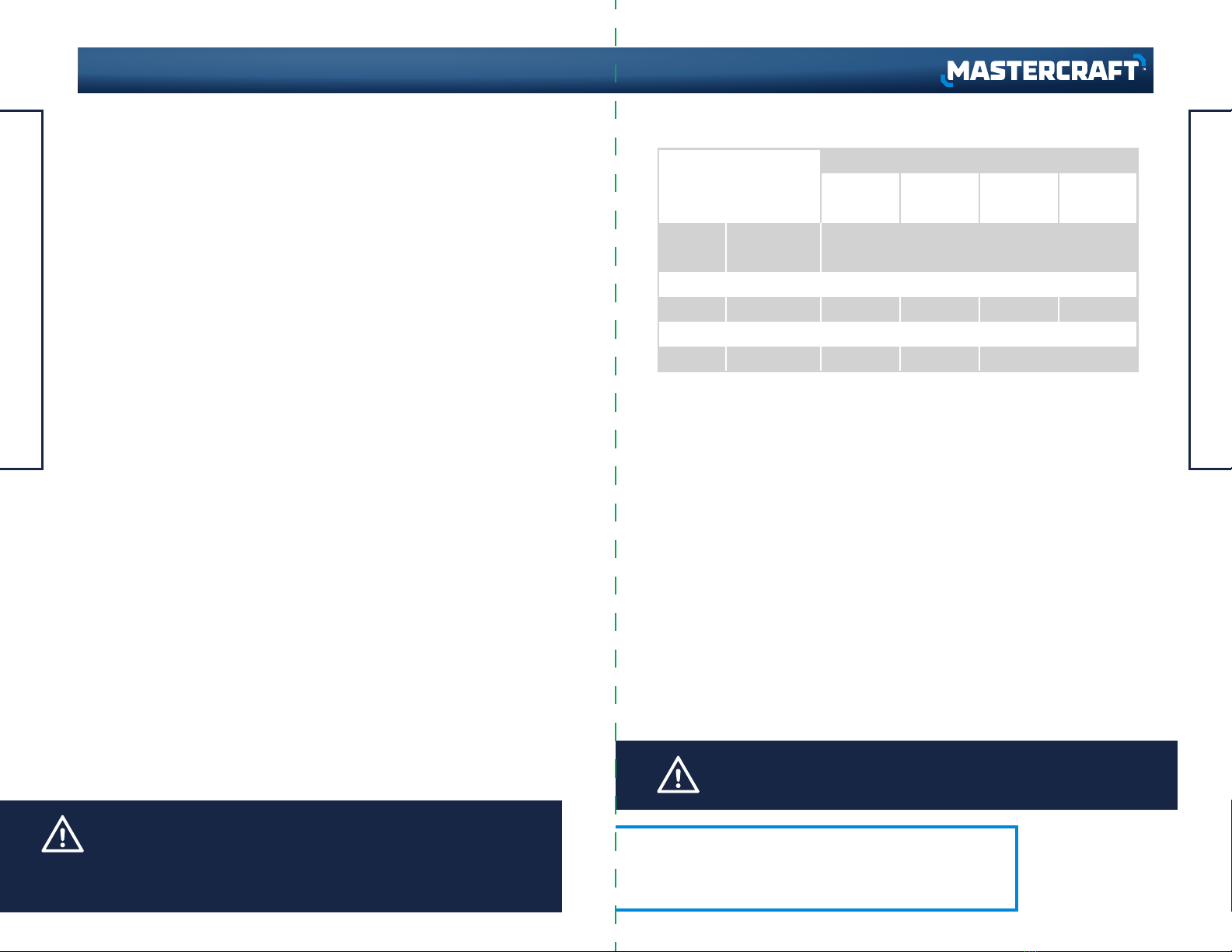

Three-prong plug

Grounding prong

Properly grounded outlet

Fig. 1

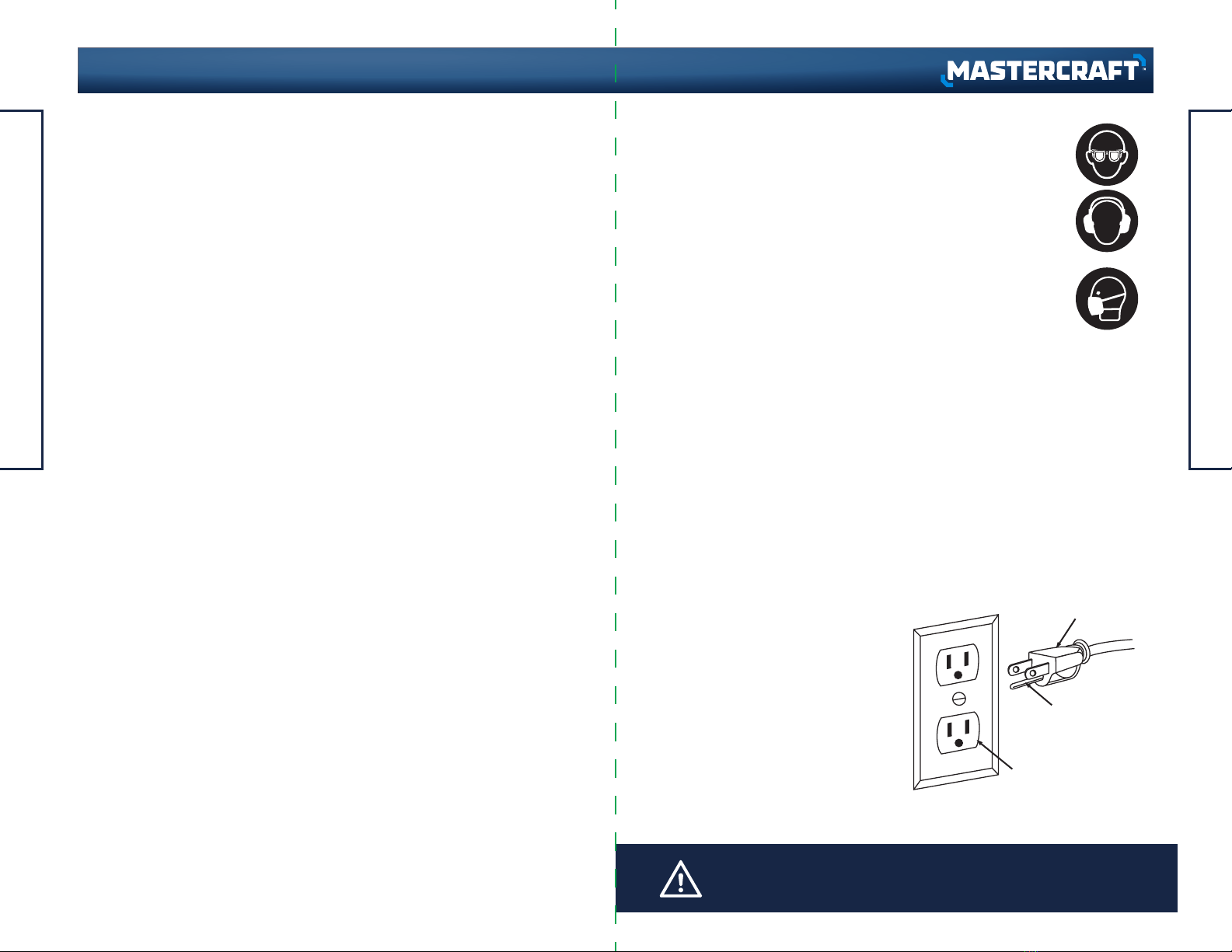

USE SAFETY GOGGLES AND EAR PROTECTION:

ALWAYS WEAR EYE PROTECTION THAT CONFORMS WITH CUL

REQUIREMENTS. FLYING DEBRIS can cause permanent eye damage.

The tool is loud and the sound can cause hearing damage. Always

wear ear protection to help prevent hearing damage and loss. Failure

to comply may result in moderate injury.

USE DUST MASK:

Some dust created by sawing contains chemicals that are known to

cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals come from lead-based paints; crystalline silica from

bricks, cement and other masonry products; and arsenic and chromium from

chemically treated lumber. To reduce exposure to these chemicals, work in a

well-ventilated area with approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

ELECTRICAL SAFETY

GROUNDING INSTRUCTIONS:

In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This tool is

equipped with an electric cord having an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the proper outlet

installed by a qualified electrician.

Improper connection of the

equipment-grounding conductor

can result in a risk of electric shock. The

conductor with a green outer surface,

with or without yellow stripes, is the

equipment-grounding conductor. If repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

CAUTION!

In all cases, verify that the outlet in question is properly grounded. if you are not sure,

have a licensed electrician check the outlet.

•ALWAYS WEAR eye protection.

•DO NOT wear gloves, necktie or loose clothing.

•TIGHTEN all locks before operating.

•DO NOT mount a split workpiece.

•USE the lowest speed when starting a new workpiece.

•READ the warning label attached to the lathe.

•WHEN TURNING A WORKPIECE, always rough the wood to round form at slow

