Maxcess Tidland Performance Series Owner's manual

Tidland Performance Series

Crush Knifeholder

Installation, Operation and Maintenance

EN

MI 612075 1 H

CLASS II with Regulator and Gauge

TIDLAND SLITTING SOLUTIONS

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 3

TABLE OF CONTENTS

Knifeholder Safety ................................................................................................................................... 4

Product Overview .................................................................................................................................... 5

Knifeholder Orientation............................................................................................................................ 6

Class I ................................................................................................................................................. 6

Class II and III ..................................................................................................................................... 7

0° Cant Angle Setting.......................................................................................................................... 8

Crush Slitting Blade Profiles................................................................................................................ 9

Air Supply System............................................................................................................................. 10

Knifeholder Air Supply Hoses And Fittings................................................................................... 11

Installation ............................................................................................................................................. 12

Determine Mounting Dimensions...................................................................................................... 12

Knifeholder Setback .......................................................................................................................... 12

Knifeholder Geometry ....................................................................................................................... 13

Class I ........................................................................................................................................... 13

Class II .......................................................................................................................................... 14

Class III ......................................................................................................................................... 15

Install Guide Bar on Support Beam .................................................................................................. 16

Mount Knifeholder To Guide Bar....................................................................................................... 17

Manual Lock.................................................................................................................................. 17

Pneumatic Lock ............................................................................................................................ 18

Operation............................................................................................................................................... 19

Knifeholder Air Supply Pressure Vs. Down Force ............................................................................ 19

Manual Lock...................................................................................................................................... 20

Pneumatic Lock................................................................................................................................. 21

Maintenance .......................................................................................................................................... 22

Preventive ......................................................................................................................................... 22

Blade Cartridge ................................................................................................................................. 23

Installing........................................................................................................................................ 23

Removing...................................................................................................................................... 23

Knife Blade........................................................................................................................................ 24

Removing...................................................................................................................................... 24

Reinstalling ................................................................................................................................... 24

Lubrication Schematic....................................................................................................................... 25

Torque Values................................................................................................................................... 26

Class I ........................................................................................................................................... 26

Class II and III ............................................................................................................................... 27

Knifeholder Assembly Diagrams and Parts........................................................................................... 28

Class I – WR ..................................................................................................................................... 28

Class I – WOR................................................................................................................................... 29

Class II – WR .................................................................................................................................... 30

Class II – WOR.................................................................................................................................. 31

Class III – WR ................................................................................................................................... 32

Class III – WOR ................................................................................................................................ 33

Disassembly Instructions....................................................................................................................... 34

Reassembly....................................................................................................................................... 35

Troubleshooting..................................................................................................................................... 36

Slit Quality ......................................................................................................................................... 36

Knifeholder Performance .................................................................................................................. 37

Control Body and Blade Cartridge Interchangeablility Chart................................................................. 38

Recommended Accessories.................................................................................................................. 39

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 4

KNIFEHOLDER SAFETY

Important!

The Tidland Performance Series Knifeholder intended use is to produce a slit with an anvil system.

There is no other intended purpose.

Read and understand all instructions before operating the knifeholder. Failure to follow instructions

may cause the knifeholder to function incorrectly and can cause serious injury.

The knifeholder contains spring-loaded components. While operating the knifeholder, follow all existing

plant safety instructions and/or requirements.

Always wear stainless steel protective gloves when changing or removing the knife blade.

Sharp knives can cause serious injury. Do not put hands in machines. Compliance with federal, state,

and local safety regulations is your responsibility. Be familiar with them and always work safely.

Receiving and Unpacking

Handle and unpack the equipment carefully. Upon arrival, check shipment against the packing list.

Promptly report to the carrier any damaged equipment.

Equipment that will not be installed immediately should be stored in a clean, dry location.

Be careful to prevent moisture.

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 5

OVERVIEW

Tidland Performance Series Crush Knifeholder

Models WOR and WR

Class I and II Performance Series Crush Knifeholders WOR

(without regulator and gauge) and WR (with regulator and

gauge) are equipped with features that allow for improved control

of individual knifeholder operation and performance.

WR and WOR models are both equipped with an actuator switch

that extends and retracts blade cartridges independently of one

another without turning off the supplied air pressure to the

knifeholders.

Model WOR knifeholders function at the supplied air pressure

without individual down force controls. For best crush

performance results, Tidland recommends the use of individual

air pressure regulators for each knifeholder.

Model WR features a self-contained pressure regulator and air

gauge that allows the operator to control the down force for

individual knifeholders. Individual air pressure control at each

knifeholder counterbalances variations in blade radii and blade

condition, allowing for more consistent slit quality across the

web.

