1

General Information and Warnings......................................................................................................2

Denition of Symbols.....................................................................................................................2

Product Disposal ...........................................................................................................................2

Interference with Electromedical Devices......................................................................................2

Incompatible Devices and/or Accessories .....................................................................................2

Obtaining Technical Literature .......................................................................................................2

Safety Notes........................................................................................................................................3

Storage Conditions ........................................................................................................................3

Technical Specications for the Dental Light.......................................................................................4

Technical Description — Light .......................................................................................................4

Electrical Specications.................................................................................................................4

Light Specications........................................................................................................................4

Replacement Parts for Dental Lights.............................................................................................4

Safety Markings.............................................................................................................................4

Device Classication .....................................................................................................................4

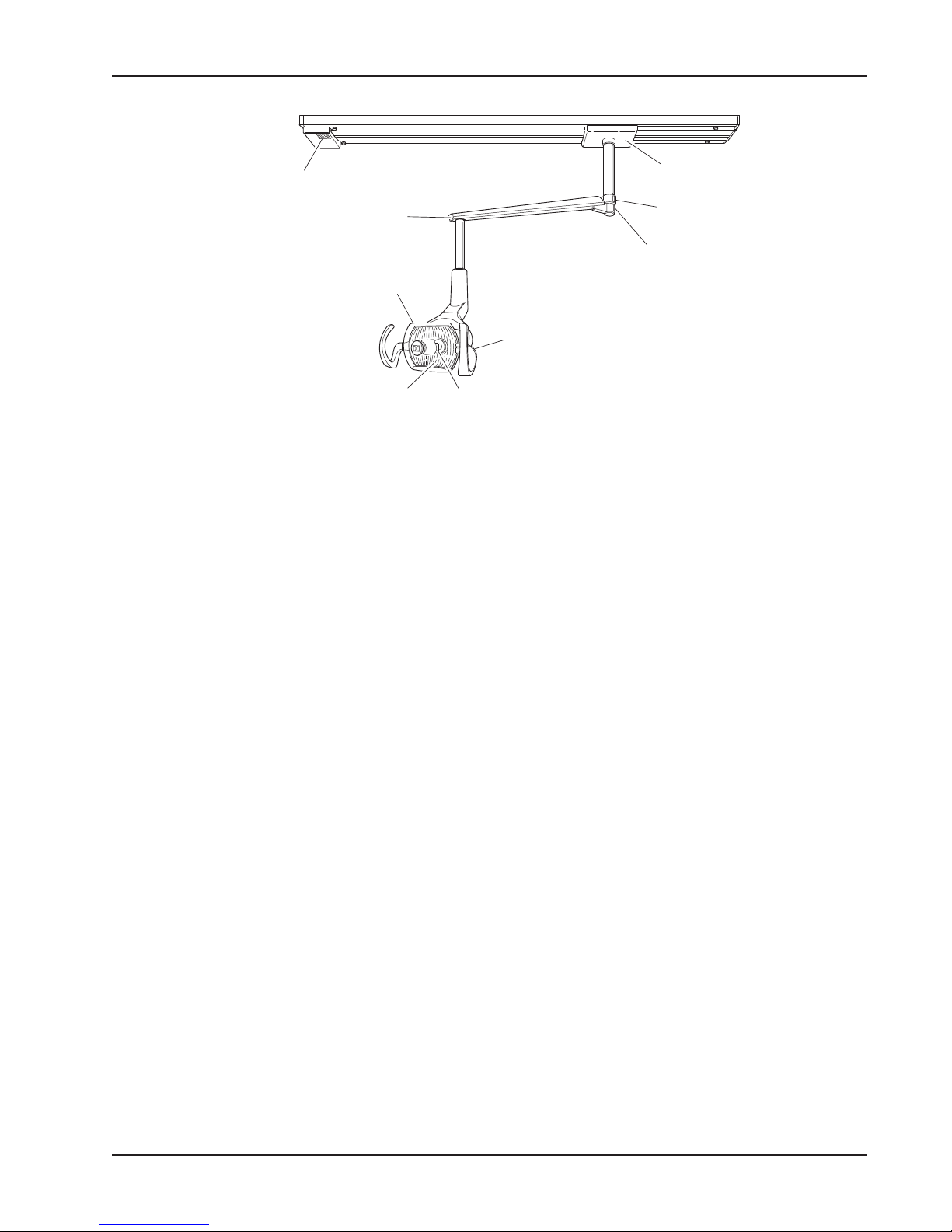

Overview / Replacement Parts............................................................................................................5

