CAUTION!

Because the valve is spring closed (aided by

pressure), the handle can snap down with

considerable force when closing. Keep hands and

fingers away from the handle as it closes.

To Close an Open Valve:

Manually pushing the handle to the "closed" position

will close the valve.

From a remote location, pulling on the remote cable

release or exhausting pneumatic pressure from the

ME980 latch will retract the latch plunger allowing

the ME980 to close. If emergency conditions cause

the fusible element to reach a temperature of 212°F

(100°C), the fusible element, which attaches the

handle to the shaft, melts and allows the valve to

close automatically.

Installation

Shutoff Direction

The valves can be placed in a line used either for

filling or withdrawing from the storage tank (or

both). The valve shall be installed in the fixed piping

between a storage tank and the transfer hose

connection to shut off flow from the tank towards

the hose.

WARNING!

The ME980 valves are spring closed (aided by

pressure) and shutoff flow in one direction only.

THE NAMEPLATE FLOW ARROW SHOWS FLOW

DIRECTION FOR VALVE SHUTOFF. The arrow shall

point to the hose connection. Improper flow

direction will not shutoff flow through the line.

The valve can be installed in vertical piping with the

flow arrow pointing in the desired flow direction for

valve shutoff. In some cases the normal flow through

the valve may be opposite the shutoff direction (like

a back check valve).

Fusible Element Location

A fusible element that will close the ME980 shall be

located within five feet of the hose connection. If the

ME980 is placed within five feet of the hose

connection, this requirement is met. If not, an

additional fusible element must be provided near

the hose coupling which will activate a remote

release.

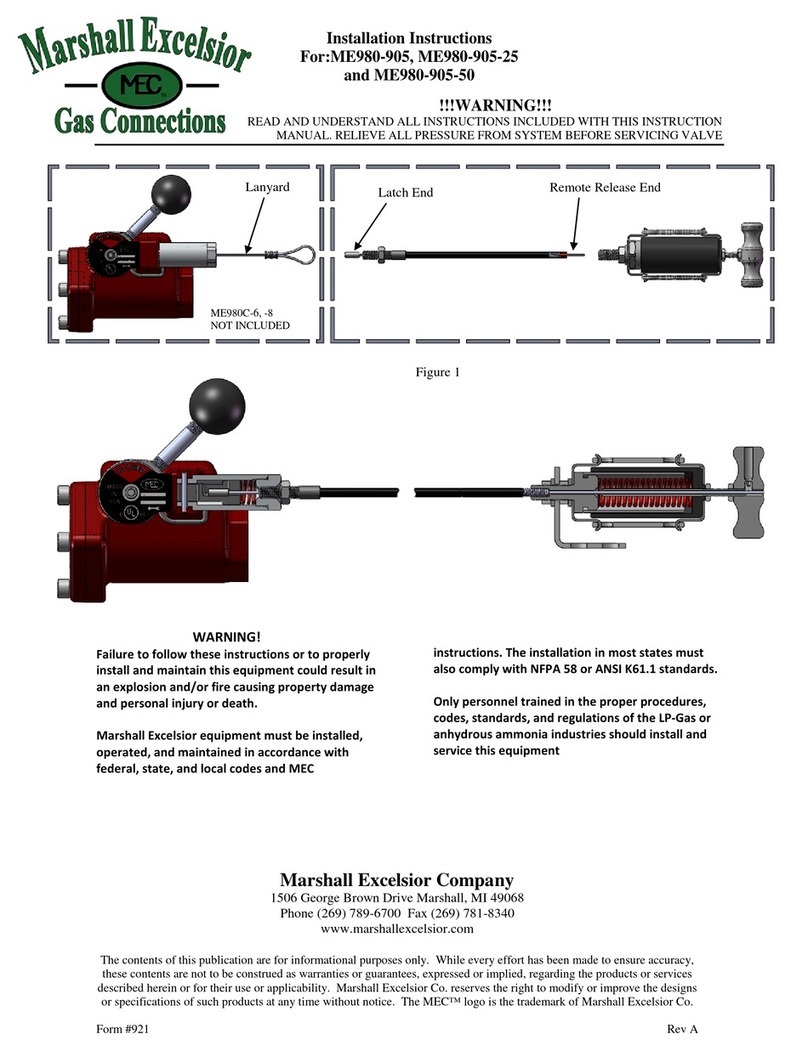

Remote Release Installation

In all installations a remote release shall be

connected to the latch on all emergency valves at

the bulkhead. The remote release has to extend to a

place where it can be easily reached to close the

ME980 valve(s) in the event that an emergency

makes the valve(s) inaccessible. The remote release

shall shutdown all emergency valves when activated.

Remote release activation may be by cable or

pneumatic actuation.

PNEUMATIC RELEASE CONNECTION

1. Attach the remote air source to the cylinder

end with appropriate supply tubing and

valving. A regulated air supply of 30 to 70

PSIG to the ME980 pneumatic release

cylinder is required for proper operation.

NOTE: Nitrogen may be used as a pressure

source.

CAUTION

Possible hand and finger pinch points

between closing ME980 handle and

latch block. Handle closes quickly and

with extreme force. Keep hands and

fingers away from handle as it closes.

2. Test the remote release and ME980

operation. Open the valve. Valve must

engage latch and stay open. HANDLE AND

VALVE MUST QUICKLY "SNAP" CLOSED

when (a) air pressure is exhausted from

ME980 latch (b)remote cable release is

pulled (if applicable), and (c) the handle is

manually pushed closed from the open

position.

WARNING!

All open ME980 Emergency Valve(s) attached to the

remote pneumatic release system must properly

close when air pressure is exhausted from the

system. Remote release controls must quickly

exhaust pressure from the supply line to close

emergency valves.