6

It is usually co ve ie t to carry the same material right up to the ceili g level. At the lower

edge, drill (4.5mm diameter) holes i to the metal support a gle through the holes i the top

fla ge of the shieldi g box a d faste with the self threadi g screws provided. The side clad-

ding of the e closure may be Gib board or a y other wall claddi g material. You must leave

the claddi g off at least o e side u til the flue system has bee i stalled.

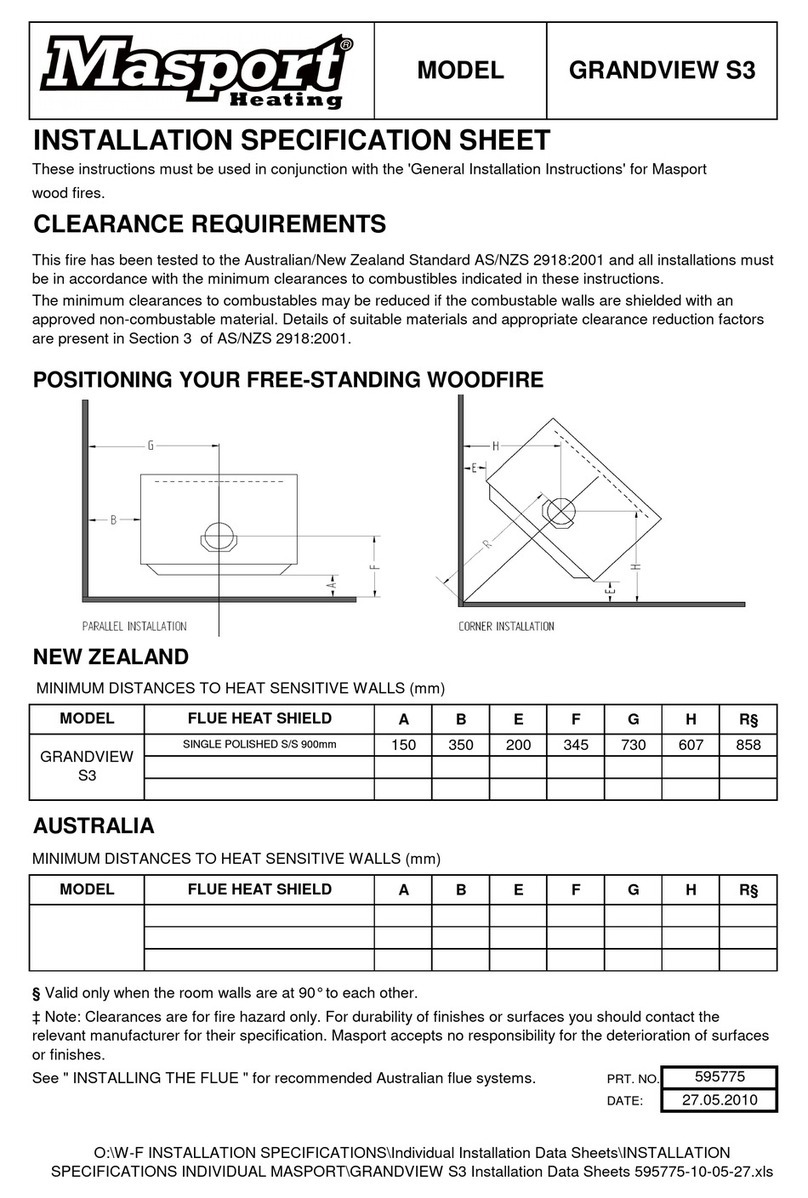

7. For heat se sitive floors, co struct a insulating floor protector of the shape show i the

Floor Pla above. (see below for co crete floors). The sta dard i sulati g floor protector is

co structed of two layers of 16mm thick MICORE 160 or o e layer of WOODTEX 35mm thick,

topped with a 6mm sheet of Hardies TILE & SLATE UNDERLAY a d a layer of tiles or slate.

