CHANGING FROM “B” to “C” size blades

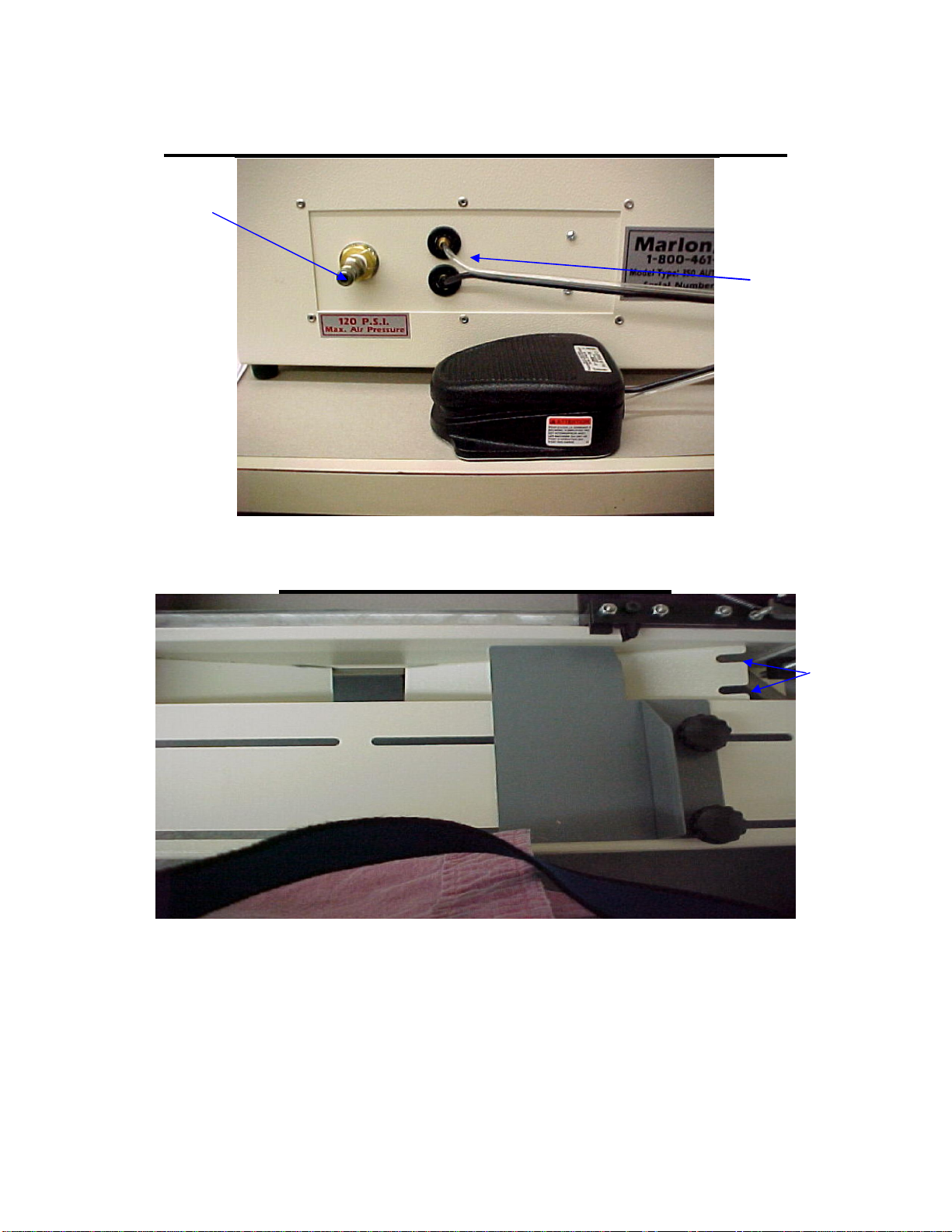

1.)Disconnect the air supply from Marlon 350.

2.)Remove top cover from machine.

