Dear Customer,

Thanks for choosing Master machine.

To ensure the safety and proper use of the machine, please read the

instruction book carefully before use.

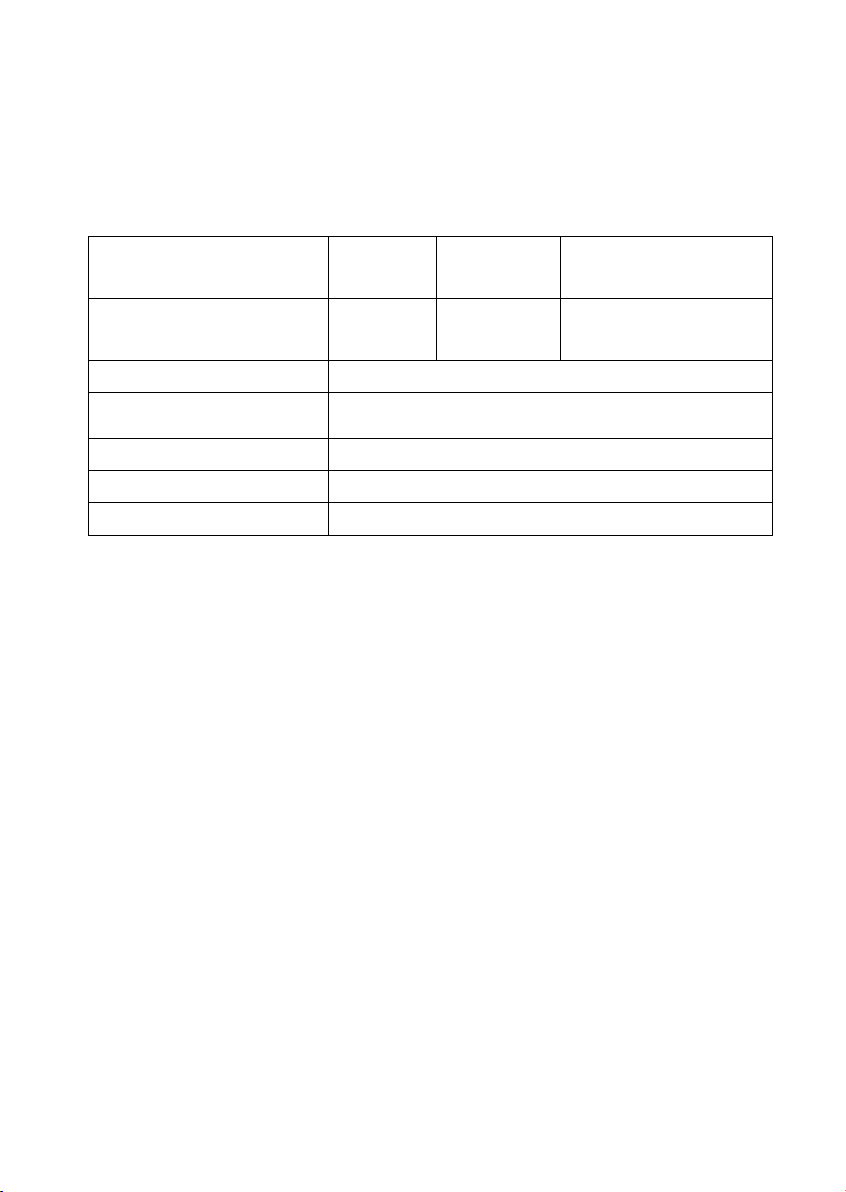

Also, please fill this card and save it for warranty use.

Thank you very much that you have purchased the products.

This operation manual will tell you how to correctly operate and maintain

your machine. Before using the machine, please read the operation manual

thoroughly to guarantee the correct operation. Following the operation

requirements in the operation manual will make that your machine is in the

best operation state so as to extend the life of the set. For you own safety and

protection injury, carefully read, understand and observe the safety

instructions described in this manual.

Keep this manual or a copy of it with the machine. This machine is built with

user safety in mind; however, it can present hazards if improperly operate and

serviced. Follow operating instructions carefully!