This will give a thick ess of approximately 50mm, a d the exte sio from the face of the fro t

claddi g must be at least 525mm. The floor protector must be at least 1025mm wide. It is de-

sirable to carry the floor protector all the way i side the e closure to e sure that the bottom of

the shieldi g box does ot rest below the top surface of the floor protector.

8. Note: For elevated installations (bottom of the shieldi g box rails at least 300mm above floor

level), the floor protector may be i stalled after the heater is i positio as it does ot exte d

i to the e closure. However, its rear edge must butt up agai st the face of the heat-proof fro t

claddi g below the heater, a d the joi t at that poi t must be sealed to preve t the possibility

of ember pe etratio . I this case a ash floor protector is sufficie t. Co structio require-

me ts for a ash floor protector are: o e sheet of 6mm fibre ceme t board (e.g. Hardies TILE

& SLATE UNDERLAY) covered with ceramic tiles or slate.

9. Ceme t tiles or slate to the top of the floor protector. The part i side the e closure will ot be

visible a d therefore does ot eed complete coverage. It is ecessary to fix the fi ishi g layer

o ly u der the support rails i this area. The visible edges of the floor protector are best fi -

ished with woode trim or tiles after the stove has bee i stalled.

10. Pe etrate the roofi g material o the flue ce terli e. Worki g from the bottom, assemble sec-

tio s of the flue and the inner and outer flue casings a d pass them up through the hole i

the roof. Remember the flue sectio s must be fixed together at each joi t with at least two rust-

proof faste ers, a d the crimped e ds of the flue casi gs go to the top. Whe the flue system

is fi ally i positio , the top of the i er casi g a d the top of the outer casi gs must be at the

same height. If the flue ce terli e is withi 3m from the ridge, the outer casi g must e d at

least 600mm above the ridge. If it is further tha 3m from the ridge, the shield must exte d at

least 900mmabove the poi t of roof pe etratio . I some cases where there are trees or high

buildi gs i the vici ity, it may be ecessary to i crease the height to avoid dow -draughts.

Note that the special adapter spigot ri g with holes to ve tilate the space betwee the flue a d

the i er casi g as well as the space betwee the i er casi g a d the outer casi g has to be

attached with 4 screws a d locki g uts to the top of the shieldi g box. Both flue casi gs

(i er & outer) will e gage with this special adapter spigot ri g. The fitti g of the special adap-

tor spigot ri g to the top of the shieldi g box should be do e after the shieldi g box has bee

pushed i to the e closure.

11. Assem le the base, sides, back, top shield assembly a d top pa el of the shielding ox. The

top shield rests o the top edges of the i er heat shields of the cabi et. Make sure the back

fla ge hooks over the shield o the rear pa el (See Fig. 3).

12. Attach the two sta doff brackets to the sides of the shieldi g box pa els (if ot already fitted).

Use four pop rivets for each bracket.

13. Slide the assem ly into place in the enclosure. After ce tralizi g, fix the fla ge of the top

pa el of the shieldi g box through the claddi g i to the metal a gle support. Use 2/ 12g x

25mm screws. Attach the special adapter spigot ri g to the top pa el of the shieldi g box. Use

4 screws 8g x 13mm.

14. I New Zeala d a d some parts of Australia, Sta dards require that the woodfire be secured

to preve t shifti g i the eve t of a earthquake. To provide seismic restraint, fix the

shielding ox to the floor (bearers i a elevated i stallatio ) with two 6mm maso ry a -

chors (DYNABOLTS) or two 12 gauge screws . Use the two holes i the bottom of the shield-

i g box spaced 687mm apart.

15. Now go to the fire ox ca inet a d remove the two retai i g screws a d slide out the top sec-

tio of the firebox cabi et.

16. Attach the two ce tralizi g a gles to the side pa els of the firebox cabi et, fla ges faci g for-