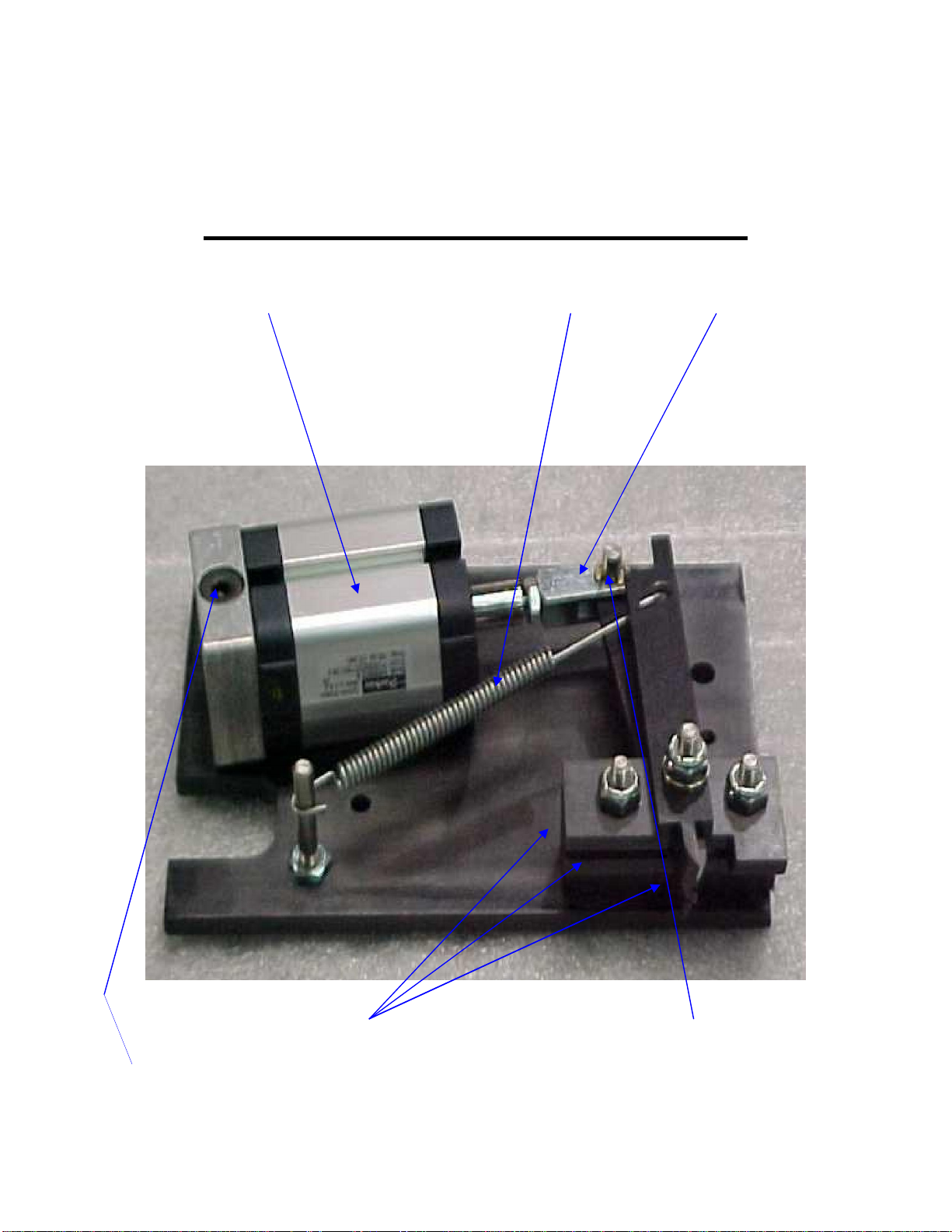

3.)Unhook the springs from the studs on both sides.

4.)Remove the three 10-24 nylock nuts from each side.

5.)The left clamp blade is now free.

6.)Remove the right anvil blade by lifting it straight up.

7.)Remove the left forming blade by lifting it straight up.