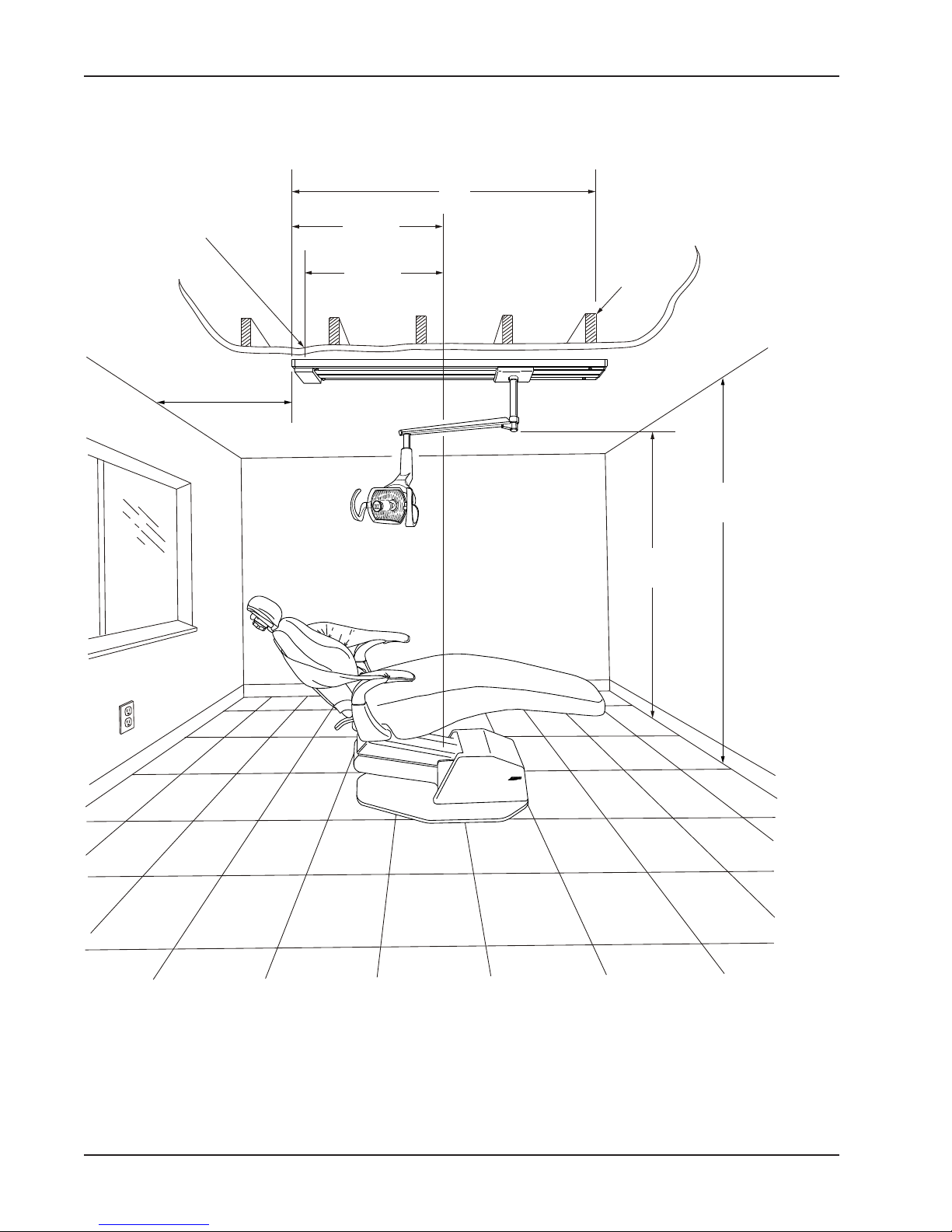

Suggested Mounting Methods.............................................................................................................6

