Page 4 284-512-350 © 1990 (Rev 6/97) Max Machinery, Inc.

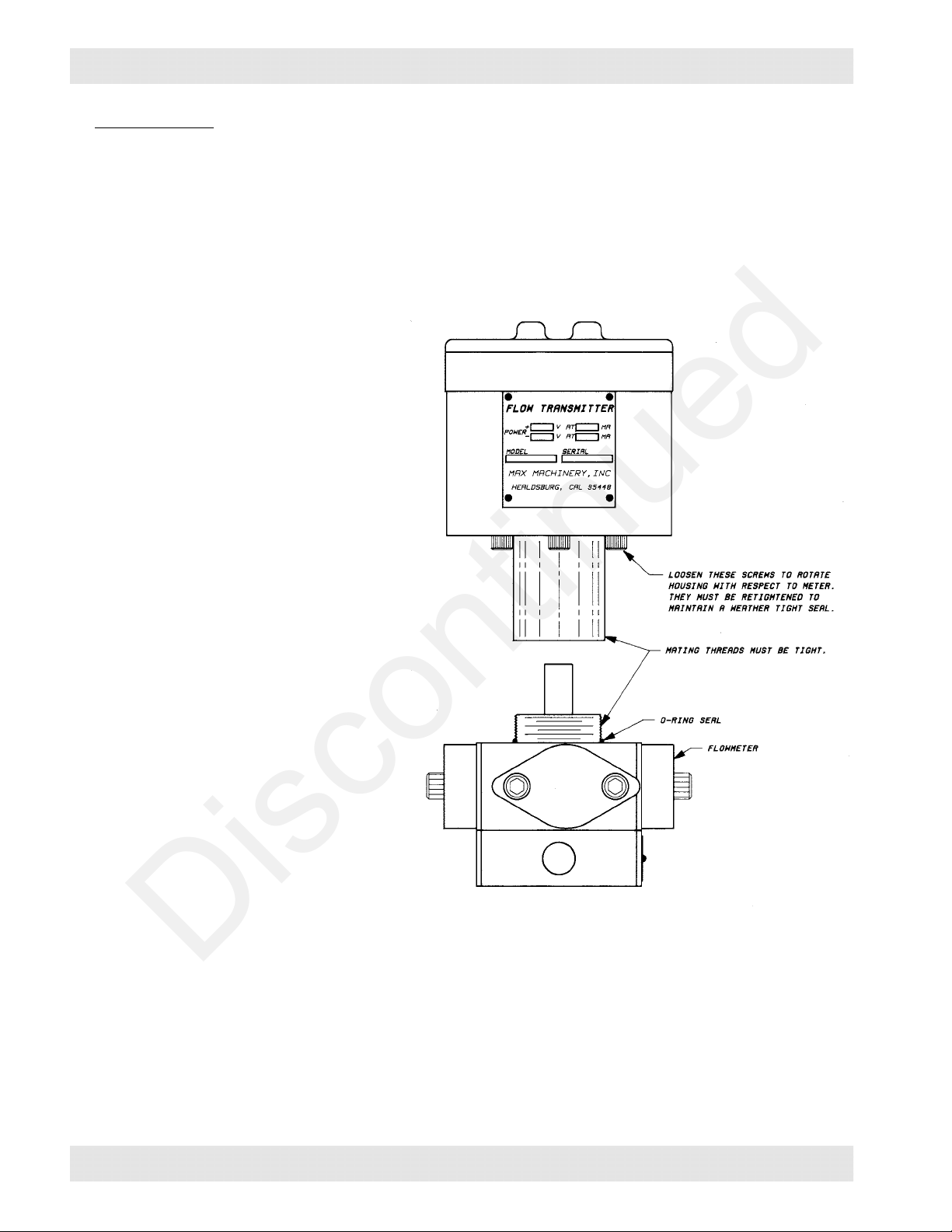

Installation

Environment: The electrical circuitry of the weather-tight, explosion-proof transmitter is

enclosed in a liquid and vapor tight enclosure. All joints are sealed by welding or by “O”-

rings. If this sealed condition is to be maintained, the conduit connection to the enclosure

should be made liquid and vapor tight by using pipe dope or a potting fitting. If a transmitter

is located outside and this precaution is not taken, moisture may form inside the housing.

This will cause the circuitry to give

an inaccurate output or possibly no

output at all. In the long run it will

cause corrosion and failure. The

amphenol connector versions of the

284 offer moderate protection from

moisture and dust, but are not totally

sealed.

The transmitter may be rotated by

loosening the screws under the

housing (see drawing on Page 5).

