3.1.1 Usage limitations system

◆The space in which the unit is to be used must contain at

least 17% oxygen and must not contain any explosive gases or

vapors. In enclosed spaces where there is a risk of oxygen

deficiency, use of the unit should be avoided.

◆In case of physical effort, it is possible that a temporary

negative pressure occurs in the blower unit, resulting in a

reduction of the protection factor of the system.

◆Air speed in excess of 2m/s can affect the protection factor.

◆The ambient usage temperature should be between the limits

of -5 and +50

◆Do not use the unit in circumstances where hazardous gases

and/or vapors are present.

Warning

If the wearer of the respirator feels dizzy or uncomfortable or can

smell/taste something, he should abandon the contaminated area

immediately.

3.1.2 Usage limitations filter element

◆Used filter elements cannot be cleaned.

Warning

Never attempt to clean a filter element; the filter media may be

damaged, resulting in loss of protection.

3.1.3 Charging batteries

The battery is supplied in a non-full charged state; the charging

time for a fully discharged battery is approximately 3 hours.

The automatic setting of the charger prevents damage to the

batteries when the charging time is exceeded.

Under normal circumstances the battery can be charged and

discharged approximately 500 times.

After the battery is completely charged, the charger will switch

over to trickle charging. This will expand the lifetime of the

battery beyond 500 charge cycles. If the unit is used for more

than 8 hours a day, it is recommended that user carry a second

battery for backup.

Batteries may be charged on or off the unit.

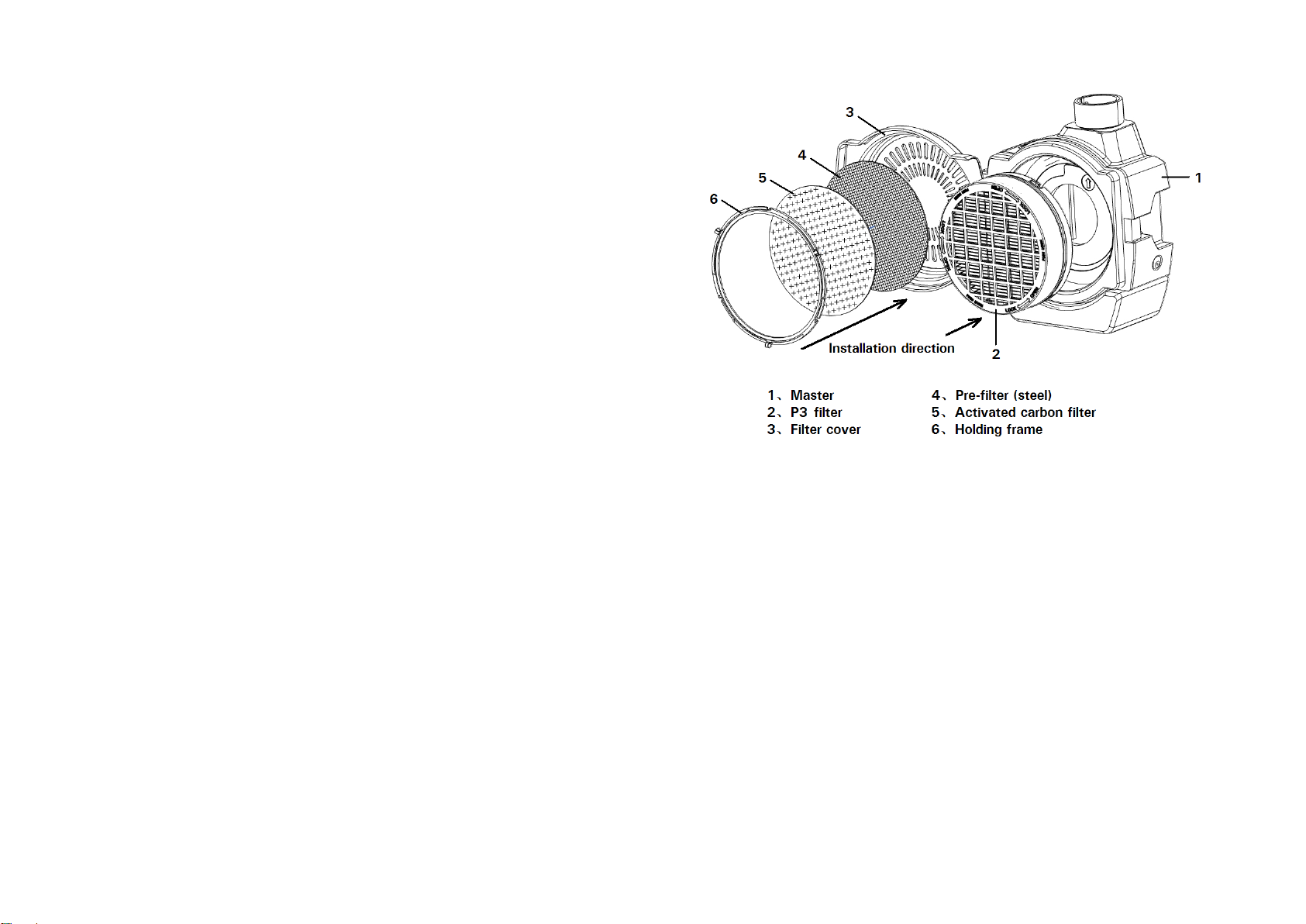

3.1.4 Filter assembling

Open the front cover by releasing the retaining clip on the side

of the unit by hand (do not use tools). Fit the filter squarely into the

power unit by aligning the three concave points of the filter box to

the three convex points in the cavity. Then press the filter hard and

rotate a small angle clockwise to lock. To unlock the filter, press it

and rotate anticlockwise.

The pre-filter and the activated carbon filter should be installed

on the inner side of the upper cover, assembled in the order and

direction indicated in Figure 1, and then pressed by the frame.

Three notches on the frame are aligned with three buckles on the

top cover. Press the frame and rotated clockwise to lock. To

disassemble them, press the frame and rotated anticlockwise to

unlock.

3.2Switching on

The unit can be switched on by pushing the ON/OFF button for

about three seconds. An alarm signal will be heard, and the

LCD will display the real statuses of air flow, filter and the

battery power. Then the unit will start on the low speed.