6

8. Wall surfaces directly above the heater may reach 85 degrees C, so materials such as

wallpaper and water based paint may be adversely affected. For durability of finishes

and surfaces you should contact the relevant manufacturers for their specifications.

Glen Dimplex accepts no responsibility for the deterioration of surfaces of finishes. It is

usually convenient to carry the same material right up to the ceiling level. At the lower edge,

drill (4.5mm diameter) holes into the metal support angle through the holes in the top flange of

the shielding box and fasten with the self threading screws provided.

9. Mantel Pillars: You are allowed to have combustible mantel pillars. They mast be placed at

least 460mm from the centre of the appliance and must not protrude more than 100mm from

the wall where the fascia is butting against.

10. For heat sensitive floors, construct an insulating floor protector of the shape shown in the

Floor Plan (Fig.2) and projection sizes on page 11, (see below for concrete floors). The insu-

lating floor protector is constructed of one layer of 6mm thick PROMATECT H or SUPALUX,

topped with a layer of tiles or slate. The floor protector must be at least 875mm wide. It is de-

sirable to carry the floor protector all the way inside the enclosure to ensure that the bottom of

the shielding box does not rest below the top surface of the floor protector.

11. Note: For elevated installations (bottom of the shielding box rails at least 300mm above floor

level), the floor protector (min. size: 300mm from cladding x 875mm wide) may be installed

after the appliance is in position as it does not extend into the enclosure. However, its rear

edge must butt up against the face of the heat-proof front cladding below the appliance, and

the joint at that point must be sealed to prevent the possibility of ember penetration. In this

case an ash floor protector is sufficient. Construction requirements for an ash floor protector

are: one sheet of 6mm fibre cement board (e.g. Hardies TILE & SLATE UNDERLAY) covered

with ceramic tiles or slate.

12. Cement tiles or slate to the top of the floor protector. The part inside the enclosure will not be

visible and therefore does not need complete coverage. It is necessary to fix the finishing layer

only under the support rails in this area. The visible edges of the floor protector are best fin-

ished with wooden trim or tiles after the stove has been installed.

13. Penetrate the roofing material on the flue centerline. Working from the bottom, assemble sec-

tions of the flue pipe and the inner and outer casings and pass them up through the hole in

the roof. Remember the flue pipe sections must be fixed together at each joint with at least

three monel or stainless steel fasteners, and the crimped ends of the flue casings go to the

top. The joints of the flue pipes must be sealed with an appropriate fire proof sealant. When

the flue system is in its final position, the top of the outer casings must be above the ridge line

or roof as follows: If the flue centerline is within 3m from the ridge, the outer casing must end

at least 600mm above the ridge. If it is further than 3m from the ridge, the outer casing must

extend at least 1000mm above the point of roof penetration. In some cases where there are

trees or high buildings in the vicinity, it may be necessary to increase the height to avoid down-

draughts. You need to temporary support the flue system so that you can install the appliance.

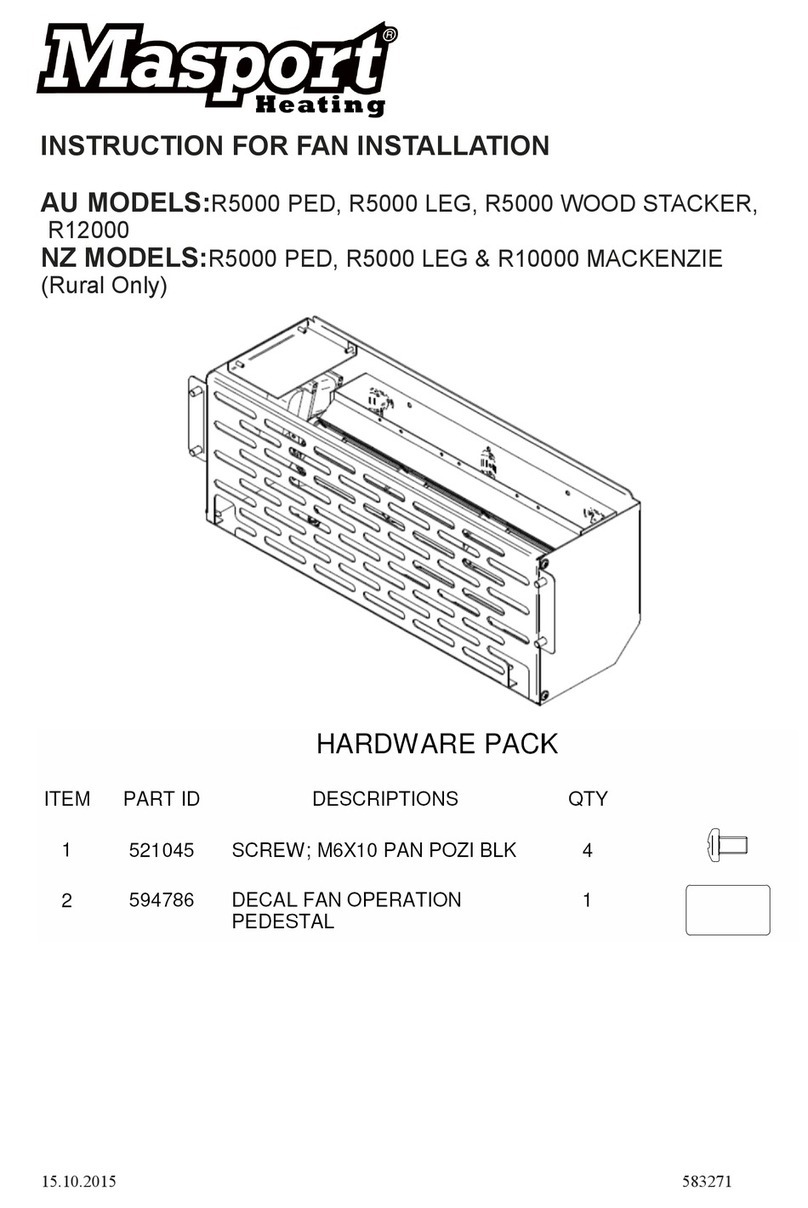

14. Assemble the base, sides, back, top shield assembly and top panel of the shielding box. The

top shield rests on the top edges of the inner heat shields of the cabinet. Make sure the back

flange hooks over the shield on the rear panel (See Fig. 3 and 3A).

15. Attach the two standoff brackets to the sides of the shielding box panels (if not already fitted).

Use four pop rivets for each bracket.

16. Slide the assembly into place in the enclosure. After centralizing, fix the flange of the top

panel of the shielding box through the cladding into the metal angle support. Use 2/ 12g x

25mm screws.

17. The special adapter spigot ring with holes to ventilate the space between the flue and the

inner casing as well as the space between the inner casing and the outer casing has to be at-

tached with 4 screws 8g x 13mm to the top of the shielding box. Both flue casings (inner &

outer) will engage with this special adapter spigot ring.

18. In New Zealand and some parts of Australia, Standards require that the appliance be seismic

restraint to prevent shifting in the event of an earthquake. To provide seismic restraint, fix

the shielding box to the floor (bearers in an elevated installation) with two 6mm masonry

anchors (DYNABOLTS) or two 12 gauge screws . Use the two holes in the bottom of the

shielding box spaced 687mm apart.