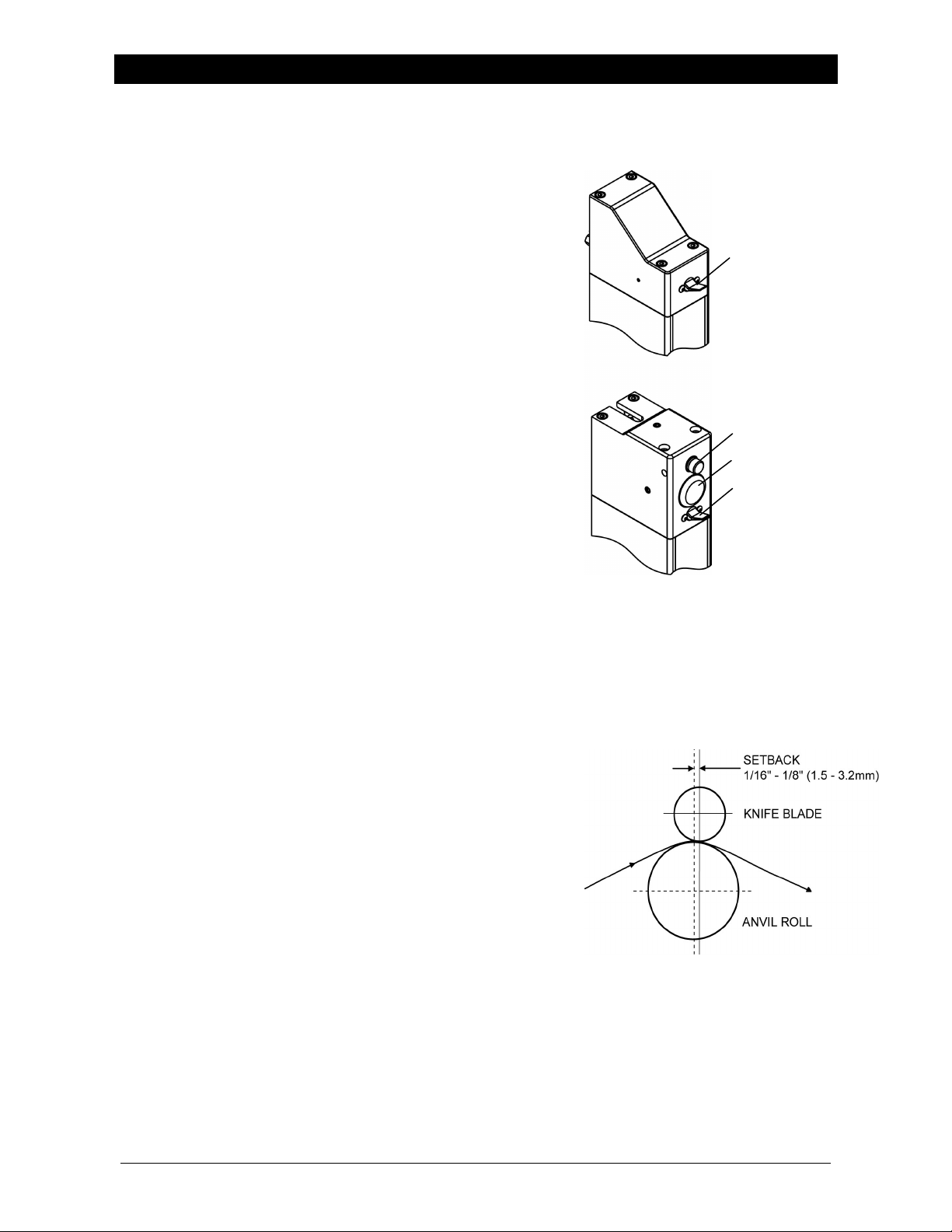

Crush Slitting

•Score slitting, often referred to as "crush" slitting in

international markets, is a common method employed in web

separation and is normally configured for a wrap-slitting

mode instead of a tangent web path.

•Crush slitting requires the anvil roll hardness to exceed the

knife blade hardness by 4 to 6 Rc points. An anvil roll at

Rockwell 64c is usually considered minimum.

•When configuring crush slitters, it is important that the

centerline through the knife blade be placed slightly

downstream of the centerline through the anvil roll and

parallel to blade cartridge travel. This prevents lateral blade

tracking. The goal is to have a slight castering effect. The

actual offset is not critical; a reasonable offset is between

1/16" to 1/8".

