The Series GSTC Carbon Monoxide/Nitrogen Dioxide Gas Transmitter

monitors the gas concentration in underground parking garages and loading docks.

The carbon monoxide transmitter is used to measure the exhaust of gasoline

engines, while the nitrogen dioxide transmitter is used for diesel engines. The

Series GSTC is compatible with either BACnet or MODBUS®communication

protocol, allowing the transmitter to be used with almost any building management

controller. The GSTC output is communicated over an RS-485 wire via BACnet or

MODBUS® communication protocol. To maximize the accuracy of the Series GSTC,

the sensor can be field-calibrated using the A-449 remote LCD display. When the

sensor reaches the end of its life, the display will indicate that the sensor needs to

be replaced.

BACnet and MODBUS®communication protocol recommend limiting the number of

nodes in any segment to 32. Therefore, the transceiver may be rated at one unit

load. Fractional loads are also acceptable. The Series GSTC accounts as an

eighth of a load on the MSTP network.

INSTALLATION

• The transmitter should be mounted at normal breathing height, approximately 5

to 6 ft above the floor.

• The unit may be mounted in the horizontal or vertical position. It should be

mounted in an area that is shielded from direct contact with the elements or direct

sunlight.

• Mount in an area that will prevent the sensor from having any direct contact with

water.

• The unit should be placed in an area that will give an average of the air quality.

Do not place the unit so it will receive direct engine exhaust. Prolonged exposure

to direct engine exhaust may damage the sensor.

Series GSTC Carbon Monoxide/Nitrogen Dioxide Gas Transmitter

Specifications - Installation and Operating Instructions

Bulletin AQ-GSTC

DWYE INST UMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P

.O.

BOX

373

•

MICHIGAN

CITY

,

INDIANA 46360,

U.S.A.

Fax:

219/872-9057

e-mail:

[email protected]SPECIFICATIONS

Sensor: Field replaceable

electrochemical, 4 years typical

lifespan.

ange: CO: 0 to 500 PPM, NO2: 10

PPM.

Output Drift: <5% per year in air.

Coverage Area: 5000 to 7500 sq ft

typical.

Accuracy: CO: 2% FS, NO2: 3% FS,

at the time of calibration.

esolution: CO: 1 PPM; NO2: 0.1

PPM.

Temperature Limits: -4 to 122°F (-20

to 50°C).

Storage Temperature: For best

sensor life, 32 to 68°F (0 to 20°C).

Humidity Limits: 15 to 90% R

constant; 0 to 99% R intermittent.

esponse Time: <45 s to 90% CO,

<25 s to 90% NO2.

Span and Zero Adjustment: Via

pushbutton, using optional A-449

display. Zero only via BACnet or

MODBUS®communication protocol.

Housing: UV resistant glass filled

polycarbonate.

Output Signals: BACnet MS/TP or

MODBUS®RTU (switch selectable)

communication protocol.

Power equirements: 10 to 36 VDC

or isolated 21.6 to 33 VAC.

Electrical Connection: Removable

terminal block, knock outs for conduit

fitting.

Calibration: Via pushbuttons using A-

449 auxiliary display. Span gas

concentration is field selectable.

Enclosure ating: IP64.

Weight: 1 lb (0.45 kg).

Agency Approvals: CE.

Disconnect power supply before installation to prevent electrical

shock and equipment damage. Make sure all connections are in

accordance with the job wiring diagram and in accordance with national and local

electrical codes. Use copper conductors only.

WA NING

Use electrostatic discharge precautions (e.g., use of wrist

straps) during installation and wiring to prevent equipment

damage.

Avoid locations where severe shock or vibration, excessive

moisture, or corrosive fumes are present.

Do not exceed ratings of this device, permanent damage not

covered by warranty may result.

These are general guidelines. Local laws or ordinances will take

precedence.

NOTICE

NOTICE

NOTICE

NOTICE

3-45/64

[94.06]

3-1/8

[107.95]

2-15/64

[56.75]

4-17/32

[115.09]

5-7/64

[129.78] 3-59/64

[100]

2-15/64

[57]

2-55/64

[73]

3-23/64

[85]

