1 18062014

MAX PROP EASY

INTRODUZIONE

Grazie per aver scelto un’elica a pale orientabili MAX

PROP® EASY. Questo libretto di istruzioni servirà a

rispondere a tutte le Vostre domande sul montaggio e

sull’uso dell’elica. Vi consigliamo di leggerlo

attentamente e di fare la verifica del corretto

funzionamento dell’elica prima di montarla sulla Vostra

imbarcazione.

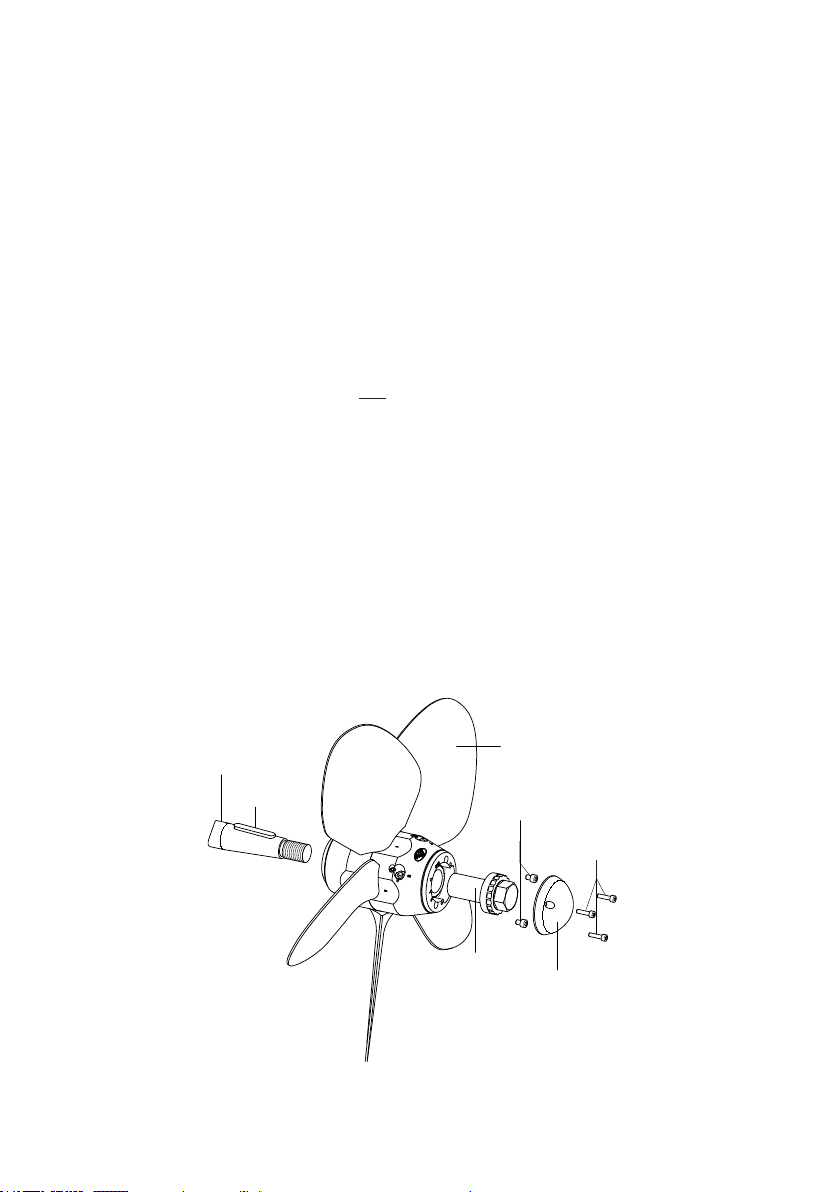

MONTAGGIO

Effettuate le varie operazioni facendo riferimento alla fig.

1. L’elica è fornita già assemblata come destrorsa o

sinistrorsa secondo l’informazione ricevuta al momento

dell’ordine, e con un determinato passo richiesto, così

che possa essere montata direttamente sull’albero

motore. Tenete presente che le parti che compongono la

MAX PROP® EASY non sono intercambiabili. Nel caso si

ricevessero contemporaneamente più eliche, sarà quindi

necessario fare molta attenzione a non mischiare i pezzi

smontati.

a) Inserite l’elica già assemblata sull’asse motore,

come fosse un’elica fissa, verificate che la linguetta

sia di misura appropriata: che abbia gioco sulla

faccia superiore per evitare di portare l’elica fuori

centro, ma senza gioco tra le superfici laterali .

b) Stringere il dado e bloccarlo mediante le due viti blocca

- dado che si situano nelle apposite sedi

c) Riempite l’elica con grasso marino attraverso gli

appositi fori usando un ingrassatore. L’elica MAX PROP®

EASY funziona in modo corretto solo se totalmente

riempita di grasso fluido. Verificare che il grasso trafili

dalle giunture rotanti tra il corpo centrale, il mozzo e le

pale, in modo da essere sicuri che tutte le superfici

rotanti siano lubrificate perfettamente. Il grasso deve

essere fluido per garantire che continuerà ad uscire tra

le superfici anche dopo anni di funzionamento.

