1IT IS FORBIDDEN TO EVEN PARTIALLY REPRODUCE THE TEXT AND/OR ILLUSTRATIONS.

www.masterweld.co.uk

1. GENERAL INFORMATION........................................................................................................................... 3

1.1. PURPOSE OF THE MANUAL ......................................................................................................................................................... 3

1.2. KEY OF SYMBOLS USED .............................................................................................................................................................. 3

1.3. DEFINITION OF THE OPERATORS' QUALIFICATIONS .................................................................................................................4

1.4. GLOSSARY .......................................................................................................................................................................................5

1.5. ATTACHED DOCUMENTATION ...................................................................................................................................................... 5

1.6. WARRANTY .................................................................................................................................................................................... 5

2. SAFETY INFORMATION .............................................................................................................................. 6

2.1. RESIDUAL RISKS ............................................................................................................................................................................ 6

2.2. GENERAL SAFETY WARNINGS ................................................................................................................................................... 6

2.3. SAFETY WARNINGS FOR HANDLING, ASSEMBLY AND INSTALLATION ................................................................................... 6

2.4. SAFETY WARNINGS FOR INTENDED USE .................................................................................................................................. 7

2.5. SAFETY WARNINGS FORADJUSTMENT/MAINTENANCE .......................................................................................................... 7

2.6. SAFETY WARNINGS FOR ENVIRONMENTAL IMPACT ............................................................................................................... 7

2.7. SAFETY SIGNS PLACED ON THE MACHINE .................................................................................................................................7

