Page 10

10.1.1. Saving the radio remote control

The radio remote control supplied is the WI-CONTROL model, with 30 channels and a

display, which transmits at the radio frequency of 433.92 MHz; no other radio remote

control model is provided for the

CLOUD

RADIO. Several actuators can be controlled with

a single radio remote control, however each channel must correspond to a CLOUD RADIO

actuator and thus a window.

The encoding used varies for each channel, so each transmission will send a signal that is

different from all the others. It follows that the receiver must be able to recognize the

enabled transmitters, thus the transmission codes should be saved following the procedure

below:

Equip yourself with the radio remote control, checking beforehand that it is working,

has charged batteries and is in good condition.

Select the desired channel on the radio remote control. (Consult the instructions

manual of the WI-CONTROL radio remote control).

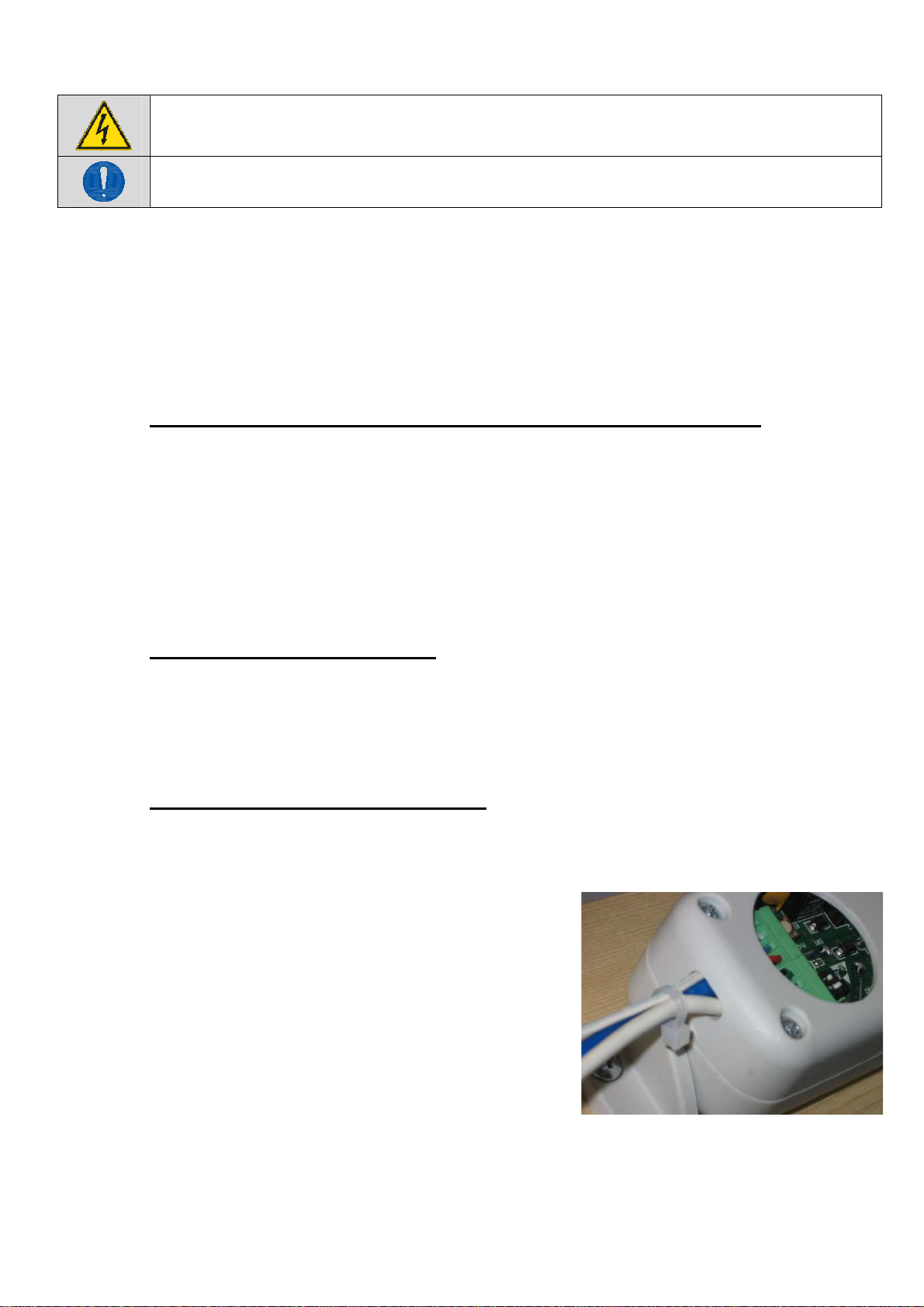

On the CLOUD RADIO, briefly press (for about 1 second) the small “

PRG

”button

located near the terminal block. The slowly flashing LED indicates that it is waiting to

receive a valid radio code.

Within 10 seconds, press any one of the up arrow ▲,

STOP

or down arrow ▼buttons

two times (once to activate the display of the radio remote control and the second

time to transmit the radio code).

If the code is saved correctly, the LED will emit one long flash (1 sec.) to confirm;

then the LED will go out and remain at rest.

If the code is not saved correctly - due to the memory being full, for example, or the

radio remote control being incompatible - the LED will emit a series of quick flashes

for about 1 second; then the LED will go out and remain at rest.

10.1.2. Erasing the radio memory

To completely erase the memory of the radio remote control on the machine, press the

“

PRG

”button and hold it pressed for about 20 seconds until the LED begins to flash quickly.

At this point you can release the button; the flashing continues until the memory has been

completely erased.

10.1.3. Remotely saving a radio remote control

A new radio remote control can be saved remotely – i.e., without accessing the

PRG

button

– only if at least one radio remote control has already been saved as described in point

10.1.1 and you have the radio remote control which is already recognized. To remotely

save a radio remote control, follow the procedure below:

Equip yourself with the WI-CONTROL radio remote control to be saved and set it on

the desired channel (see the instructions provided with the radio remote control).

Equip yourself with the radio remote control already saved and operating on the

CLOUD RADIO in question.

On the already saved radio remote control, press the following buttons in sequence:

F1, F2 and then

STOP

. This sequence “opens” the memory of the CLOUD RADIO (in

the same way as pressing the PRG button).