2 of 14 WS1716

3-2017/Rev.A

TABLE OF CONTENTS

Safety Precaution ............................................... 2

Common Components ........................................... 3

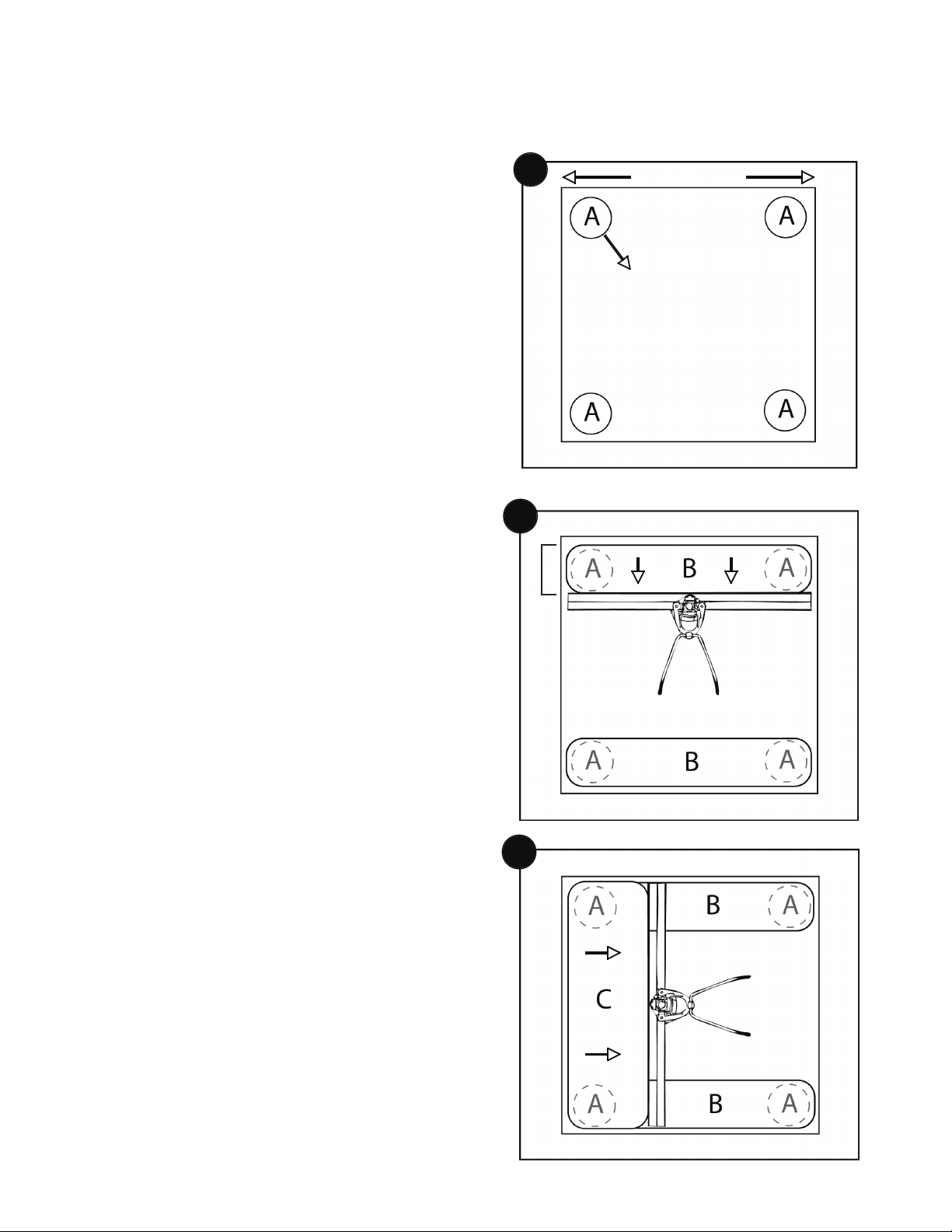

Assembly Instructions ..........................................4-6

Machine Adjustments ............................................ 7

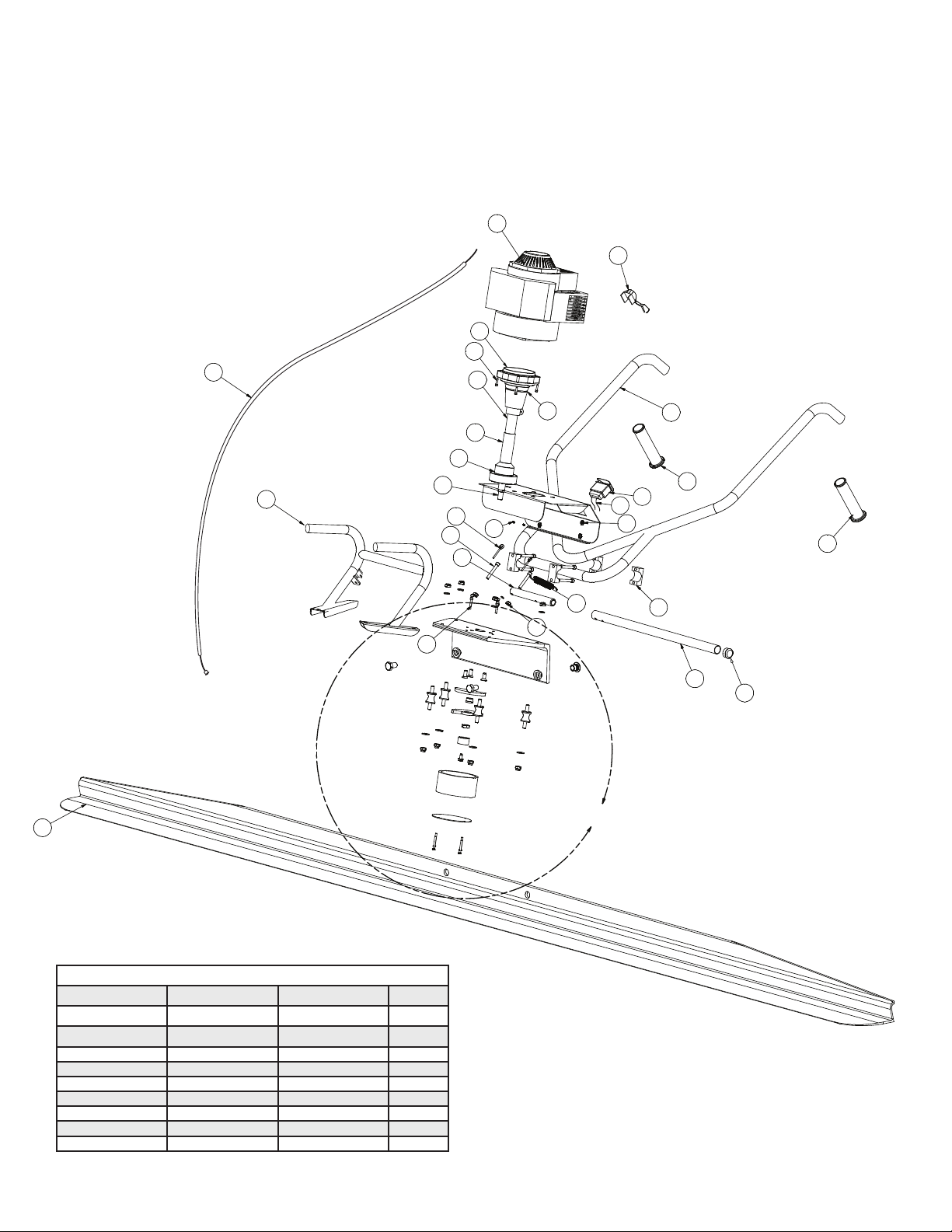

Parts Breakdown ..............................................8-9

Wet Screeding ................................................ 10

Form to Form Screeding ........................................ 11

Technical Data/Capacities ....................................... 12

Maintenance Schedule.......................................... 12

How to Operate .............................................13-14

This machine was built with user safety in mind, however, it can present hazards if improperly operated and serviced. Follow

operating instructions carefully and use good judgement when operating!

CALIFORNIA PROPOSITION 65 WARNING: Operation of this equipment and/or engine exhaust from this product

contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

SAFETY PRECAUTION

ALWAYS

• Always stop engine between loads of concrete

• Always screed while walking backwards

• Always clearly mark and be aware of all grade pins,

form stakes or other trip hazards

• Always follow all safety warnings and labels of the

engine manufacturer

• Always read and understand the owners manual of

the engine manufacturer

•

Always wear approved hearing, eye and breathing protection

• Always use form oil to coat blade or other parts susceptible

to concrete build up (avoiding electrical connections) before

each use

• Always properly secure screed before transporting

• Always follow recommended maintenance schedules

• Always make sure all connections and fasteners are tight

before every use

• Always make sure engine is in "OFF" position when

servicing or not in use

• Always use in a well ventilated area

• Always keep Speed Striker™ and engine manual handy

on the job site

• Always replace parts as they become damaged or worn

NEVER

•

Never operate screed without all parts and safety

covers correctly attached

•

Never allow children to operate

• Never operate under the influence of drugs or alcohol

• Never use screed for anything other than its

intended purpose

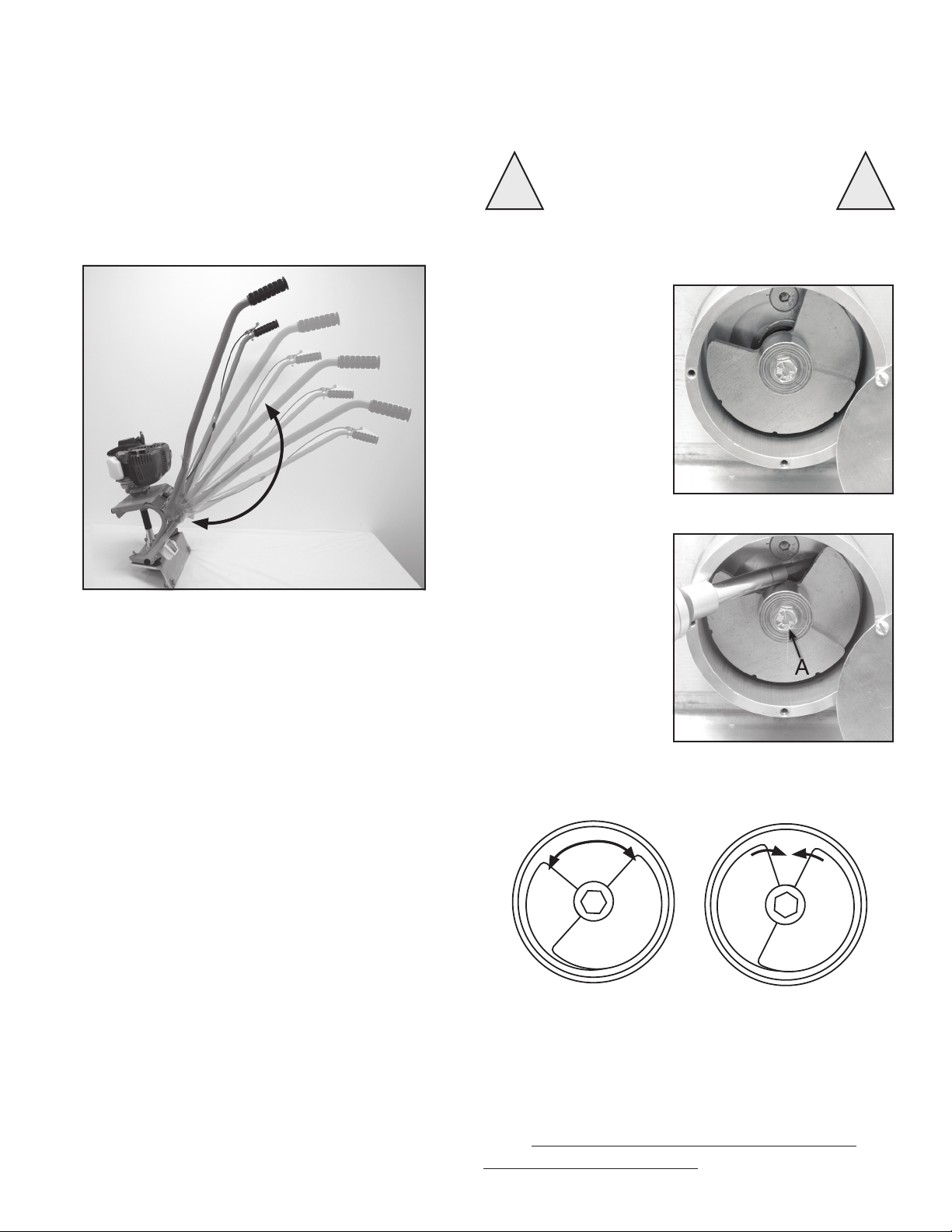

• Never set eccentric weights to where excessive vibration

occurs at low RPM (weights too far open)

• Never set eccentric weights to where it takes excessive

RPM to make weights vibrate (weights too far closed)

• Never allow engine to run unattended or idle on

top of wet concrete

• Never place concrete higher than the leading

“curl edge” of the blade

•

Never fill gas tank while engine is running

•

Never start engine near spilt fuel

•

Never fill gas tank, operate, or service screed

near open flame

• Never use parts or blades from other manufacturers

• Never service a hot engine

• Never operate without proper training

• Never spray water or other liquid on a hot engine