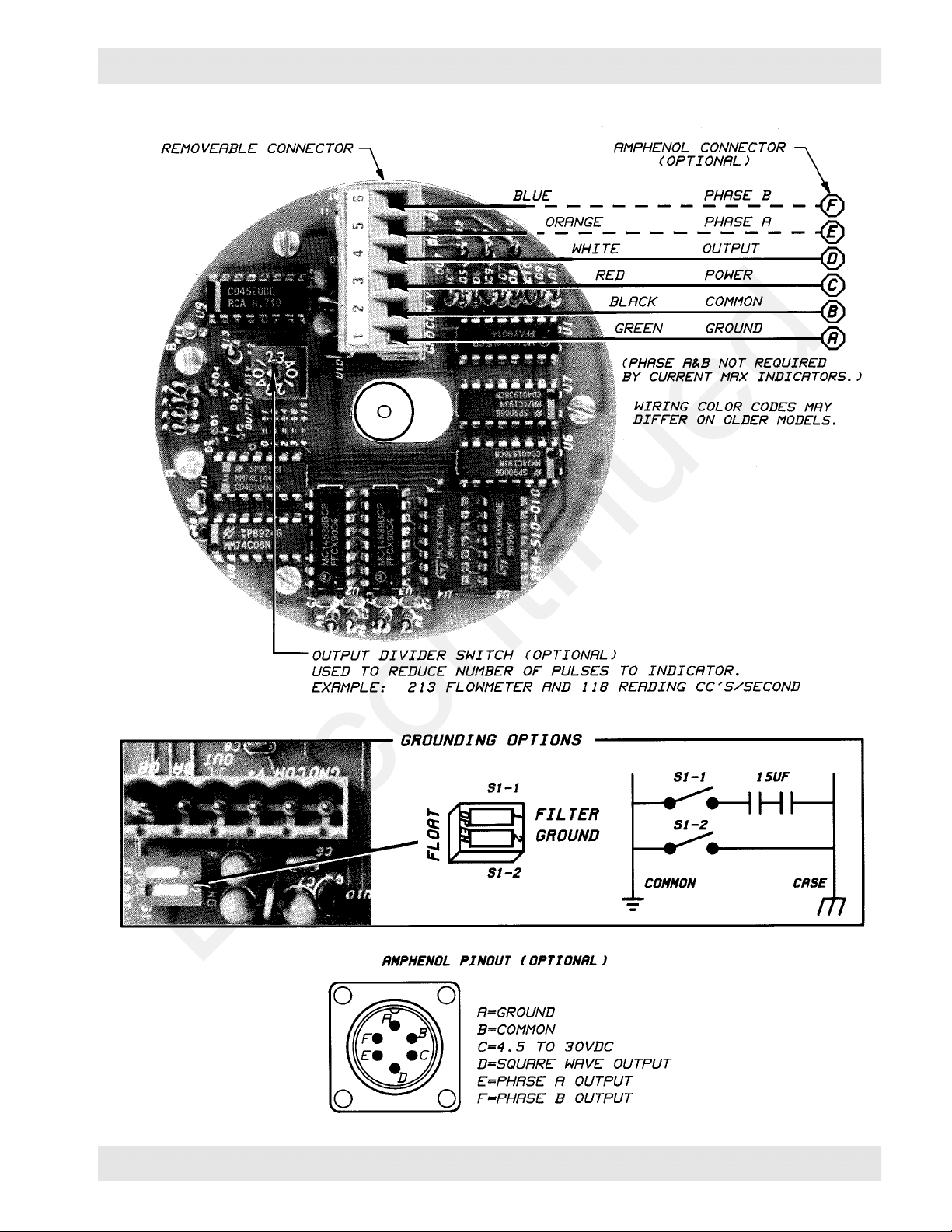

Connections: The facing page

shows the terminals and their

functions. When connecting wires to

the screw terminal versions, make

sure the lead wires do not rub on the

arbor. This arbor rotates and rubbing

wires will affect accuracy and may

eventually cause a short circuit.

Grounding: Two dip switches are

provided. The ground switch, when

activated, connects the circuit

common to the case terminal. The

Filter switch, when activated,

connects the circuit common to the

case via two back to back capacitors.

These two switches facilitate system

grounding procedures which will reduce electrical noise problems.

It is advisable to have the common of any system physically grounded at one point only. If

your system is grounded at the receiving end then you may not want to ground the common

at the transmitter end. In this case, it is advantageous to connect the circuit common to case

via the capacitors (filter). This will give some extra immunity to electrical noise.

Installation