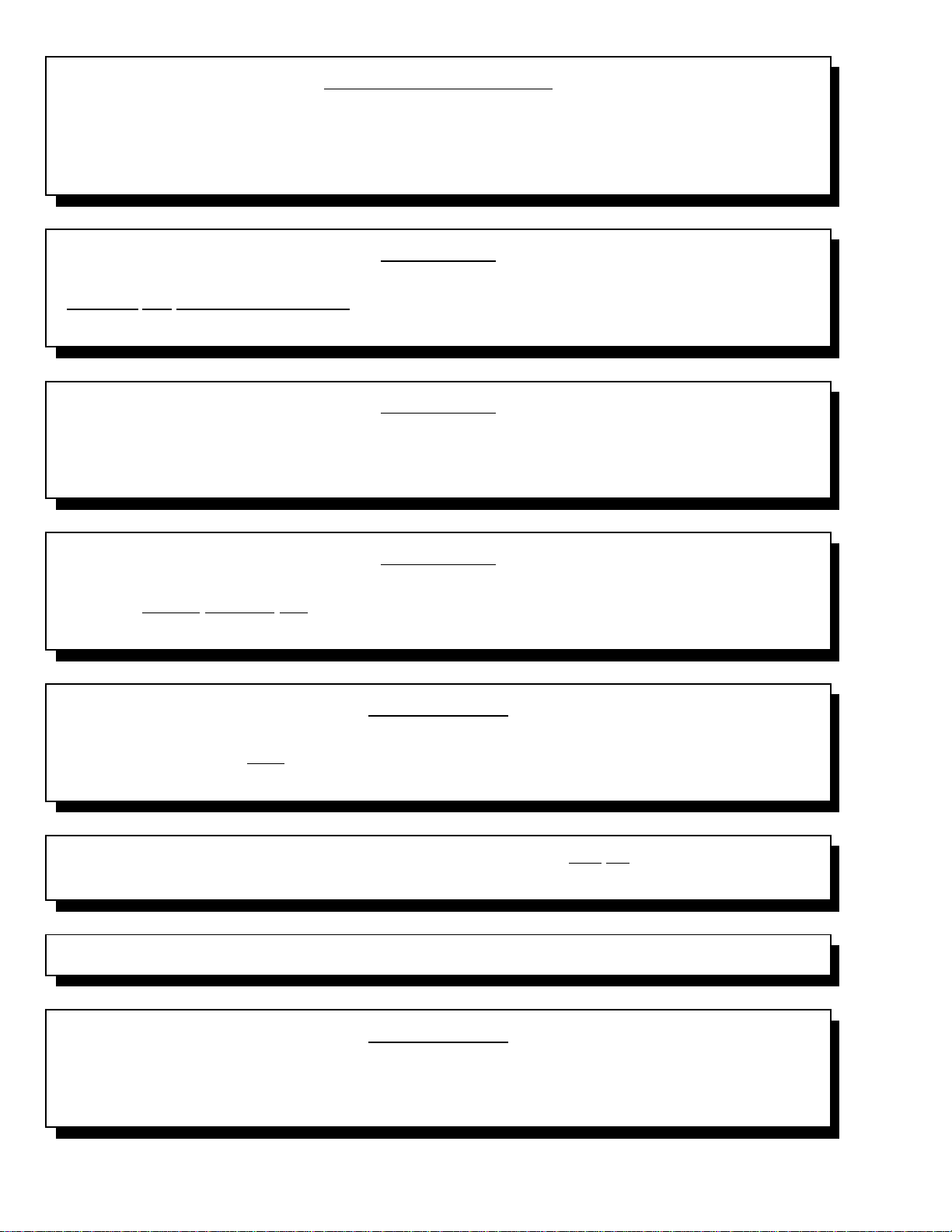

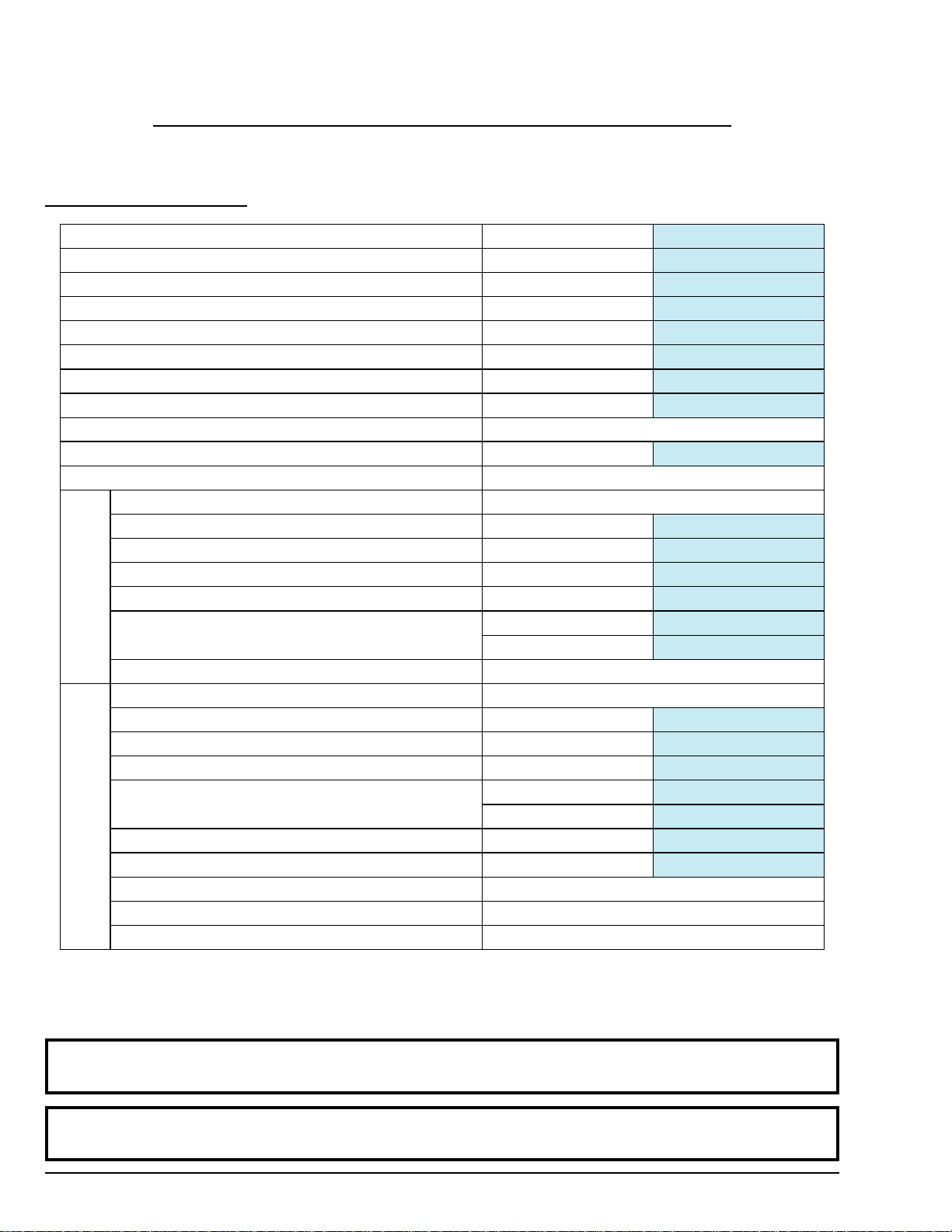

6113261 -1

MAXIMUM CAPACITY (DRY WEIGHT) 200 lb 90.9 kg

TUMBLER DIAMETER 62-1/2 158.75 cm

TUMBLER DEPTH 42 106.7 cm

TUMBLER VOLUME 74.5 cu ft 2,109.60 L

TUMBLER / DRIVE MOTOR 3 hp 2.24 kW

DOOR OPENING (DIAMETER) *36-3/4 w x 43 h 93.3 cm x 109.2 cm

DOOR SILL HEIGHT – LEVEL 37-1/4 94.6 cm

COMPRESSED AIR VOLUME 9 cfh 0.25 cmh

COMPRESSED AIR CONNECTION ** 3/8 F.N.P.T.

EXHAUST CONNECTION (DIAMETER) 20 50.8 cm

WATER CONNECTION *** 3/4 F.N.P.T.

VOLTAGE AVAILABLE 208-575V 3ø 3,4w 50/60 Hz

BLOWER / FAN MOTOR (REAR / SIDE EXHAUST) 7-1/2 hp / 15 hp 5.6 kW / 11.2 kW

APPROXIMATE NET WEIGHT 3,370 lb 1,529 kg

APPROXIMATE SHIPPING WEIGHT 3,670 lb 1,664 kg

HEAT INPUT 650,000 Btu/hr 163,810 kcal/hr

AIRFLOW 60 Hz 5,300 cfm 150.08 cmm

50 Hz 4,417 cfm 125.07 cmm

INLET PIPE CONNECTION 1-1/2 F.N.P.T.

VOLTAGE AVAILABLE 208-575V 3ø 3,4w 50/60 Hz

BLOWER / FAN MOTOR 15 hp 11.2 kW

APPROXIMATE NET WEIGHT 3,625 lb 1,644 kg