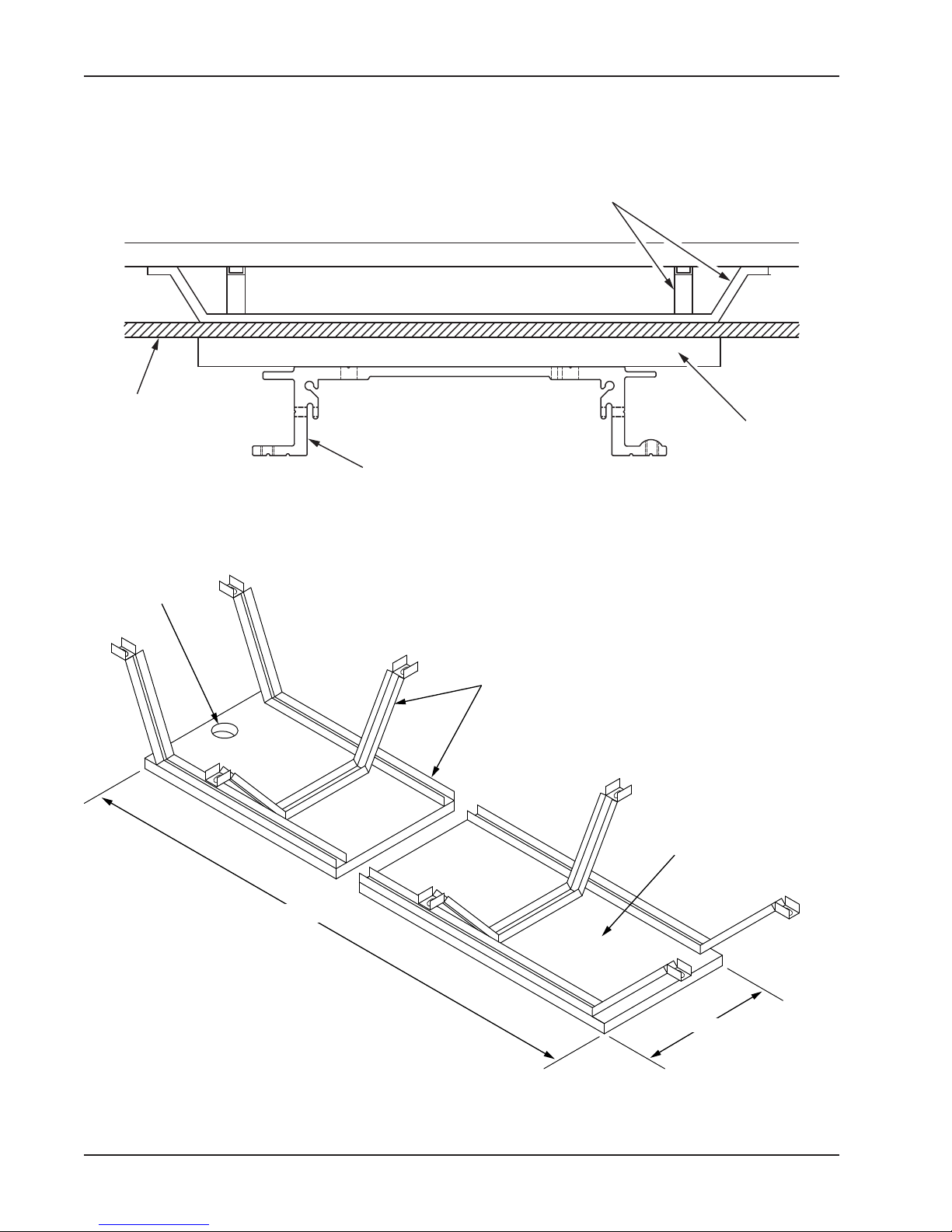

Suggestions for Suspended Ceiling ....................................................................................................7

Mounting Parallel and Perpendicular.............................................................................................9

Electrical Requirements.....................................................................................................................10

Installation Instructions......................................................................................................................10

Adjusting the Light-head’s Horizontal Rotation..................................................................................13

Adjusting the Light-head’s Vertical Rotation ......................................................................................13

Adjusting the Light-head’s Third Axis Rotation .................................................................................14

Focusing the Light .............................................................................................................................14

Turning the Light On and Off .............................................................................................................14

Replacing the Bulb ............................................................................................................................15

Adjusting the Auto-Switch(Optional)..................................................................................................16

Flex Arm Adjustment..........................................................................................................................16

Vertical.........................................................................................................................................16

Horizontal ....................................................................................................................................16

Cleaning the Light..............................................................................................................................17

WARNINGS, DISINFECTING & STERILIZATION - LIGHTS ......................................................17

Unacceptable Disinfectants.........................................................................................................17

Conditionally Acceptable Disinfectants* ......................................................................................17

Cleaning Reector and Cover .....................................................................................................18

Dimensions and Range of Motion - TL 500 Track Light.....................................................................19

Dimensions and Range of Motion - Light Head.................................................................................21

Service Location - Track Light Power Supply....................................................................................21

Service Location - Light Head ...........................................................................................................22

Electrical Schematics ........................................................................................................................23

Electromagnetic Compatibility ...........................................................................................................25

Checklist............................................................................................................................................29

Table of Contents