INSTALLATION

For permanent installations to the mains supply, it is necessary to conform to

the regulations of the local electricity authority and this would include the use

of a metal or plastic conduit to protect the cable.

Attention has been drawn to the fact that special rules may exist concerning

the installation of your pond pump (i.e. local building regulations).

These pumps must not be used in swimming pools, or areas where people are

in contact with the water.

Always disconnect the mains electricity supply whilst the equipment is being

installed, repaired, maintained or handled. Consult a qualified electrician if in

any doubt about wiring this product to the main supply.

Warning - The pond pump is provided with a thermal

cut out that temporarily switches off the pump in case of

overheating and the pump may automatically restart.

Locating your Blagdon pump

The Blagdon pump should be located on a firm and level base in the pond/

water feature in a depth of at least 10cm, but no more than 2m.

It is advisable to keep the pump off the bottom of the pond to avoid silt

entering the pump causing excessive wear and increasing pre-filter cleaning.

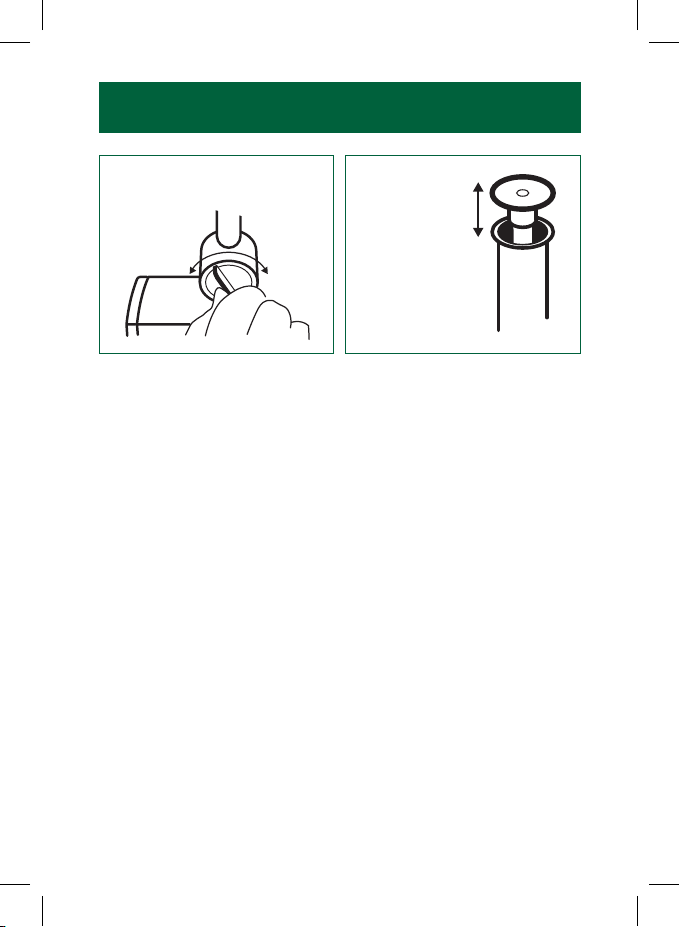

Fountain

Make sure there is ample cable from mains supply. Place pump in desired

location. Add Fountain extension pipes so fountain head is above surface of

the pond. Fountain height can now be adjusted, see ‘Adjusting flow control’

diagram below. See "Getting to know your Blagdon" for parts and descriptions.

If using the Daisy or Double Daisy Jet, cleaning of the jets will be reduced by

inserting the optional pre-filter foam included.

Tip: Ensure that any fountain, waterfall, filter or feature fitted does not empty

water out of pond/water feature. In windy conditions it may be necessary to shut

off or reduce the height of your fountain display to prevent water loss. Also see

the explanatory diagram on the top face of your Blagdon pump carton.

7

Never run the pump out of water as this may cause irreparable damage.