Wall Mount Duct MountWall Mount

Without LCD

Duct MountWall Mount

With LCD

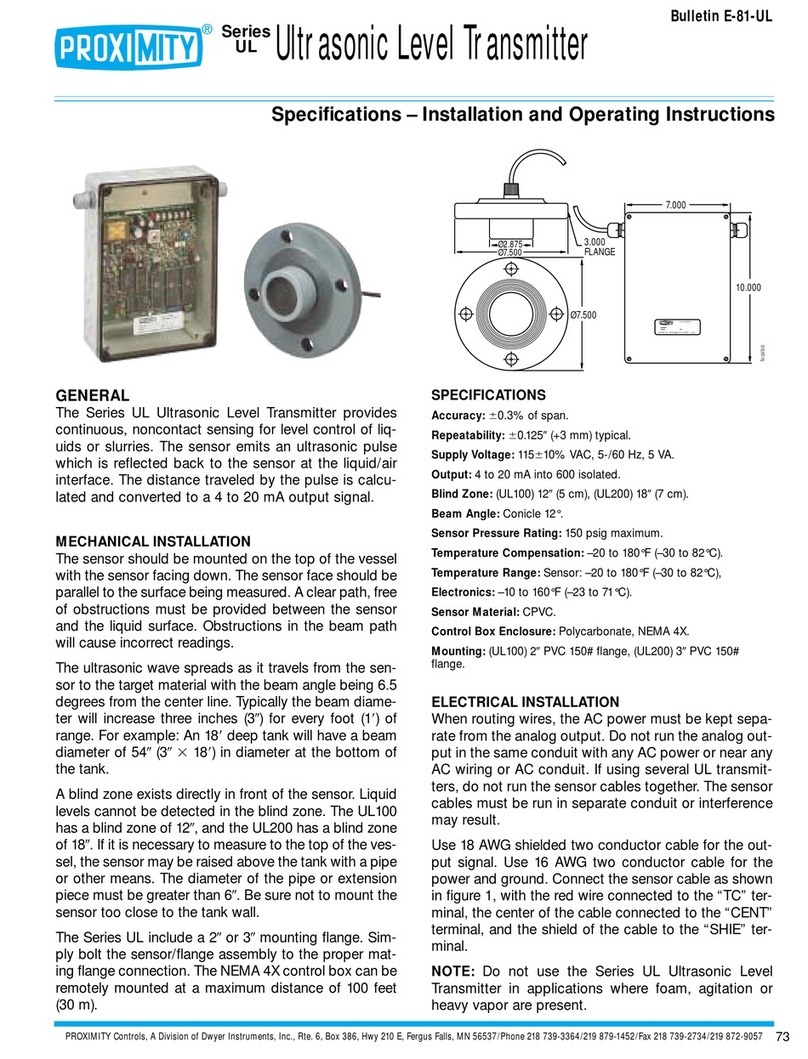

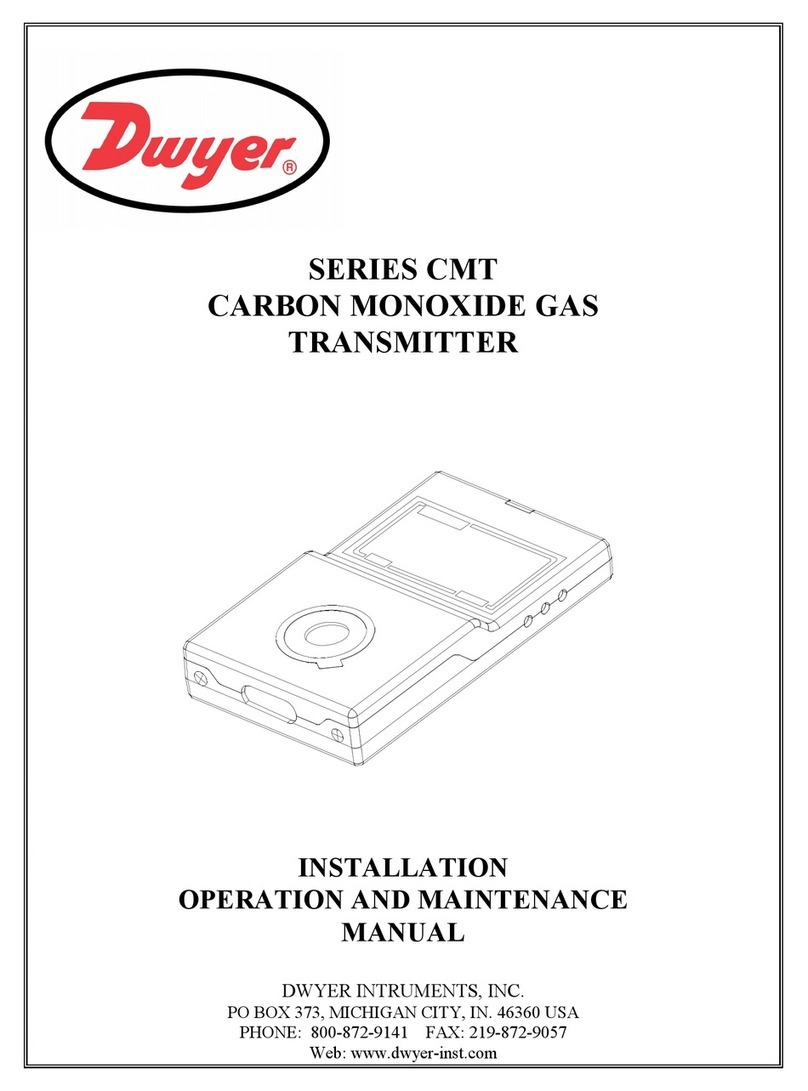

Figure 1 shows the location of the wiring terminal, 8 position DIP Switch SW1, used

for configuring the RS-485 address, the 4 position DIP Switch SW2, used for

configuring hardware and software options, sensor, span and zero adjustments,

and status LEDs.

The device provides three LEDs to indicate status and activity. The LEDs are

located to the right of DIP Switch SW1. The yellow LED indicates that the unit is

sending a BACnet or MODBUS®communication protocol. The green LED indicates

the unit is receiving a BACnet or MODBUS®communication protocol addressed to

this specific device. The red LED will flash once periodically if the BACnet or

MODBUS® communication protocol address is set incorrectly or the red LED will

flash twice periodically if the auto serial configuration is in progress.

Sensor

Span

Zero

Status

LEDs

Wiring

Terminal

DIP Switch

SW1

DIP Switch

SW2

Figure 1

The electrochemical sensors should be stored in an

environment with a minimum humidity level of 20% R . If the

sensor dries out, replacements will not be covered under warranty, but they can be

revived by allowing them to stabilize in an environment above 40% R for 10 days.

Once revived, they need to be recalibrated before use.

NOTICE