8 of 16

104 S. 8th Ave. Marshalltown, IA Phone 800-888-0127 / 641-753-0127 • Fax 800-477-6341 / 641-753-6341 www.

marshalltown

.com

WS570

R10-15-12

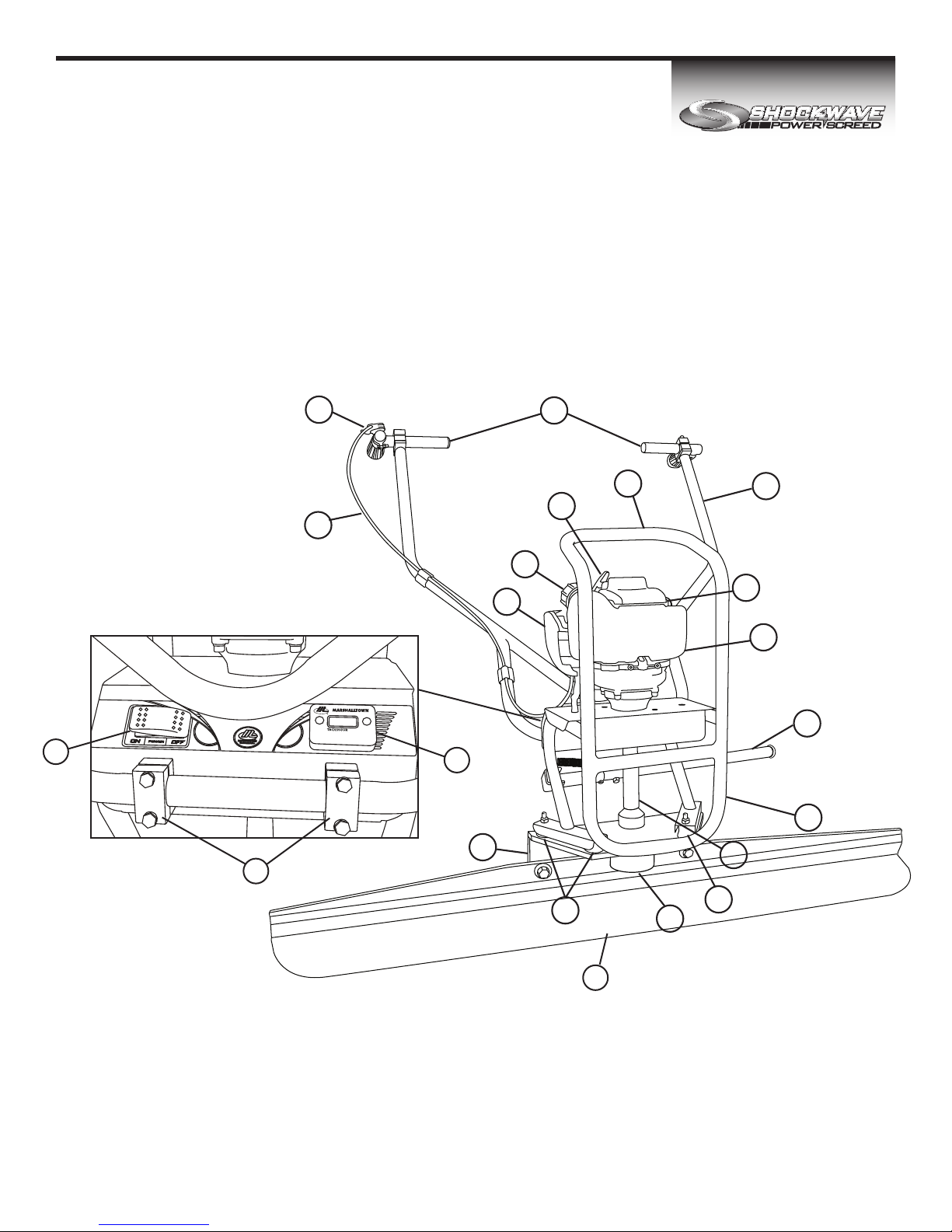

DETAIL A

A

16

46

44

20

45

3

1

17

5

22

24

4

33

19

39

7

8

29

9

11

30

35

32

27

31

12

34

28

47

47

2

23

43

26

48

17

18

2

2

15

21

10

13

14

33

25

37

38

41

36

42

40

49

6

DET. QTY. DESCRIPTION

1 1 GX35 HONDA MOTOR

2 8 HANDLEBAR CLAMP

3 1 HANDLEBAR ASSEMBLY

4 1 BASE EXTRUSION

5 1 TACHOMETER

6 1 KILL SWITCH

7 4 VIBRATION ISOLATOR

8 1 ECCENTRIC WEIGHT #1

9 1 ECCENTRIC WEIGHT #2

10 1 ECCENTRIC SHAFT

11 1 ECCENTRIC WEIGHT BUSHING

12 1 WEIGHT ADJUSTMENT CAP

13 1 LOWER BEARING HOUSING

14 1 COUPLING DRIVE SHAFT

15 1 CLUTCH

16 1 FLEX SHAFT

17 1 HANDLEBARS, L-GRIP

18 1 HANDLEBARS, T-GRIP

19 2 BLADE ATTACHMENT NUT

20 1 BLADE

21 1 KICKSTAND END

22 1 KICKSTAND ARM

23 2 KICKSTAND EYEBOLT

24 1 KICKSTAND END CAP

25 1 SPRING

26 1 FRAME

27 1 ECCENTRIC COVER

28 1 ECCENTRIC COVER CAP

29 3 DRIVETRAIN BASE MOUNTING SCREW

30 1 ECCENTRIC WEIGHT JAM NUT

31 1 ECCENTRIC TIGHTENING CAP BOLT

32 2 BLADE ATTACHMENT BOLT

33 4 ECCENTRIC COVER MOUNTING SCREW

34 4 ECCENTRIC CAP SCREW

35 8 VIBRATION ISOLATOR NUT

36 4 WELD NUT FOR HANDLEBAR CLAMPS

37 2 TACHOMETER MOUNTING SCREW

38 2 TACHOMETER MOUNTING NUT

39 4 VIBRATION ISOLATOR NUT

