Page 3

SYSTEM

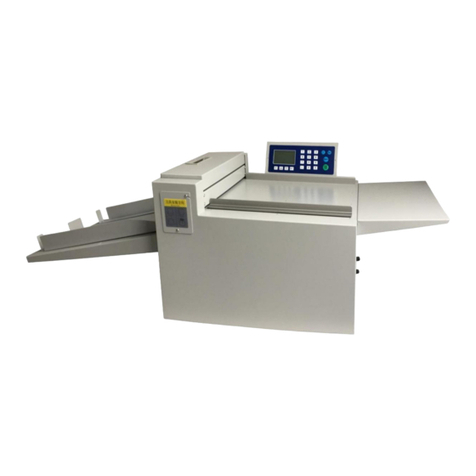

AutoCreaser 50

INTRODUCTION

AutoCreaser 50

The Morgana Autocreaser 50 is a fully automatic suction feeding creasing

system designed for use with both conventional litho and digital printers.

The feed on the Autocreaser 50 can also be manually operated for use with

heavy stock, very small or very large sheets, embossed or even irregular

sheets.

The Autocreaser 50 is capable of creasing sheet sizes to a maximum of

700mm x 500mm (27.5” x 19.7”) and weights in excess of 350gsm.

The minimum sheet size when the machine is used in automatic mode is

140mm x 210mm (5½ “x 8½”).

Up to sixteen creases can be programmed to a single sheet.

The crease is programmed from the leading edge of the sheet using the

controls on the front panel.

A minimum distance between creases is 0.1mm

The Autocreaser 50 has up to nine available memory addresses for

programmed creasing operations.

The blade and anvil are mechanically controlled over their entire length

and can be adjusted to accommodate various weights of media.

IMPORTANT

16° C and 27° C Maximum

The operating environment should be controlled to a temperature between