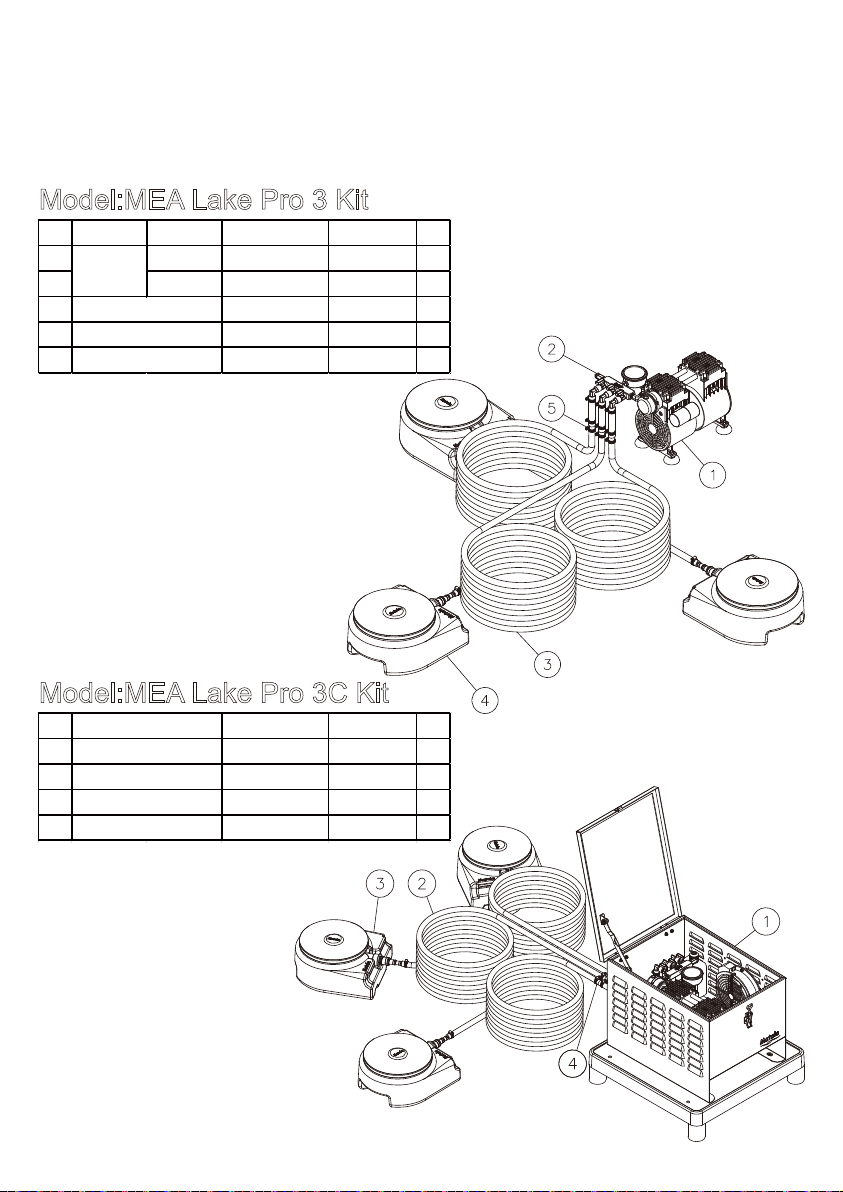

Lake and Pond Aeration is now easier than ever !

MEA Lake Pro Kits

FEATURES AND BENEFITS:

Matala Rocking Piston Compressor

˙Max. pressure up to 50 psi.(Pressure relief valve functions at 40 psi)

˙Accessories set include three ways manifold, oil filled pressure gauges and safety pressure rellef valve.

˙Oil-less non-lube piston and cylinder.

˙Permanently lubricated bearings.

˙Easy manifold design for wear resistance of the cylinder and replace piston seal of the head.

˙Reliable, balanced for smooth and low vibration operation.

˙220Volt also available on special order.

Weighted Air Hose

˙Good weather resistance.

˙Very smooth inside wall surface with very low pressure drop and high energy efficiency.

˙Weighted hose also available in 1/2”, 5/8”,3/4” and 1” for a wide variety of aeration systems.

Three Matala Diffuser Base sets

˙Allows you to mount air diffuser(s) firmly at the bottom of the pond.

˙Keeps the air diffusers up out of the mud.

˙Designed with a hollow base that can be filled with sand or gravel.

˙Choose the number of MDB11 disc diffusers for your installation needs.

