9

Cleaning

Caution! Parts of the extruder get hot! Wear gloves and eye protection!

It is recommended to thoroughly clean the extruder after use, or right

before the next use, for the most consistent extrusion. Polymer melt on

the screw due to heat creep after shutdown can cause issues when

restarting the extruder. Leave the extruder temperature zones on during

cleaning.

1. Either run the extruder until the feed port is empty or use a vacuum

cleaner to remove the remaining pellets. Continue running the

extruder until polymer stops extruding from the nozzle.

2. If you are using a filter nozzle, stop the extruder, remove it, and

replace it with a standard nozzle with a minimum hole size of 1.5mm.

Purge damages the filter. Fill the steel angled feed tube

approximately halfway with extruder purge compound while running

the extruder at approximately 20RPM. Do not change the

temperatures from the polymer that was run to run purge. NOTE:

Use high temp purge for temps over 300°C. It is possible to remove

and clean the screw without using purge material, but the process

can be significantly more difficult and is not recommended.

3. Continue running the extruder until

purge stops extruding from the

nozzle, or add more if the residual

polymer is still visible in the purge.

NOTE: Running the extruder “dry”

with no polymer in the feed will

cause excess wear on the screw

over time. Avoid running the

extruder while empty for more

than a few minutes at a time.

4. After all the purge has been

extruded, stop the extruder and

remove the nozzle.

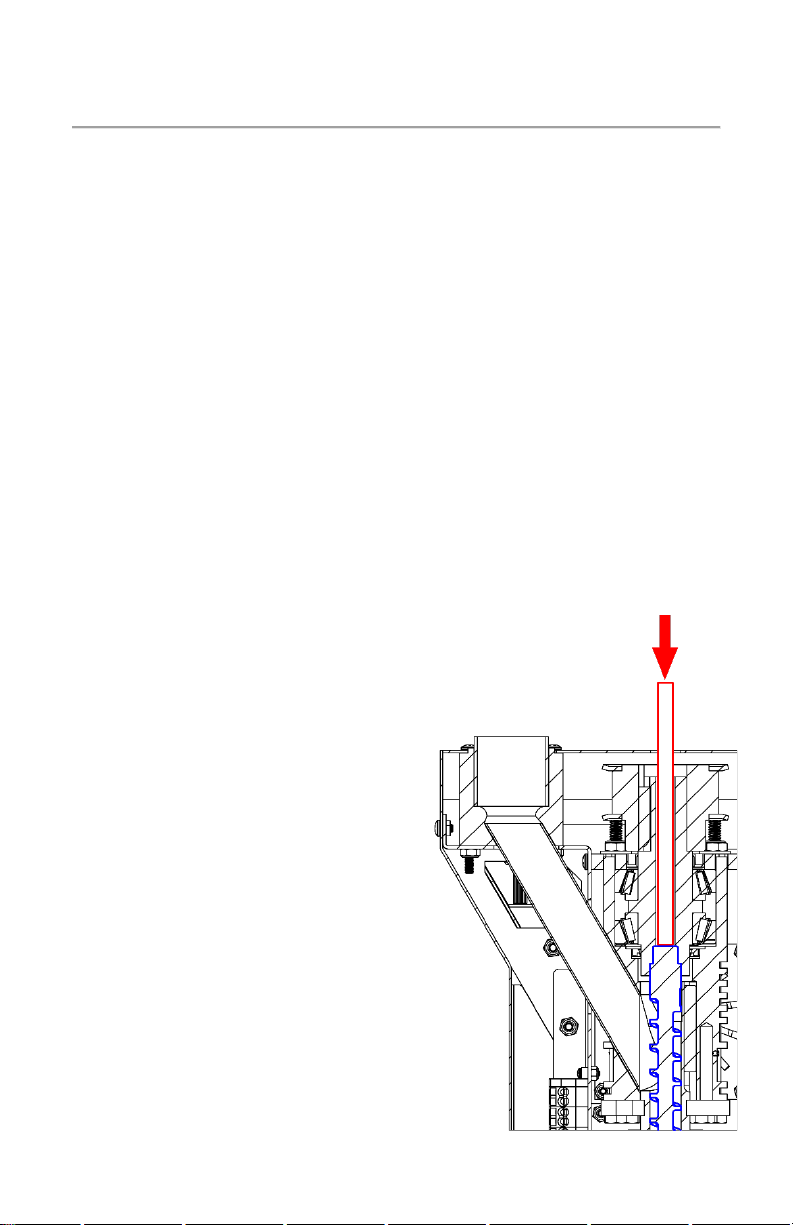

5. Remove the magnetic screw

retainer rod and insert the tube

cleaner extension rod to push the

screw forward and out from the

end of the barrel.