Potentiometer/PWM

Relationship

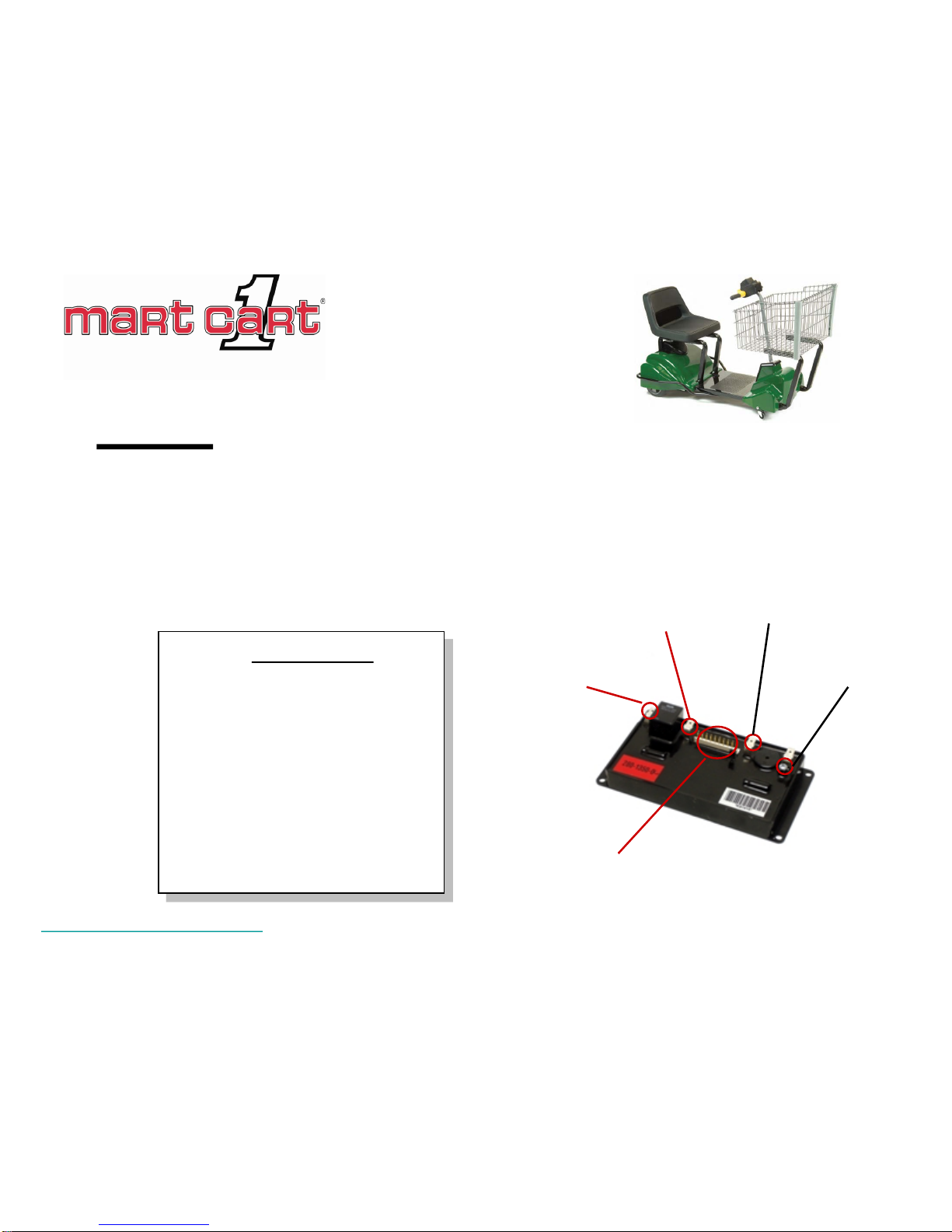

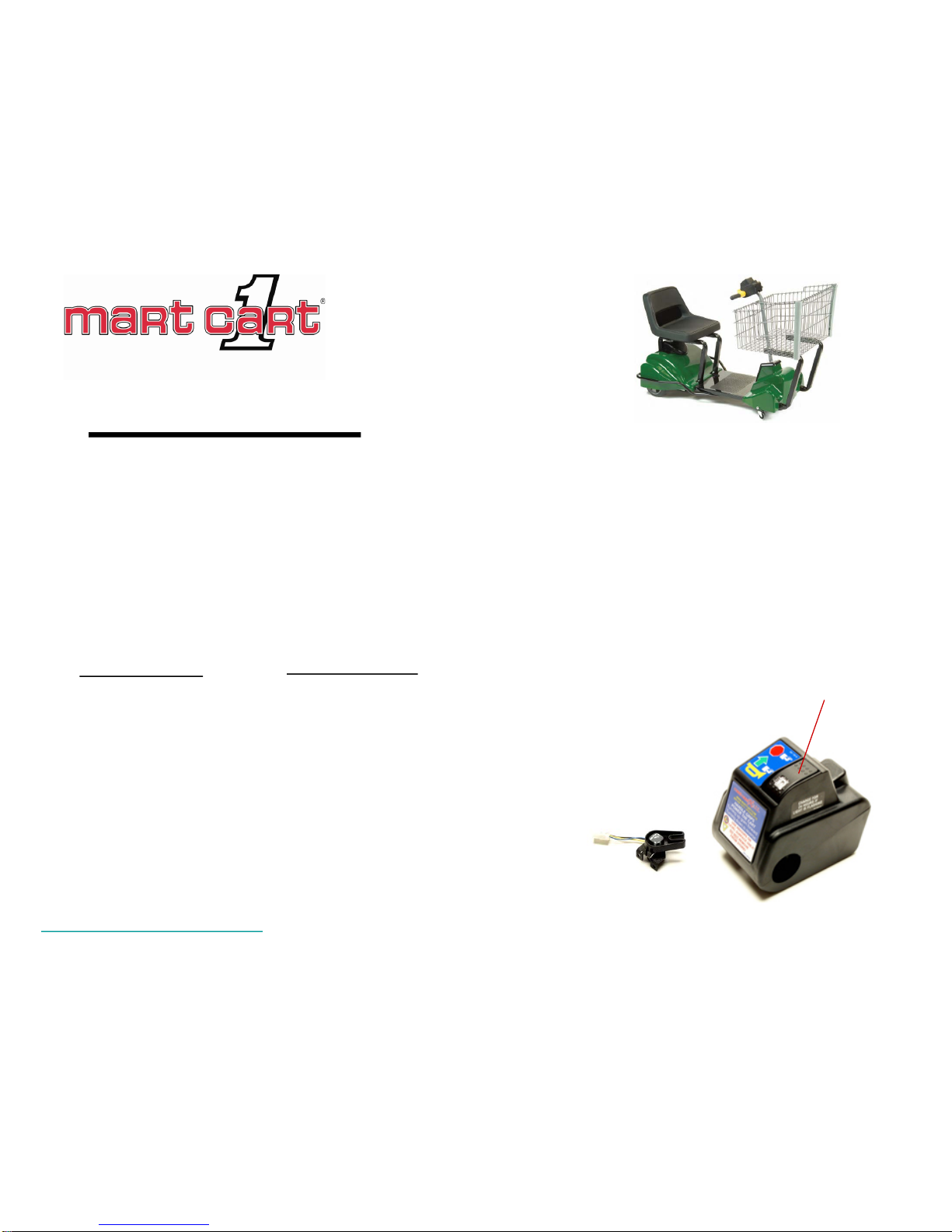

The potentiometer (pot) along with the PWM regulates the speed and direction of the motor. The

PWM monitors the change in resistance on pins 1, 2, and 3 of the 10-pin connector which are

connected to the pot (pins 1, 2, and 3 respectively) through the steering wire harness. The pot is

located in the control box and is physically connected to the throttle control on the cart’s

handlebars. The resistance is varied by the movement of the thumb-control throttle in a forward

and backward direction.

In turn, the PWM emits variable voltage to the positive and negative motor leads (connected to the

PWM), allowing the motor to move at varied speeds forward and backward.

The pot is rated at 5K ohms +/- 10%. This is the resistance between pin 1 and pin 3 on the pot’s

terminals. When the pot assembly is set at the factory, the wiper (pin 2) is calculated and preset to

24% of the total resistance (approx 1.08K to 1.32K ohms). The wiper position of the pot is where

the PWM looks for the “neutral” position. In the neutral position, the PWM cuts power to the motor

leads and brake leads (engaging the brake).

Continued on next page 1

2 3

Pot PWM Hub Motor