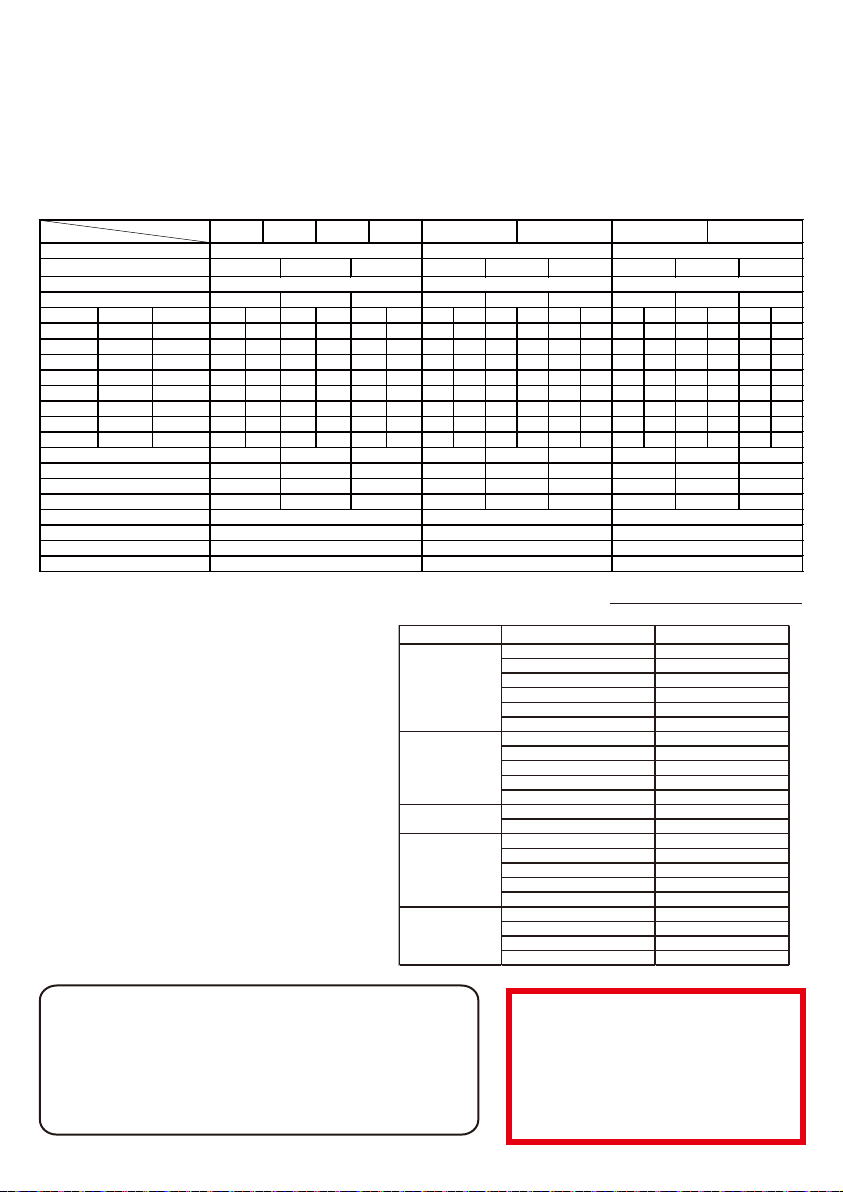

WARRANTY:

Limited Warranty :

Matala compressor will repair or replace for the original user any portion of a new compressor product

which proves defective due to materials or workmanship of compressor within 2 years of purchase date.

Contact the nearest authorized compressor dealer for warranty service.

Matala compressor shall possess the sole right to determine whether to repair or replace defective

equipment, parts or components.

THIS WARRANTY DOES NOT COVER DAMAGE DUE TO LIGHTNING OR OTHER CONDITIONS

BEYOND THE CONTROL OF compressor.

LABOR & COSTS : Matala compressor shall in no event be liable for the cost of field labor or other

charges incurred by any customer in removing and/or reaffixing any Matala compressor product, parts or

component.

THE WARRANTY WILL NOT APPLY:

(a) to defects or malfunctions resulting from failure to properly install, operate, or maintain the unit in accordance

with printed instructions provided.

(b) to failures resulting from abuse, accident, or negligence.

(c) to normal maintenance services and the parts used in connection with such service. Such as Rebuild

Kit Components and Air Filters.

(d) to units which are not installed in accordance with applicable local codes, ordinances, and good trade practices.

(e) if unit is used for purposes other than for what it was designed and manufactured for.

(f) if unit or components have been tampered with or modified in any way by an unauthorized dealer or

repair shop.

(g) Warranty does not include rebuild kits of compressor, it is recommended to replace these parts every

12 to 18 months and the parts can be obtained from an Authorized Distributor.

*Piston cup #8 for MPC-60~200

*Cylinder & O-ring #11 & #12 for MPC-60~200

*Upper/Down valve flapper & O-ring #15 & #17 for MPC-60~200, #31 for MPC-200

(h) Warranty does not include the following accessories: Oil-filled gauge #6, Air Filter/Silencer #10, Plastic

base (for cabinet) #B.

WARRANTY EXCLUSIONS : Matala compressor

SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE AFTER THE TERMINATION OF THE WARRANTY PERIOD.