer power pack comes with a 15-foot power cord and is designed for use with the control valve. The

transformer power pack is for dry location use only. The control valve remembers all settings for two hours if the

power goes out. After two hours, the only item that needs to be reset is the time of day; all other values are stored

in the memory. The control valve does not need batteries.

Table 3 shows the order of the cycles when the valve is set up as a softener. When the control valve is used as

a down flow softener, two backwashes always occur. When the control valve is used as an up flow softener, only

one backwash occurs after brining. The installer has the option of having the regenerant refill after the rinse cycle

or have the regenerant prefill before regeneration. If the installer chooses to have the regenerant prefill before

regeneration, the prefill starts two hours before the regeneration time set. During the 2-hour period in which the

brine is being made, treated (softened) water is still available. For example: regeneration time = 2:00 A.M., prefill

option selected, downflow softener. Fill occurs at 12:00 A.M., start of backwash cycle occurs at 2:00 A.M.

1 - Noryl is a trademark of General Electric

Table 3

Regeneration Cycles

1st Cycle: Backwash Normal

2nd Cycle: Regenerate

3rd Cycle: Backwash Normal

5th Cycle: Rinse

6th Cycle: Fill

8-198 R1

“CMP & C” Series Automatic Water Conditioners