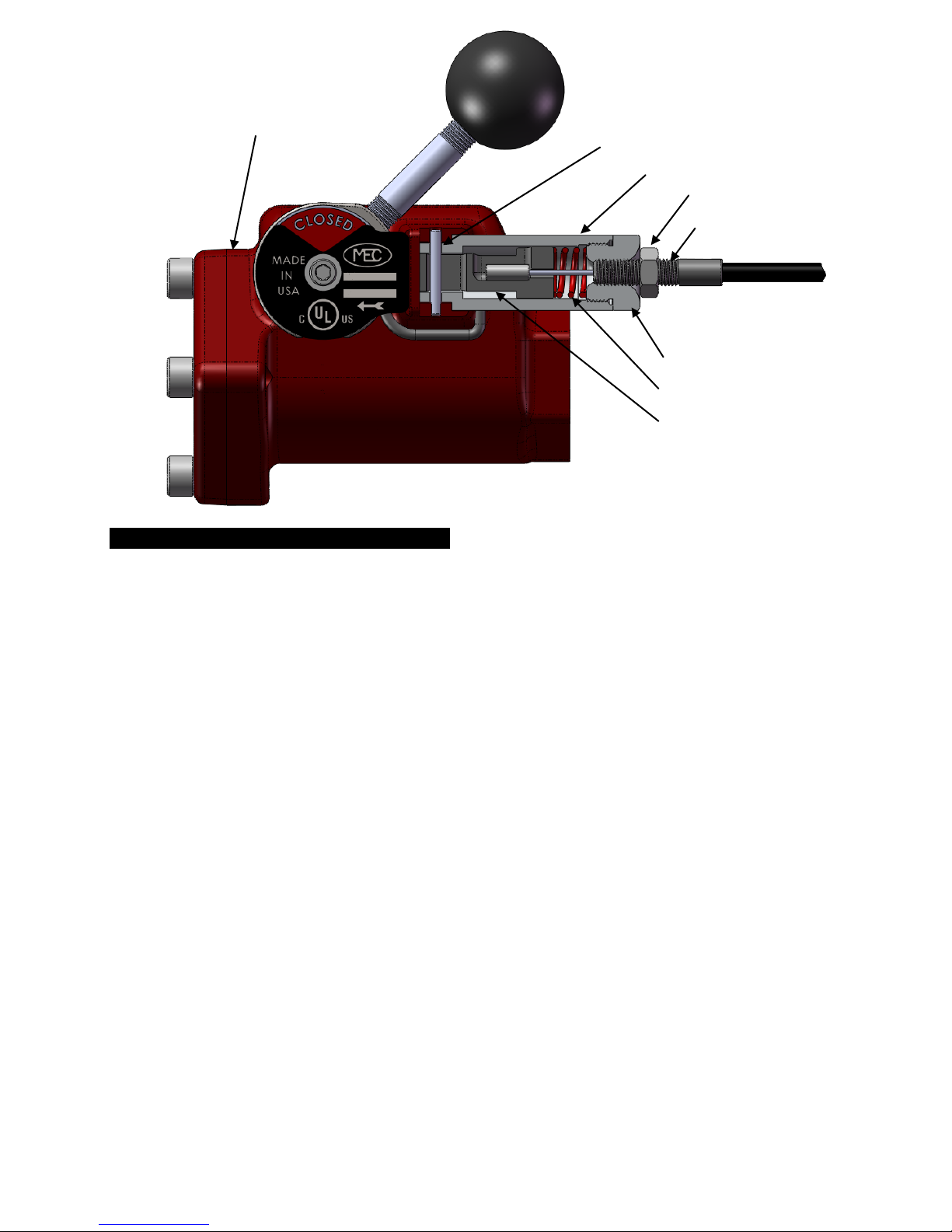

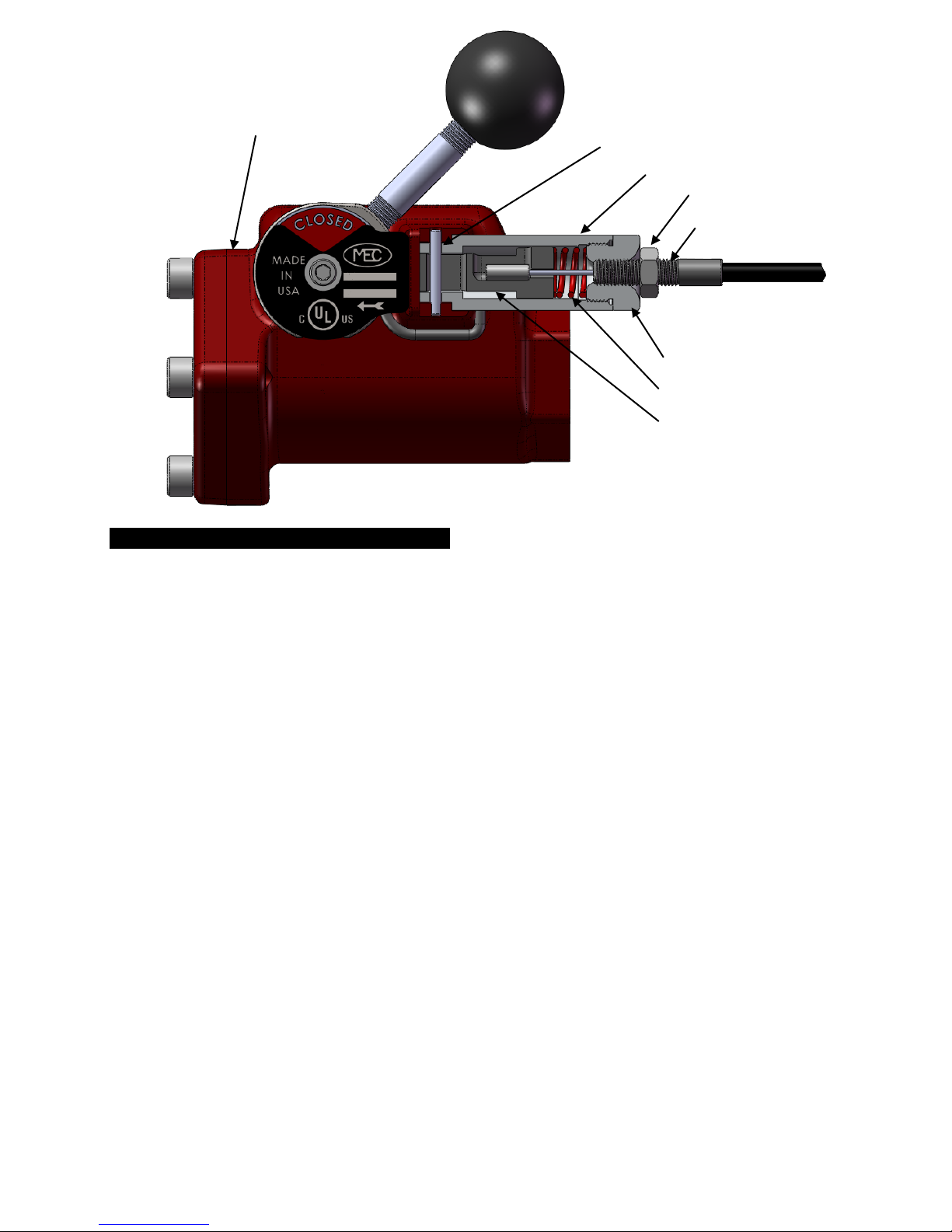

CABLE RELEASE CONNECTIONS

WARNING!

Remote release cables shall be installed so that

they will close the ME980 valve(s) when pulled

from the farthest remote location. Cable shall

operate smoothly, over pulleys and/or through

conduit. Do not kink cable or run cable around

sharp corners. If installed in conduit, keep water

out of conduit. Frozen water, dirt or dried mud in

the conduit will render the remote release

inoperable.

Remote releases used on ME980 valves shall not:

(a) be made from plastic or fiber rope;

(b) have any kind of fusible link which could melt

and prevent the cable from pulling the ME980

latch.

To provide a remote release, aircraft cable can be

connected to the short looped cable on the valve

and run to the remote release point over pulleys or

through conduit. Adjust the cable so that minimal

pull is required to close the emergency valves.

ME980-906-25 or ME980-906-50

Cable Installation

To connect an ME980 remote release assembly,

which is supplied with either 25' or 50' of cable:

1. Run the inner cable and housing assembly

to the remote release point. Leave enough

slack on each end for a smooth, flowing

path, without sharp bends in the cable,

between the ME980 latch and remote

release handle.

2. If it is necessary to cut the cable to a shorter

length, pull about one foot of inner cable

from the ME980 latch cable end (end with

the 3/16 by 1/2" long cylindrical cast fitting,

(see Figure 1) from the housing.

At the remote release end (other end of

inner cable housing assembly), cut the cable

jacket and inner cable at desired length.

Push the excess inner cable back through

the housing so that the bare cable extends

from the remote release end.

3. Close the ME980 valve

4. Unscrew the cable guide from the latch

body.

5. Remove the latch pin from the valve body

and remove the latch body from the valve

body.

6. Remove the plunger, spring and lanyard

(not shown).

7. Thread the cable guide onto the latch end

cable fitting and tighten the jam nut.

8. Install the spring on the cable and insert the

cable end in the plunger.