10 of 68

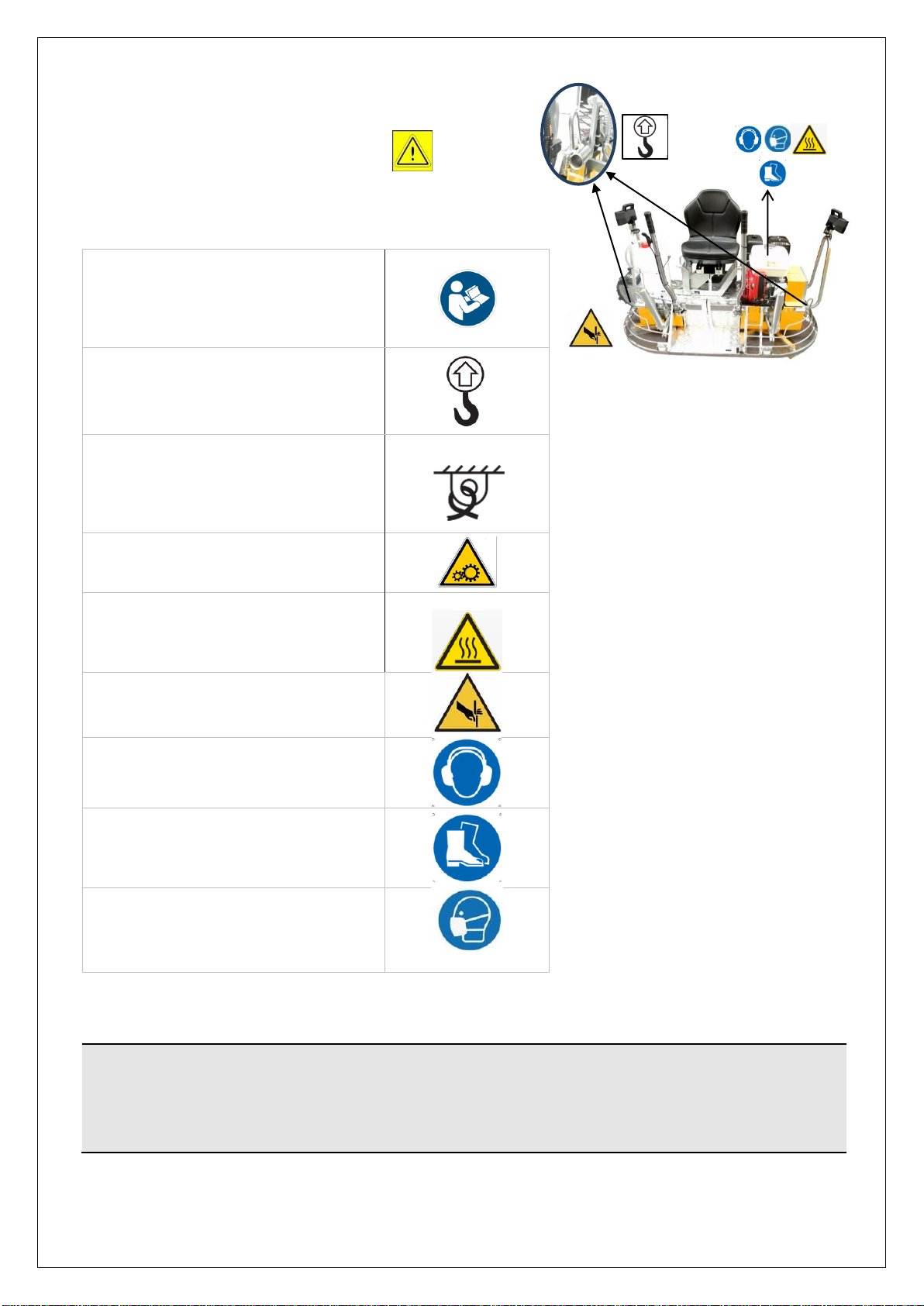

1.3. SYMBOLS AND GLOSSARY

●HAZARD: A potential source

of injury or damage to health;

●HAZARDOUS AREA: Any area within

and/or in the vicinity of the machine

where the presence of a person

constitutes a risk to the health and

safety of the said person;

●EXPOSED PERSON: Any person

wholly or partially located in a

hazardous area;

●OPERATOR: The person or persons

tasked with installing, operating,

adjusting, cleaning, repairing and

moving a machine or performing its

maintenance;

●RISK: Combination of likelihood and

severity of an injury or harm to health

that can arise in a dangerous

situation;

●INTENDED USE: the use of the

machine in accordance with the

information provided in the

Instructions for Use (Par. 2.2);

●ANY REASONABLY

FORESEEABLE MISUSE: Machine

use other than that indicated in the

instructions for use, but that may

derive from the easily predictable

human behaviour;

●HUMAN-MACHINE INTERACTION:

Any situation in which an operator has

to interact with the machine in any of

the operational phases at any

moment in the machine’s life;

●OPERATOR QUALIFICATION:

Minimum level of skills that the

operator must possess in order to

carry out the described operation;

●NUMBER OF OPERATORS:

Appropriate number of operators to

optimally carry out the operation

described and deriving from a careful

analysis conducted by the

"Manufacturer", meanwhile the use of

a different number of

workers could prevent the desi

red

result from being achieved or endanger

the safety of the personnel involved;

●MACHINE STATUS means:

The mode of operation: automatic

gear, manual operation, shutdown.

The condition of the safety devices on

the machine: with or without guards,

emergency shut-down pressed, type

of selection of energy sources, etc.;

●GUARD: Piece of the machine used

specifically for protection through a

material barrier;

●SAFE SHUT-DOWN: Condition of

shut-down obtained with safety

measures which avoid unexpected

start-ups of hazardous parts;

●RESIDUAL RISK: Risk that has not

been possible to eliminate or

sufficiently reduce through the design,

against which the protections are not

(or are not totally) effective;

●The manual gives information of its

existence and instructions/warnings to

avoid it;

●SAFETY COMPONENT: Means a

component used for ensuring a safety

function and whose breakdown or

malfunction affects the safety and/or

health of exposed persons (eg. lifting

device; fixed, mobile, adjustable

guard, etc., electrical, electronic,

optical, pneumatic, hydraulic device,

guard interlocking, etc.).

●ABBREVIATIONS:

●CHAP. = Chapter

●PAR. = Paragraph

●PAG. = Page

●FIG. = Figure

●TAB. = Table

●P.P.E. = Personal protective equipment

●CFR = see