•Tidland-Camas offers design assistance regarding your

Crush Slitting System requirements. (1-800-426-1000)

KNIFEHOLDER

A

CTUATOR SWITCH

KNIFEHOLDER

A

CTUATOR SWITCH

GAUGE

A

IR PRESSURE

REGULATOR

WOR

WR

CLASS II SHOWN

WRAP SLITTING MODE

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 6

WOR – without Regulator and GaugeWR – with Regulator and Gauge

1

8

3

2

5

7

4

14

10

9

6

11

11

7

13

1

12

14

8

6

4

10

9

ORIENTATION

Knifeholder Components

Class I

ITEM DESCRIPTION FUNCTION

1 Control Body Holds blade cartridge

2 Air Pressure Regulator (WR only) Controls knifeholder down force (0-60 psi)

3 Air Pressure Gauge (WR only) Air pressure reference ((0-60 psi)

4 Lock Screw Fastens blade cartridge to control body

5 Safety Lock Latch Assembly Blade cartridge-to-control body locator and safety lock

6 Bellows Prevents foreign matter from entering knifeholder

7 Air Supply Fitting See Air Hose Fitting Chart , page 11.

8 Knifeholder Actuator Switch Down – extends blade cartridge

Up – retracts blade cartridge

9 Knife Blade Lock Latch Stops blade rotation when removing or replacing blade

10 Blade Cartridge Holds knife blade

11 Knife Blade Crush cutter – slits web material

12 Blade Clamp Secures knife blade to blade cartridge

13 Blade Clamp Fasteners Secures blade clamp to blade cartridge

14 Knifeholder Mount Assembly Mounts knifeholder to guide bar

Part numbers for all models begin on page 28.