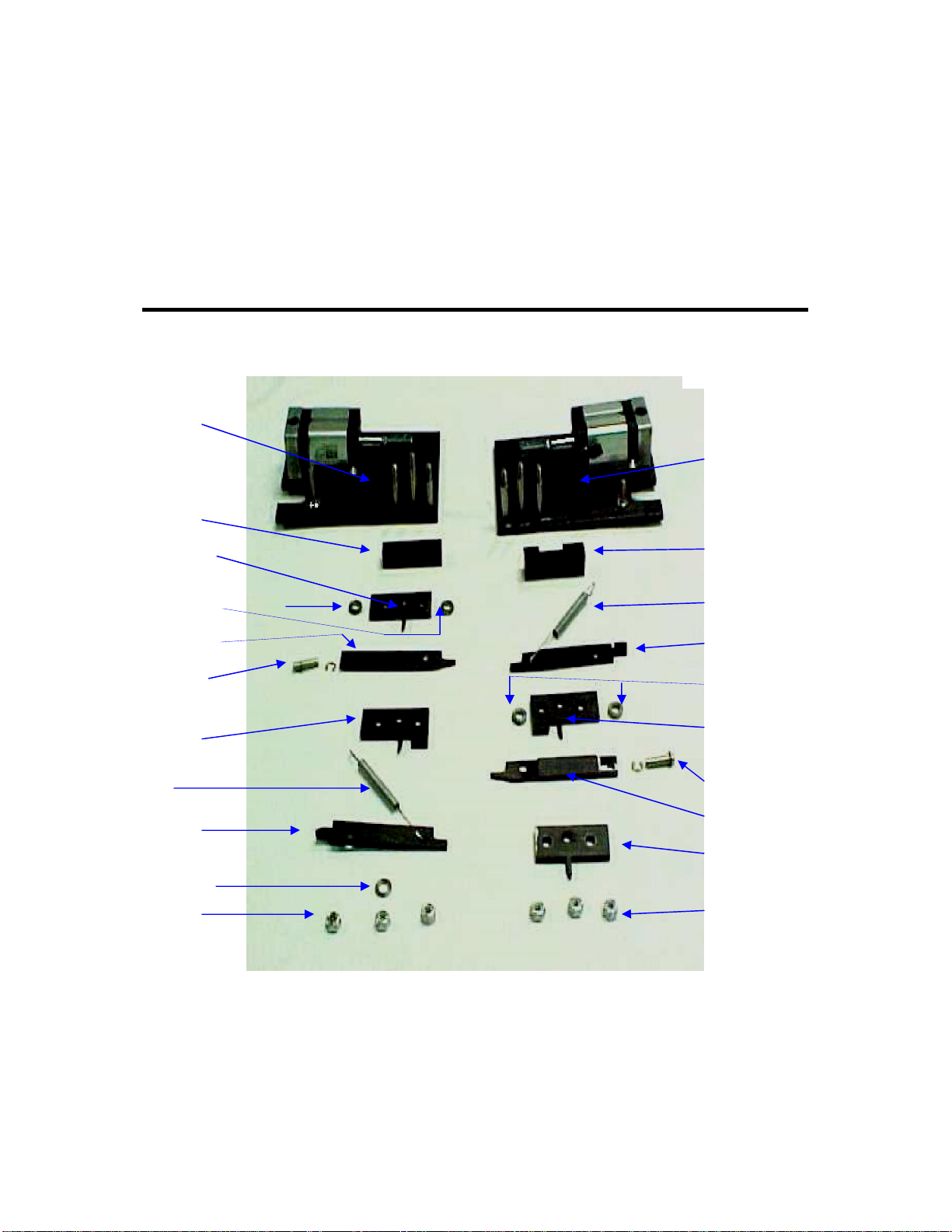

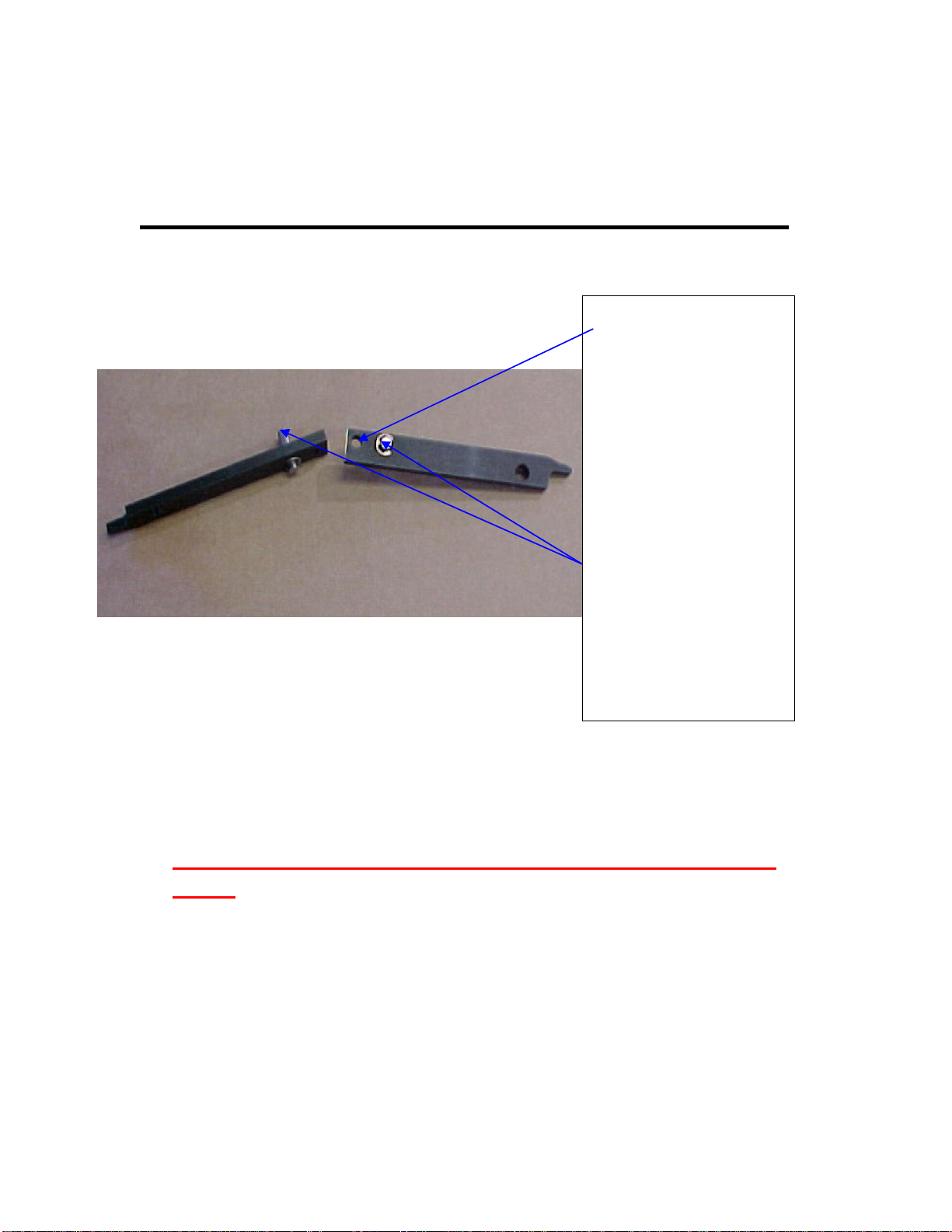

8.)Detach the right cutter blade from the clevis. (Use a straight

blade screwdriver to pry the top E clip off of the clevis pin.

Slide the clevis pin out of the clevis; the right cutter blade is

now free.)

9.)Remove the two126” B-size spacers from each side.

10.) Remove the right forming blade by lifting it straight up.

The right clamp blade is nowfree.

11.) Detach the left cutter blade from the clevis. (See step 8

for details.)

12.) Leave the left anvil blade on, because it’s used in all

three setups.

13.) Change the air cylinder position on both sides by

unscrewing the air cylinder mounting bolt (shown on page

5) now move the air cylinder to its correct hole position and

tighten the air cylinder mounting bolt. (See picture on page

10 for details.)