APPROXIMATE SHIPPING WEIGHT 3,925 lb 1,780 kg

AIRFLOW 60 Hz 6,500 cfm 184.06 cmm

50 Hz 5,417 cfm 153.38 cmm

STEAM CONSUMPTION 890 lb/hr 404.5 kg/hr

OPERATING STEAM PRESSURE 125 psi max 8.6 bar

BOILER HORSEPOWER (NORMAL LOAD) 27 Bhp

SUPPLY CONNECTION 1-1/2 M.N.P.T.

RETURN CONNECTION 3/4 M.N.P.T.

Shaded areas are stated in metric equivalents 07/16/03

* Dryer must be provided with clean, dry and regulated 80 psi +/- 10 psi (5.51 bar +/- 0.69 bar) air supply.

** Height is 43-inches (109.22 cm) maximum at the center of the door.

*** Water supply must be 40 psi +/- 20 psi (2.75 bar +/- 1.37 bar) for fire suppression system to operate properly.

NOTE: Dryers must be pro ided with a clean, dry, regulated 80 psi +/- 10 psi (5.51 bar +/- 0.65 bar)

air supply (equi alent olume = 9 cfh [0.26 cmh]).

NOTE: The manufacturer reser es the right to make changes in specifications at any time, without notice or

obligation.

SECTION II

SPECIFICATIONS AND TILTING DIMENSIONS

A. SPECIFICATIONS

Gas

St am