9

SAFETY GUIDELINES

8

SAFETY GUIDELINES

model no. 055-6789-8 | contact us 1-800-689-9928

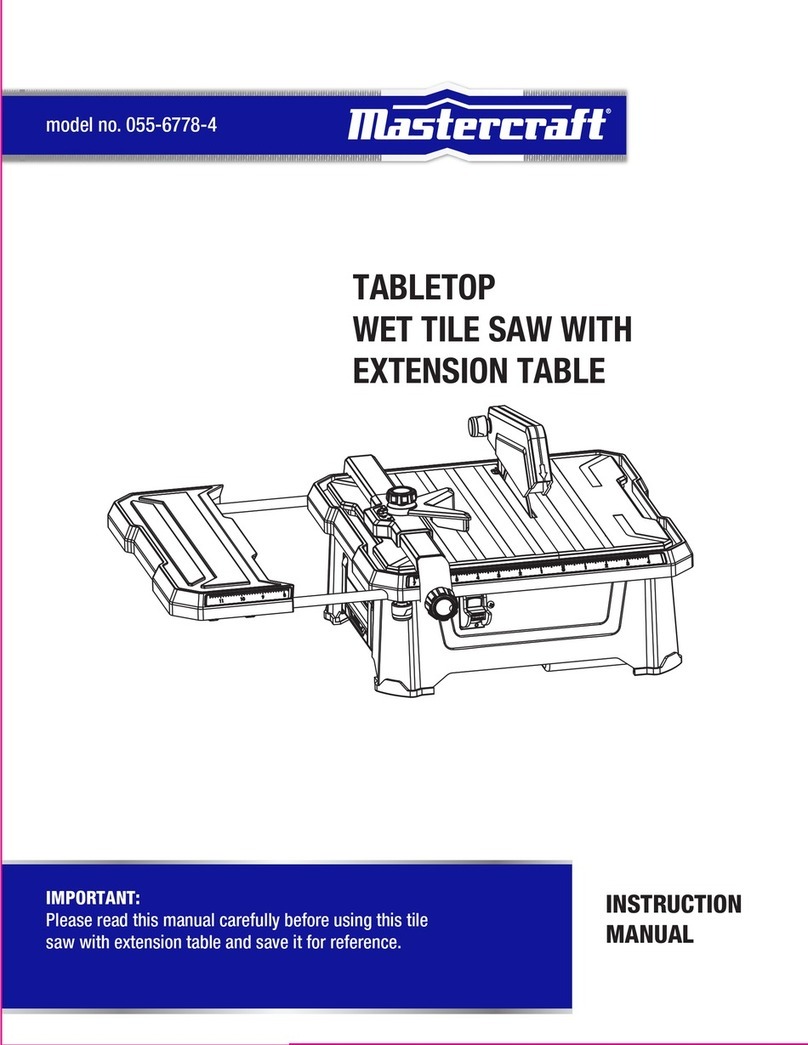

WARNING!

For your own safety, read instruction manual before operating saw.

• Wear eye protection.

• Use splash guard for every operation for which it can be used.

• Disconnect saw before servicing, when changing cutting wheels and cleaning.

• Use tool only with smooth edge cutting wheels free of openings and grooves.

• Replace damaged cutting wheel before operating.

• Do not fill water tank above water fill line.

be carefully checked to determine that it will operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts, breakage of parts, mounting and any other

conditions that may affect operation. A guard or other part that is damaged should be properly repaired

or replaced.

• Only the maintenance work and troubleshooting activities described in these instructions may be carried

out. All other work must be carried out by an expert.

• Conversions, unauthorized modifications and the use of non-approved parts are prohibited.

PRODUCT-SPECIFIC SAFETY WARNINGS

• Make sure that you always stand to the side of the cutting disc.

• WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets or other jewelry

that may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering

to contain long hair.

• ALWAYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact-resistant lenses; they are NOT safety glasses.

• USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use

of improper accessories may cause risk of injury.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

• Use only cutting discs that are suitable for the product.

• Only use cutting discs in good working condition. Remove damaged or worn cutting discs immediately.

• Never use segmented cutting discs.

• Faults in the machine, including guards or diamond discs, should be reported as soon as they are

discovered. Never use the machine without the guard in position.

• Do not twist or bend workpieces.

• Never cut several workpieces simultaneously. Do not cut bundles made of several individual pieces. A

workpiece can get caught in the cutting disc and fly out of control.

• Never cut workpieces on which there are ropes, cords, bands, cables or wires containing such materials.

• Make regular checks to ensure that the cutting disc is correctly fastened.

• Make sure that, during the cutting operation, an adequate quantity of cooling water reaches the cutting

surfaces of the disc at all times.

• Never cut wood or metal with this saw.

• Always maintain sufficient distance from the cutting disc. Switch off the product and wait until the cutting

disc stops before removing workpieces, residual material, etc., from the work area.

• Always pull out the mains plug (disconnect the product from its power supply) before commencing work

on the product.

• A cutting disc can cause injuries, even when stationary! Use protective gloves to change the cutting disc.

• Never use lateral counter pressure to bring the cutting disc to a standstill after switching off the drive.

• Replace table insert when worn.

• Use only diamond discs recommended by the manufacturer.

• Never use blades on this machine.

• Use only diamond discs for which the maximum possible speed is not less than the maximum spindle

speed of the tool and the material to be cut.

• Maximum size of working piece should be 10 sq. ft. (1 m2).

• This tile saw should be used at an ambient temperature only between 59–80°F (15–50°C).

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. Page 12

shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge number, the heavier the cord.

STORAGE AND TRANSPORT

• Always store the product in a dry place.

• Store the product in a frost-free place.

• Protect the product from damage during transport.

• Keep the product away from children. Store the product in a place where it is safe from children and

unauthorized persons.

RESIDUAL RISKS

• Even when the product is used properly and in compliance with all the safety precautions in these

instructions for use, the following residual risks can arise:

• Touching the cutting disc in the exposed area.

• Reaching into the spinning cutting disc.

• Rebound from workpieces and workpiece parts.

• Cutting disc breaks.

• Faulty cutting disc diamond attachment being flung out.

• Hearing damage through failure to wear the requisite hearing protection.