40 2 BLADE ATTACHMENT LOCK WASHER

41 8 HANDLEBAR CLAMP BOLT

42 2 KICKSTAND NUT

43 2 KICKSTAND BOLT

44 1 REPLACEMENT DRIVESHAFT CORE (NOT PICTURED)

45 1 THROTTLE LEVER ( FRICTION STYLE)

46 4 ENGINE MOUNTING BOLTS

47 2 HANDLEBAR GRIPS

48 1 THROTTLE CABLE

49 1 KILL SWITCH WIRING

REPLACEMENT PARTS INDEX

EDI PART# DESCRIPTION DETAILS INCLUDED

13308 13308 HANDLES WITH GRIPS 17, 18, 47

13309 13309 GRIPS 47

13310 ENG-HONDA HONDA ENGINE 1, 46

13312 13312 THROTTLE LEVER 45

13313 13313 THROTTLE CABLE 48

13314 13314 HANDLEBARS 3

13315 13315 HANDLEBAR CLAMPS W/HARDWARE 2, 41

13316 13316 HANDLEBAR CLAMP HARDWARE ONLY 41

13317 13317 ON/OFF SWITCH W/WIRES 6, 49

13318 13318 ON/OFF SWITCH WIRES 49

13319 13319 TACHOMETER 5, 37, 38

13320 13320 ECCENTRIC COVER W/HARDWARE 27, 28, 33, 34

13321 13321 KICKSTAND 21, 22, 23, 24, 25, 42, 43

13322 13322 KICKSTAND HARDWARE 23, 25, 42, 43

13323 13323 DRIVE TRAIN 10, 13, 14, 16, 29, 44

13324 13324 CLUTCH 15, 46

13325 13325 VIBRATION DAMPENING KIT 7, 35, 39

13330 13330 ECCENTRIC WEIGHTS & HARDWARE 8, 9, 11, 12, 30, 31

13331 13331 ECCENTRIC WEIGHT HARDWARE ONLY 11, 12, 30, 31

13332 13332 MACHINE BASE 4

13333 13333 BLADE LOCKING HARDWARE 19, 32, 40

13334 13334 DRIVE SHAFT 44

13335 13335 DRIVE SHAFT HOUSING 10, 13, 14, 16

12951 12951 FRAME ONLY 26

12952 12952 ECCENTRIC COVER HARDWARE ONLY 33, 34

PARTS BREAKDOWN