speed. If the lathe vibrates when running, there is a risk that the workpiece will

be thrown or the tool jerked from your hands.

•ALWAYS ROTATE the workpiece by hand before turning on the motor. If the

workpiece strikes the tool rest, it could split and be thrown out of the lathe.

•DO NOT allow the turning tools to bite into the wood. The wood could split or be

thrown from the lathe.

•ALWAYS POSITION the tool rest above the centreline of the lathe when shaping

a piece of stock.

•DO NOT operate the lathe if it is rotating in the wrong direction. The workpiece

must always be rotating toward you.

•BEFORE ATTACHING a workpiece to the faceplate, always rough it out to make

it as rough as possible. This minimizes vibrations while the piece is being

turned. Always fasten the workpiece securely to the faceplate. Failure to do so

could result in the workpiece being thrown from the lathe.

•POSITION your hands so that they will not slip onto the workpiece.

•REMOVE all loose knots in the stock before mounting it between the centres or

on the faceplate.

•DO NOT LEAVE A RUNNING LATHE UNATTENDED. Leave the work area only after

the motor has come to a full stop.

•HANG your turning tools on the wall beyond the tailstock end of the lathe. Do not

lay them on the bench so that you must reach over the revolving workpiece to

select them.

•KEEP A FIRM HOLD and remain in control of the cutting tool at all times. Take

special precautions when shaping a section of stock in which knots or voids

are found.

•COMPLETE the hand-sanding of all workpieces before removing them from the

lathe.

•DISCONNECT TOOLS before servicing and when changing accessories, such

as blades, bits, cutters, and the like.

SAFETY GUIDELINES

9

8

SAFETY GUIDELINES

headline bars

continuation tabs

notes

warnings

headline bars

continuation tabs

notes

warnings

model no. 055-6793-6 | contact us 1-800-689-9928