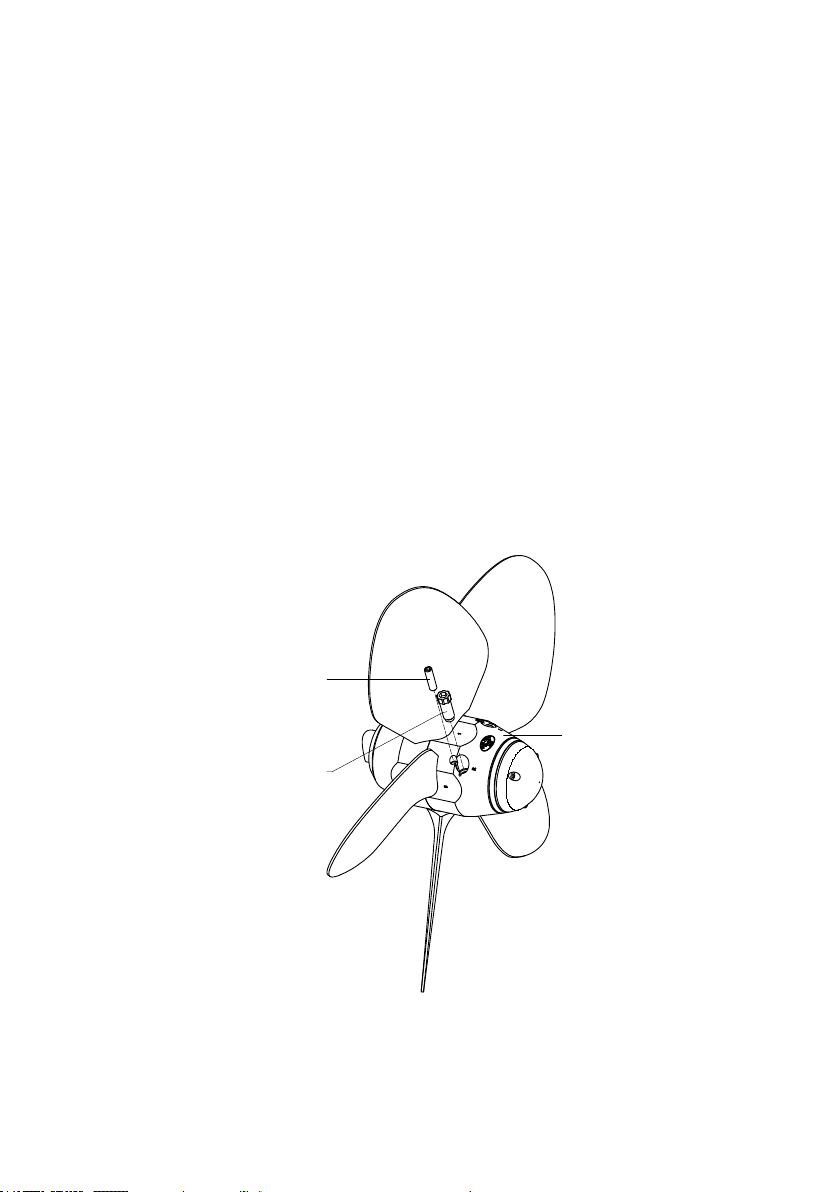

d) Orientate le pale nella loro posizione di bandiera (cioè

perfettamente allineate con l’asse del corpo

dell’elica), facendo attenzione che il loro profilo sia

come quello mostrato in fig. 2.

e) Prima di varare la barca è indispensabile effettuare le

seguenti operazioni:

•Bloccare l’albero motore.

•Verificare che le pale dell’elica ruotino liberamente

dalla posizione di marcia avanti a quella di marcia

indietro con la semplice spinta delle mani; a fine

corsa il loro angolo di inclinazione deve essere quello

prescelto.

•In posizione di bandiera le pale devono essere

perfettamente allineate ed orientate come in fig. 2

•Verificare che l’elica sia piena di grasso marino fluido

•Assicurare la protezione dell’elica contro la

corrosione galvanica applicando gli apposite anodi di

zinco sull’elica e sull’asse motore.

REGOLAZIONE DEL PASSO

Il passo della MAX PROP® EASY dipende dal diametro

dell’elica e dall’angolo αdi inclinazione delle pale. Nella

tabella di f ig. 3 sono riportati per alcuni diametri, i

passi in millimetri corrispondenti alle diverse angolazioni

delle pale

Fig. 3

by about 14% at the same speed of the boat.

a. On the body of each propeller two threaded holes (housings) are obtained, marked