3. HANDLING, ASSEMBLY AND INSTALLATION INFORMATION ............................................................... 8

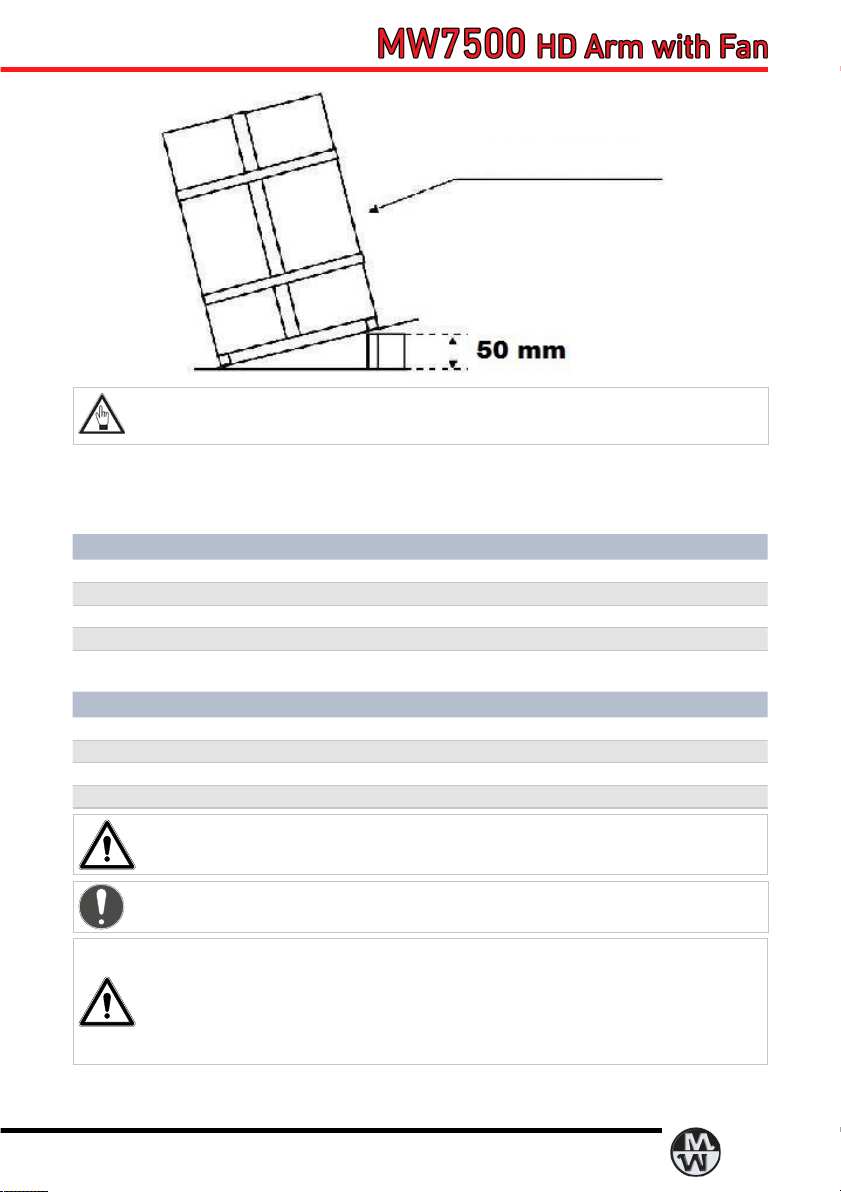

3.1. HANDLING, STORAGE AND PACKAGING ..................................................................................................................................... 8

3.2. DIRECTIONS FOR MACHINE ASSEMBLY ..................................................................................................................................... 8

3.2.1. On stand assembling............................................................................................................................................................ 11

3.2.2. Assembly on wall shelf ............................................................................................................................................................ 12

3.2.4. Hood assembly ........................................................................................................................................................................14

3.3. MOVING THE MACHINE .............................................................................................................................................................. 16

3.4. MACHINE INSTALLATION MODE ................................................................................................................................................ 17

3.5. ELECTRICAL CONNECTION MODE .............................................................................................................................................18

3.6. METHODS FOR INSTALLING OPTIONAL PARTS ........................................................................................................................ 19

3.7. CUSTOMISED CALIBRATION ....................................................................................................................................................... 23

3.7.1. Hood calibration .................................................................................................................................................................... 23

3.7.2. Joint calibration ....................................................................................................................................................................... 23

3.7.3. Joint 2 calibration .................................................................................................................................................................... 25

3.8. START-UP ..................................................................................................................................................................................... 26

4. TECHNICAL INFORMATION ................................................................................................................... 27

4.1. MANUFACTURER AND MACHINE IDENTIFICATION ...................................................................................................................27

4.1.1. Declaration of Conformity ........................................................................................................................................................28

4.1.2. Machine Identication P late................................................................................................................................................... 29

4.2. MACHINE DESCRIPTION ..............................................................................................................................................................29

4.3. OPERATING CYCLE DESCRIPTION .............................................................................................................................................. 30

4.4. TECHNICAL DATA ........................................................................................................................................................................ 31

4.4.1. Performances ...........................................................................................................................................................................31

4.4.2. Inlet dimensions ...................................................................................................................................................................... 32

4.5. SAFETY DEVICE DESCRIPTION ..................................................................................................................................................33

4.6. DESCRIPTION OF PERIMETER AREAS .................................................................................................................................... 34

5. INFORMATION ON USE................................................................................................................................ 36

5.1. RECOMMENDATIONS FOR USAGE ............................................................................................................................................ 36

5.2. INTENDED USE/IMPROPER USE ................................................................................................................................................ 37

5.2.1. Type of treated air ..................................................................................................................................................................... 37

5.2.2. Intended use in Extraction Fan environments ........................................................................................................................ 38

5.2.3. Example of EXTR code in environments containing gas ...................................................................................................... 39

5.2.4. Example of EXTR code in dusty environments ..................................................................................................................... 39

5.2.5. EXTR code for EXTRACTION FAN ARM ..................................................................................................................................39

5.3. DESCRIPTION OF CONTROLS .................................................................................................................................................... 39

5.4. WING HOOD USE ........................................................................................................................................................................ 39

5.5. IN CASE OF FIRE .......................................................................................................................................................................... 41

6. INFORMATION ON ADJUSTMENTS........................................................................................................ 42

6.1. RECOMMENDATIONS FOR ADJUSTMENTS .............................................................................................................................. 42

6.2. AIR FLOW ADJUSTMENT ..............................................................................................................................................................42