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 7

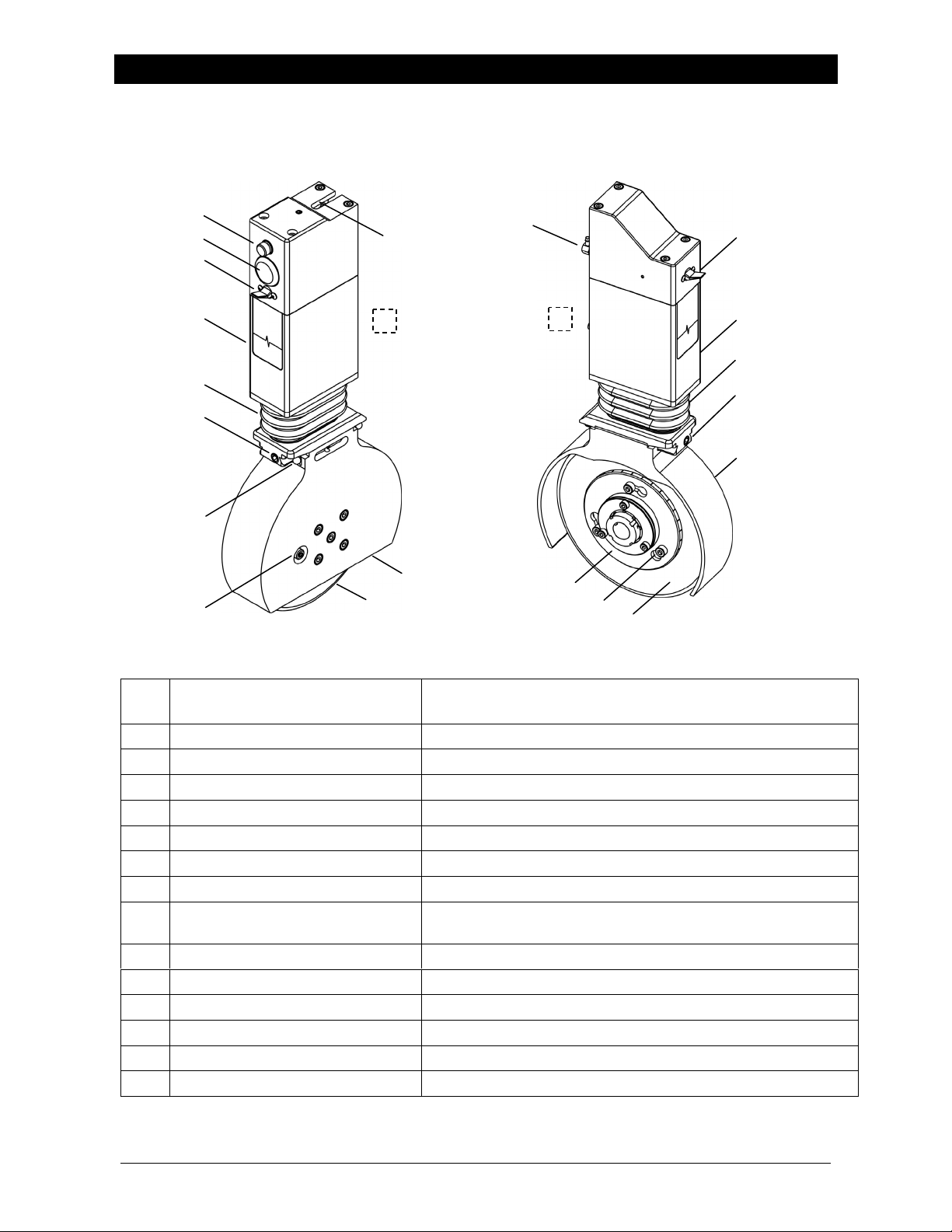

ORIENTATION

Knifeholder Components

Class II and III

ITEM DESCRIPTION FUNCTION

1 Control Body Holds blade cartridge

2 Air Pressure Regulator Controls knifeholder down force (0-60 psi)

3 Air Pressure Gauge Air pressure reference (0-60 psi)

4 Lock Screw Fastens blade cartridge to control body

5 Safety Lock Latch Assembly Blade cartridge-to-control body locator and safety lock

6 Bellows Prevents foreign matter from entering knifeholder

7 Air Supply Fitting See Air Hose Fitting Chart, page 11.

8 Knifeholder Actuator Switch Down – extends blade cartridge

Up – retracts blade cartridge

9 Knife Blade Lock Latch Stops blade rotation when removing or replacing blade

10 Blade Cartridge Holds knife blade

11 Knife Blade Crush cutter – slits web material

12 Blade Clamp Secures knife blade to blade cartridge

13 Blade Clamp Fasteners Secures blade clamp to blade cartridge

14 Knifeholder Mount Assembly See Mount Knifeholder to Guide Bar, p. 17-18

Part numbers for all models begin on page 28.

WR – with Regulator and Gauge WOR – without Regulator and Gauge

1

8

3

2

6

5

11

7

4

14

10

9

7

13

1

12

14

8

6

4

10

11

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 8

A

LIGNMENT BUSHING ASSEMBLY

Do not loosen screws.

KNIFEHOLDER LOWER BODY

BELLOWS

DOVETAIL

A

LIGNMENT ROD

PISTON GUIDE

DOVETAIL LOCK ASSEMBLY

CAUTION! Do not remove rods from dovetail.

A

LIGNMENT ROD BUSHING

PISTON GUIDE ROD BUSHING

ORIENTATION

0° Cant Angle Setting

The 0°cant angle setting on the Alignment Bushing Assembly is factory set using the four

screws at the bottom of the lower body. To maintain the alignment, do not remove or loosen

the screws.

KNIFEHOLDER LOWER BODY

A

LIGNMENT BUSHING ASSEMBLY

Do not loosen screws.

DOVETAIL LOCK ASSEMBLY

EXPLODED VIEW

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 9

ORIENTATION

Crush Slitting Blade Profiles

•These blade profiles should be viewed as reference points in determining the optimum profile for

any given material.

•Smaller tip radii and acute angles result in rapid tip fracture and anvil roll grooving.

•Larger tip radii and included angles require more force to slit.

•To reduce chipping and rapid dulling of blades, it is important to remove burred edges from

resharpened blades.

•Make sure to grind the blade edge smooth to avoid dust formation during the slitting process.

•See also: Knifeholder Supply Pressure vs. Down Force Chart on page 19.

www.maxcessintl.com Tidland Performance Series Crush Knifeholder MI 612075 1 H

Page 10

ORIENTATION

Air Supply System

Tidland Corporation recommends:

•the use of a filtered and regulated pneumatic system to prevent airborne oil or water from

contaminating the knifeholders. Clean, non-lubricated, dry air is required for optimal performance

of the knifeholder.

•the use of individual regulators for each knifeholder for improved blade life and cut quality

performance.

Individual air pressure settings will depend on blade conditions and web material.

Note: The WOR Model with pneumatic mount knifeholder requires two manifolds.

•One supplies the pneumatic mount;

•The other supplies each knifeholder independently for variable air pressure regulation.

(See Air Hose Fitting Chart on page 11.)

Part No. 520984 air filter system components include:

A - Quick exhaust valve with muffler

B - 3-way manual valve with muffler

C - Coalescing filter

D - 5 micron air filter / pressure regulator with gauge

E - 3/8 (9.52mm) supply air lines

Model WOR with pneumatic mount requires two filter systems.

Other manuals for Tidland Performance Series

1

This manual suits for next models

2

Table of contents

Popular Kitchen Appliance manuals by other brands

Tayama

Tayama TYG-35AF instruction manual

AEG

AEG 43172V-MN user manual

REBER

REBER Professional 40 Use and maintenance

North American

North American BB12482G / TR-F-04-B-NCT-1 Assembly and operating instructions

Presto

Presto fountain popper instruction manual

Westmark

Westmark 1035 2260 operating instructions