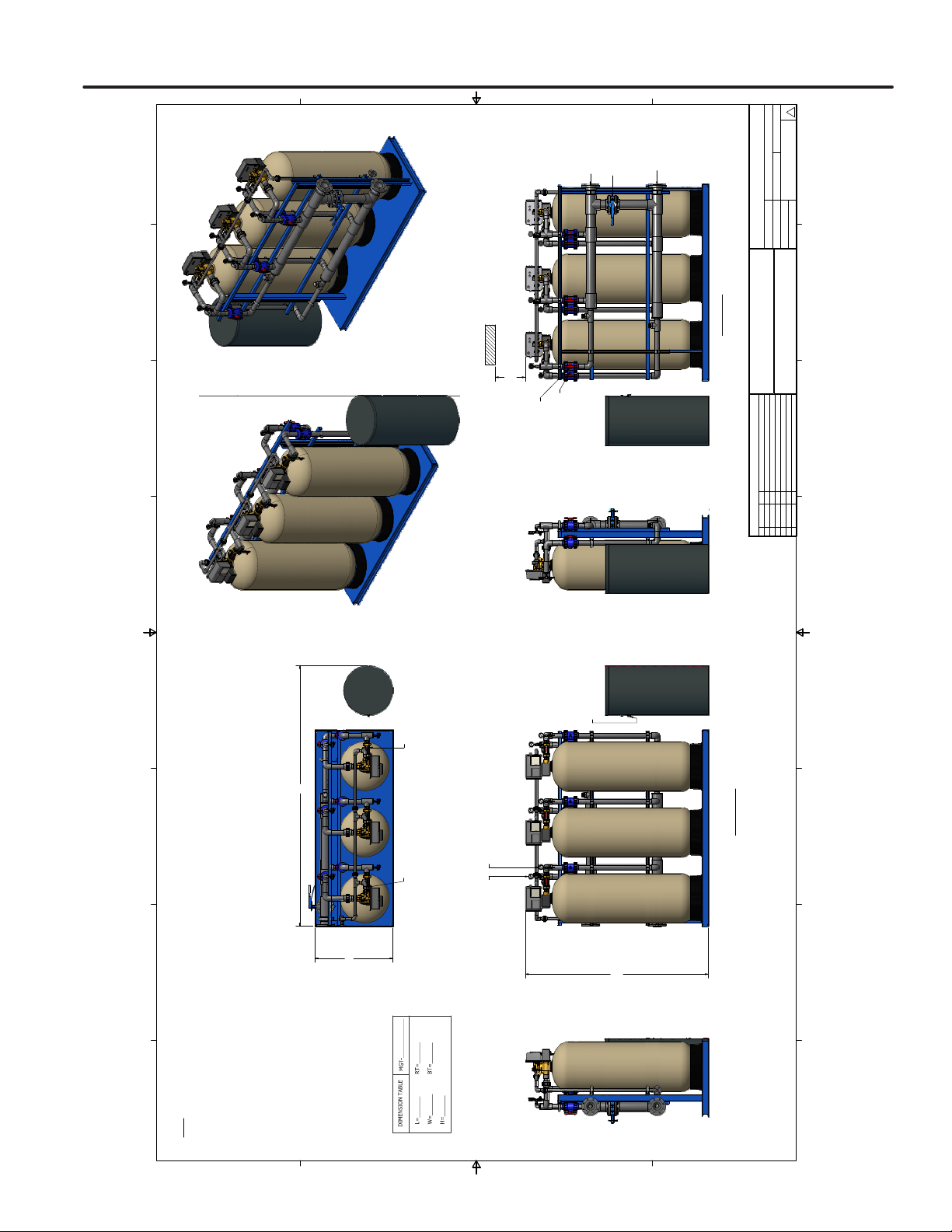

MGT 2” 60M–600M NXT2 SYSTEM 14 DEMAND

TABLE OF CONTENTS

SYSTEM INFORMATION

Product Warranty...........................................................................................................................................................1

General Arrangement Drawings ....................................................................................................................................2

Dimension Chart ...........................................................................................................................................................6

Specication Chart .......................................................................................................................................................7

INSTALLATION

General Information.......................................................................................................................................................8

Loading Softener ..........................................................................................................................................................9

Mounting Control Valve ................................................................................................................................................9

Brine Tank Installation .................................................................................................................................................10

Mounting Water Meter ................................................................................................................................................. 11

Network Communication Cables/Connections ............................................................................................................ 11

Power Supply Wiring ...................................................................................................................................................12

Connection Piping Installation .....................................................................................................................................12

OPERATION

Timer Display Features ...............................................................................................................................................13

System Operation........................................................................................................................................................15

Timer Operation...........................................................................................................................................................17

Start-Up Procedures....................................................................................................................................................18

User Mode Programming Flow Chart..........................................................................................................................19

Batch Size Calculation.................................................................................................................................................20

Diagnostic Mode Flow Chart .......................................................................................................................................21

Master Programming Flow Chart.................................................................................................................................22

Master Programming Guide ........................................................................................................................................24

Flow Diagrams.............................................................................................................................................................25

Wiring Diagram............................................................................................................................................................31

MAINTENANCE

Powerhead Assembly .................................................................................................................................................32

NXT2 Timer Assembly.................................................................................................................................................34

Control Valve Assembly...............................................................................................................................................35

Brine Injector Assemblies ...........................................................................................................................................37

Meters and Flow Sensors ...........................................................................................................................................40

Brine Tank Assemblies ...............................................................................................................................................45

Service Assemblies ....................................................................................................................................................49

Troubleshooting...........................................................................................................................................................50