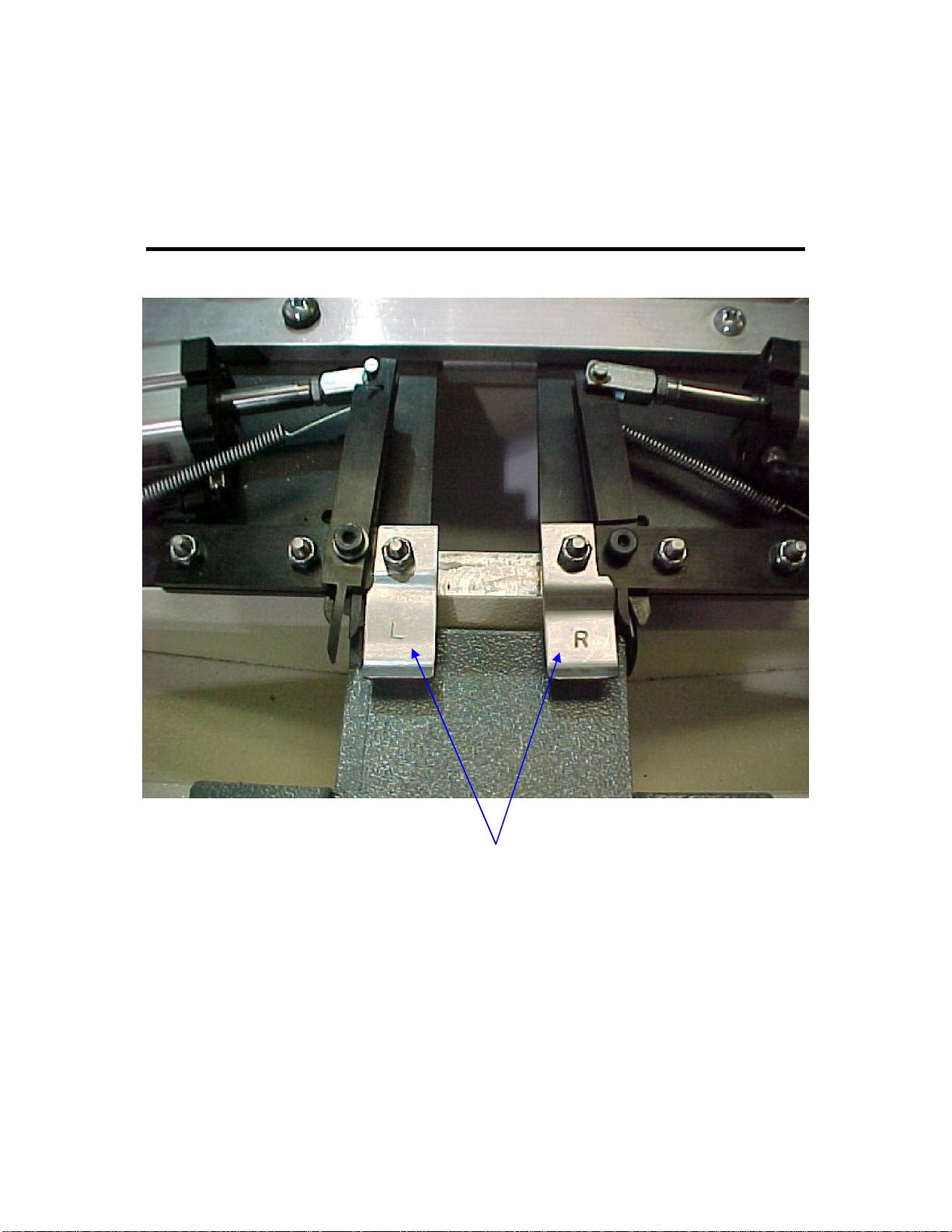

14.) Reassemble the cutter blade assemblies in reverse order

using the correct color-coded parts.

15.) Note: No spacer is used on the left-hand center stud

when using the C-size blade configuration.