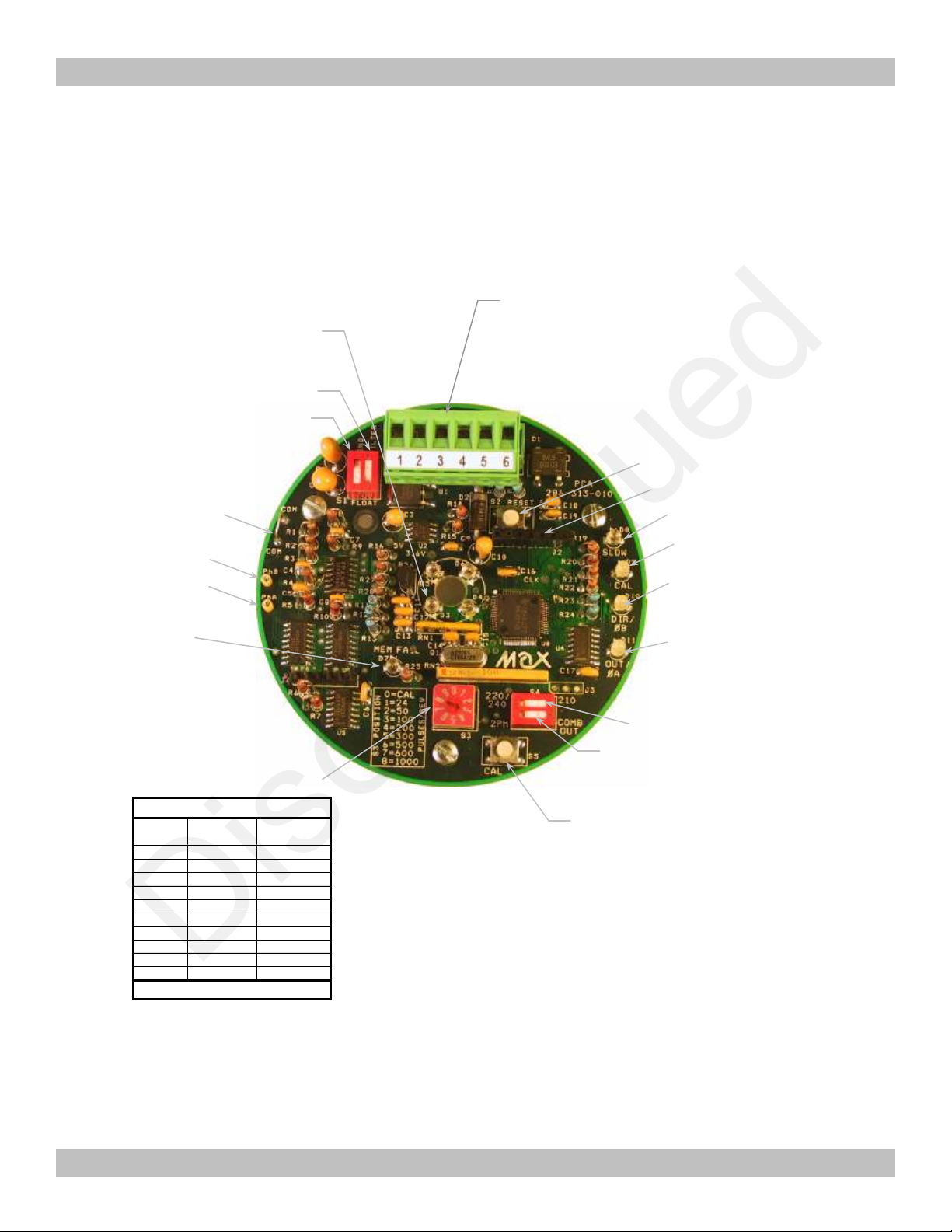

Output Indicators:

D10, D11: These bi

-

color (red, green) LEDs indicate the status of the outputs. If the 2

-

phase output

mode has been selected, the state of Phase A and Phase B are each shown on the corresponding

LEDs (‘O

UT/

A’ and ‘DIR/

B’). If the combined output mode has been selected, the LED labeled

‘OUT/

A’ shows the status of the pulse output channel, and the LED labeled ‘DIR/

B’ indicates

the direction.

Microprocessor Reset:

S2: In the event that the tachometer

does not appear to be operating correctly, resetting the

microprocessor by momentarily depressing S2 may solve the problem. While the reset button is

depressed, the ‘MEM FAIL’ LED will turn on, and if the memory is good, the LED should turn back

off when

the button is released.

RVDT Rotor Position Indication LED’s:

D3

-

D6: These LED’s provide a graphical representation of the position of the RVDT rotor. This

can be a helpful troubleshooting aid when trying to determine if a meter is turning or not. Th

e

rotational pattern observed on the LED’s corresponds directly to the rotational speed of the RVDT

rotor. At high speeds, the LED’s will just look like they are blinking; the human eye can no longer

discern the direction of motion. At very high speeds t

he blinking will not even be obvious and they

will all appear to be a constant brightness. At these higher speeds, a divide

-by-ten feature can be

activated by pressing S5 (the ‘CAL’ button, make sure S3 is not in the 0 position, otherwise the

calibration

routine will be run!). This only slows down the Rotor Position indication LEDs, the

output frequency does not change.

‘CAL’ LED:

D9: This LED changes color (red to green or green to red) 4 times per revolution while the

microprocessor is performing the

calibration routine on the stator coils. When calibration is

complete, it will turn off. See Calibration Section for more information on calibration procedures.

‘SLOW’ LED:

D8: If a calibration is initiated but the flow rate is too low to give acceptab

le results, the calibration

will be aborted, and this LED will light up red for 10 seconds. See Calibration Section for more

information on calibration procedures.

‘MEMORY FAIL’ LED:

D7: The microprocessor continually checks the integrity of its progra

m storage memory. If one or

more memory values do not read what they are supposed to, this LED will turn on. Two possible

causes of memory failure are prolonged operation/storage at temperatures exceeding the ratings and

transient voltages applied to inp

uts and/or outputs that exceed ratings. If the transmitter does not

appear to be functioning correctly and this LED is on, the unit should be sent back to the factory for

service.

Outputs, Options & Indicators

286-300-

350 © 2002,

Max Machinery, Inc.

(8)